This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

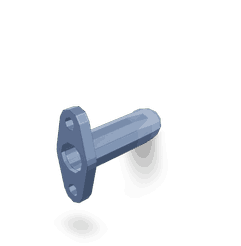

The Turbocharger Oil Drain Connector, identified by part number 5363456, is a component manufactured by Cummins, a leading provider of diesel engines and related technologies. This connector plays a role in the turbocharger system by facilitating the drainage of oil, which is vital for maintaining the lubrication and cooling of the turbocharger in heavy-duty truck engines 1.

Basic Concepts

To understand the significance of the Turbocharger Oil Drain Connector, it is important to first grasp the fundamentals of turbochargers. Turbochargers are devices that increase the efficiency and power output of diesel engines by compressing the intake air before it enters the combustion chamber. This compression allows for more fuel to be burned, resulting in enhanced engine performance. Oil lubrication is integral to the operation of turbochargers, as it reduces friction between moving parts, dissipates heat, and prevents wear and tear 2.

Function of the Turbocharger Oil Drain Connector

The Turbocharger Oil Drain Connector operates within the turbocharger system by providing a pathway for oil to be drained from the turbocharger. This process is important for several reasons. Firstly, it helps to remove contaminants and debris that may have accumulated in the oil, ensuring that the lubrication system remains clean and effective. Secondly, it allows for the replacement of old oil with fresh lubricant, which is important for maintaining optimal turbocharger performance and longevity 3.

Key Features

The Turbocharger Oil Drain Connector is designed with several features that enhance its performance and reliability. It is constructed from durable materials that can withstand the high temperatures and pressures present in the turbocharger system. The connector is also engineered with precision to ensure a secure fit and effective sealing, preventing oil leaks and ensuring efficient drainage. Additionally, it is designed to integrate seamlessly with other turbocharger components, facilitating easy installation and maintenance.

Benefits

The Turbocharger Oil Drain Connector offers several advantages that contribute to the overall efficiency and reliability of heavy-duty truck engines. By facilitating the drainage and replacement of oil, it helps to maintain the lubrication system in optimal condition, which in turn supports engine efficiency. Regular oil changes can reduce the frequency of maintenance requirements, leading to cost savings and less downtime. Furthermore, by ensuring that the turbocharger remains well-lubricated and cool, the connector contributes to the longevity of the turbocharger and the engine as a whole.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Connector is important for ensuring its effective operation. It is designed to be compatible with a range of Cummins engine models and turbocharger types, making it a versatile component for various heavy-duty truck applications. Detailed installation guidelines are provided to ensure that the connector is fitted correctly and securely, minimizing the risk of oil leaks and other issues.

Maintenance and Troubleshooting

Routine maintenance practices are important for ensuring the optimal performance of the Turbocharger Oil Drain Connector. Regular inspection and cleaning of the connector can help to prevent blockages and ensure efficient oil drainage. In the event of common issues such as oil leaks or difficulty in draining oil, troubleshooting tips are available to assist in identifying and resolving the problem. These may include checking for proper installation, inspecting for damage or wear, and ensuring that the connector is compatible with the specific turbocharger and engine model.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality, reliability, and innovation in the commercial truck industry. The company offers a comprehensive range of products and services designed to meet the diverse needs of its customers, from heavy-duty truck engines to aftermarket parts and support. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Turbocharger Oil Drain Connector for Cummins Engines

The Turbocharger Oil Drain Connector, part number 5363456, is a critical component in the maintenance and operation of several Cummins engines. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the system operates efficiently and prolonging the life of the turbocharger itself.

ISB6.7 G CM2180 B118

The ISB6.7 G CM2180 B118 engine is one of the models that benefit from the Turbocharger Oil Drain Connector. This engine is known for its robust performance and reliability, making it a popular choice in various applications. The Turbocharger Oil Drain Connector ensures that any excess oil is properly drained, preventing oil from entering the turbocharger’s bearings and potentially causing damage.

Grouping of Engines

The Turbocharger Oil Drain Connector is compatible with a range of Cummins engines, including but not limited to the ISB6.7 G CM2180 B118. This part is engineered to fit seamlessly with these engines, providing a reliable solution for maintaining the turbocharger’s oil system. The compatibility of this part across multiple engine models underscores its versatility and importance in the overall maintenance of these engines.

By ensuring that the turbocharger oil system is properly drained, the Turbocharger Oil Drain Connector helps maintain the efficiency and longevity of the engine, making it an essential component for any Cummins engine owner or technician.

Role of Part 5363456 Turbocharger Oil Drain Connector in Engine Systems

The Turbocharger Oil Drain Connector is an essential component in the maintenance and operation of engine systems, particularly those equipped with turbochargers. This connector is integral to the plumbing system of the turbocharger, facilitating the efficient drainage of oil from the turbocharger housing.

Integration with Turbocharger Plumbing

In turbocharged engine systems, the turbocharger operates at extremely high speeds and temperatures. To ensure optimal performance and longevity, the turbocharger requires a consistent supply of lubrication. The oil drain connector is a key part of the plumbing system that manages this lubrication. It allows for the controlled drainage of oil that has circulated through the turbocharger, preventing oil buildup which could lead to inefficiencies or damage.

Functionality in Turbocharger Systems

The turbocharger itself consists of a turbine and a compressor, both of which are lubricated by engine oil. As the turbocharger spins, oil is thrown outward by centrifugal force. The Turbocharger Oil Drain Connector ensures that this excess oil is efficiently returned to the engine’s oil sump. This process is vital for maintaining the correct oil levels within the turbocharger and ensuring that the turbocharger remains well-lubricated without becoming overly saturated with oil.

Maintenance and Operational Efficiency

Regular drainage of oil via the Turbocharger Oil Drain Connector is a routine maintenance procedure that helps in identifying potential issues early. For instance, an unusual amount of oil drainage could indicate a seal failure or other internal issues within the turbocharger. Additionally, efficient oil drainage contributes to the overall operational efficiency of the turbocharger, ensuring that it operates within its designed parameters and delivers the expected performance enhancements to the engine.

Conclusion

In summary, the Turbocharger Oil Drain Connector plays a significant role in the plumbing and operational integrity of turbocharged engine systems. Its proper function ensures that the turbocharger remains efficiently lubricated and operates smoothly, contributing to the overall performance and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.