This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

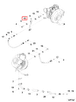

The Turbocharger Coolant Drain Tube (5363659) by Cummins is designed to facilitate the efficient operation of heavy-duty truck engines. Its purpose is to manage the flow of coolant within the turbocharger system, ensuring optimal performance and longevity of the turbocharger. This part is integral to maintaining the engine’s efficiency by regulating temperature and preventing overheating 1.

Basic Concepts

Turbochargers operate by compressing the air entering the engine, which allows for more fuel to be burned and thus increases power output. A coolant system is necessary to maintain the turbocharger’s efficiency and longevity by managing the heat generated during operation. The coolant absorbs excess heat, which if left unchecked, could lead to decreased performance and potential damage to the turbocharger 2.

Function and Operation

The Turbocharger Coolant Drain Tube operates within the cooling system by providing a pathway for coolant to flow to and from the turbocharger. It interacts with the engine’s coolant system, allowing for the circulation of coolant through the turbocharger housing. This process helps in dissipating heat, maintaining the turbocharger’s operational temperature within a safe range, and ensuring consistent engine performance 3.

Key Features

The Turbocharger Coolant Drain Tube is characterized by its durable material composition, which is designed to withstand the high temperatures and pressures within the engine compartment. Its design includes precise fittings and connections that ensure a secure and leak-free installation. Unique attributes such as reinforced sections enhance its performance and reliability under demanding conditions 4.

Benefits

The Turbocharger Coolant Drain Tube offers several advantages, including improved engine performance through effective heat management. Its design contributes to the enhanced durability of the turbocharger by preventing overheating. Additionally, the efficient maintenance facilitated by this component can lead to potential cost savings over time, as it helps in reducing the need for frequent repairs or replacements 5.

Installation and Compatibility

Proper installation of the Turbocharger Coolant Drain Tube involves ensuring that it is correctly aligned with the turbocharger and securely connected to the engine’s coolant system. Specific requirements may include the use of compatible sealants or gaskets to prevent leaks. It is important to consult the manufacturer’s guidelines to ensure compatibility with various engine models and to follow recommended procedures for installation 6.

Maintenance and Troubleshooting

Routine maintenance practices for the Turbocharger Coolant Drain Tube include regular inspections for signs of wear, leaks, or blockages. Ensuring that the coolant system is free from contaminants and that the coolant level is adequate are also important maintenance steps. Troubleshooting common issues may involve checking for proper connections, inspecting for damage, and ensuring that the coolant flow is unobstructed 7.

Common Issues and Solutions

Frequent problems associated with Turbocharger Coolant Drain Tubes can include leaks or blockages within the system. Solutions for addressing these issues may involve tightening connections, replacing damaged sections, or flushing the system to remove any obstructions. Regular maintenance and prompt attention to any signs of trouble can help in preventing more serious issues from developing 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a strong reputation within the automotive industry, Cummins is known for its high-quality products and commitment to customer satisfaction. The development and manufacturing of the Turbocharger Coolant Drain Tube (5363659) reflect Cummins’ dedication to enhancing engine performance and reliability 9.

Turbocharger Coolant Drain Tube Compatibility with Cummins Engines

The Turbocharger Coolant Drain Tube part number 5363659, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This component plays a role in maintaining the efficiency and longevity of the turbocharger by facilitating the drainage of coolant, thereby preventing coolant accumulation that could lead to overheating and potential damage.

QSL9 Engines

The QSL9 series engines benefit from the Turbocharger Coolant Drain Tube part 5363659. This part ensures that the coolant is effectively drained from the turbocharger, maintaining optimal operating conditions and preventing any coolant-related issues that could compromise engine performance.

CM2350 Engines

In the CM2350 engines, the Turbocharger Coolant Drain Tube part 5363659 is integral to the cooling system. It ensures that the coolant is properly drained, which is essential for maintaining the turbocharger’s efficiency and preventing overheating. This part is specifically engineered to fit the CM2350 engines, ensuring a precise and reliable fit.

L102 Engines

The L102 engines also utilize the Turbocharger Coolant Drain Tube part 5363659. This component is designed to integrate smoothly with the L102 engine’s cooling system, ensuring that the coolant is effectively managed and drained. This helps in maintaining the turbocharger’s performance and preventing any potential damage due to coolant accumulation.

By ensuring that the Turbocharger Coolant Drain Tube part 5363659 is correctly installed in these engines, users can maintain the integrity of the cooling system and enhance the overall performance and reliability of the engines.

Role of Part 5363659 Turbocharger Coolant Drain Tube in Engine Systems

The Turbocharger Coolant Drain Tube, identified by part number 5363659, is an integral component in the turbocharger plumbing system of various engine setups. This part facilitates the drainage of coolant from the turbocharger, ensuring that any accumulated coolant is efficiently removed from the system.

In the context of turbocharger plumbing, the drain tube works in conjunction with the turbocharger housing, intercooler, and the coolant passages within the engine block. When the turbocharger is in operation, it generates significant heat. The coolant system, which includes the drain tube, plays a role in managing this heat by circulating coolant through the turbocharger housing.

Over time, coolant may accumulate within the turbocharger due to leaks or condensation. The Turbocharger Coolant Drain Tube provides a pathway for this coolant to exit the system, preventing potential issues such as coolant mixing with the lubricating oil or causing corrosion within the turbocharger components.

Additionally, the drain tube interacts with the engine’s overall coolant system, which includes the radiator, water pump, and thermostat. Efficient drainage ensures that the coolant system maintains optimal performance, reducing the risk of overheating and enhancing the longevity of the turbocharger and associated components.

Conclusion

The Turbocharger Coolant Drain Tube (5363659) is a critical component in maintaining the efficiency and reliability of heavy-duty truck engines. By facilitating the drainage of coolant from the turbocharger, it ensures optimal performance and prevents potential damage due to overheating. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential for maximizing the benefits of this Cummins part.

-

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩ -

Cummins Inc. (n.d.). Service Manual (5613229) for B6.7 CM2450 B155B engines.

↩ -

Cummins Inc. (n.d.). Service Manual (5613229) for B6.7 CM2450 B155B engines.

↩ -

Cummins Inc. (n.d.). Service Manual (5613229) for B6.7 CM2450 B155B engines.

↩ -

Cummins Inc. (n.d.). Service Manual (5613229) for B6.7 CM2450 B155B engines.

↩ -

Cummins Inc. (n.d.). Service Manual (5613229) for B6.7 CM2450 B155B engines.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.