4950099

Turbocharger Exhaust Inlet Connection

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4950099 Turbocharger Exhaust Inlet Connection by Cummins is a component designed to facilitate the efficient transfer of exhaust gases into the turbocharger. This part plays a significant role in the operation of heavy-duty trucks by enhancing the performance and efficiency of the engine. Understanding its purpose and significance is fundamental for maintaining and optimizing the performance of turbocharged engines.

Basic Concepts of Turbocharger Exhaust Inlet Connection

Turbochargers operate on the principle of using exhaust gases to drive a turbine, which in turn compresses the intake air before it enters the engine. The exhaust inlet connection is a critical component in this system, as it directs the flow of exhaust gases from the engine to the turbocharger’s turbine. This connection ensures that the turbine receives a consistent and efficient flow of exhaust gases, which is necessary for the turbocharger to function effectively 1.

Function and Operation

The Turbocharger Exhaust Inlet Connection operates by channeling exhaust gases from the engine’s exhaust manifold to the turbocharger’s turbine. As the exhaust gases pass through the inlet connection, they spin the turbine, which is connected to a compressor on the other side of the turbocharger. This compressor then forces more air into the engine, allowing for more fuel to be burned and thus increasing the engine’s power output. The design of the inlet connection is crucial for minimizing turbulence and maximizing the efficiency of the exhaust gas flow 2.

Key Features

The Turbocharger Exhaust Inlet Connection is characterized by several key features that contribute to its effectiveness. It is constructed from durable materials that can withstand high temperatures and pressures, ensuring longevity and reliability. The design includes precise engineering to optimize the flow of exhaust gases, reducing the risk of backpressure and improving overall engine performance. Additionally, the connection is designed to be compatible with a range of Cummins engines, ensuring versatility and ease of installation 3.

Role in Truck Operation

In the operation of a heavy-duty truck, the Turbocharger Exhaust Inlet Connection plays a vital role by enhancing engine efficiency and performance. By ensuring a smooth and efficient flow of exhaust gases to the turbocharger, this component helps to increase the engine’s power output and fuel efficiency. This is particularly important in heavy-duty applications, where maximizing performance and efficiency can lead to significant cost savings and improved operational capabilities 4.

Benefits

The advantages provided by the Turbocharger Exhaust Inlet Connection include improved fuel efficiency, increased power output, and enhanced durability. By optimizing the flow of exhaust gases, this component helps to reduce fuel consumption while increasing the engine’s power, making it an invaluable part of the turbocharger system. Its durable construction ensures that it can withstand the demanding conditions of heavy-duty truck operation, providing reliable performance over time 5.

Installation Considerations

When installing the Turbocharger Exhaust Inlet Connection, it is important to follow guidelines and best practices to ensure proper fitting and compatibility with the engine. This includes verifying that the connection is compatible with the specific engine model and ensuring that it is securely and correctly installed to prevent leaks and ensure optimal performance. Proper installation is key to maximizing the benefits of this component 6.

Maintenance and Troubleshooting

Regular maintenance of the Turbocharger Exhaust Inlet Connection is important to ensure its continued performance and durability. This includes regular inspection intervals to check for signs of wear, damage, or leaks. Common issues to watch for include cracks, corrosion, and blockages, which can affect the efficiency of the exhaust gas flow. Troubleshooting tips include checking for proper installation, ensuring compatibility with the engine, and addressing any issues promptly to prevent further damage 7.

Performance Enhancements

The Turbocharger Exhaust Inlet Connection contributes to overall engine performance by improving the efficiency of the turbocharger system. This can lead to potential improvements in horsepower and torque, enhancing the engine’s capabilities and the truck’s overall performance. By ensuring a smooth and efficient flow of exhaust gases, this component plays a key role in maximizing the engine’s potential 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions control technologies. With a strong reputation in the commercial truck industry, Cummins is known for its high-quality products and commitment to innovation. The company’s extensive product range and focus on customer satisfaction have established it as a trusted name in the industry.

Turbocharger Exhaust Inlet Connection for Cummins Engines

The Turbocharger Exhaust Inlet Connection part number 4950099, manufactured by Cummins, is a critical component in the turbocharger system of various engines. This part ensures the efficient transfer of exhaust gases from the engine to the turbocharger, which is essential for the turbocharger’s operation and the engine’s overall performance.

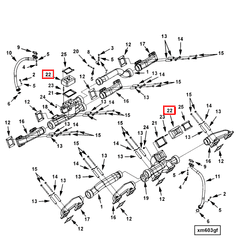

K50 Engine Group

The K50 engine series, which includes models such as the K50-C150, K50-C180, and K50-C220, utilizes the Turbocharger Exhaust Inlet Connection part 4950099. This part is designed to fit seamlessly with the exhaust manifold of the K50 engines, facilitating the smooth flow of exhaust gases. The connection is engineered to withstand high temperatures and pressures, ensuring durability and reliability under demanding conditions.

The K50 engines are known for their robust design and are commonly used in heavy-duty applications, including construction, mining, and agricultural machinery. The Turbocharger Exhaust Inlet Connection plays a pivotal role in enhancing the efficiency and power output of these engines by optimizing the turbocharger’s performance.

In the K50 engine group, the Turbocharger Exhaust Inlet Connection part 4950099 is essential for maintaining the integrity of the exhaust system and ensuring that the turbocharger operates at peak efficiency. This connection is a critical component in the overall design of the K50 engines, contributing to their reputation for reliability and performance.

Role of Part 4950099 Turbocharger Exhaust Inlet Connection in Engine Systems

The part 4950099 Turbocharger Exhaust Inlet Connection is integral to the efficient operation of modern turbocharged engine systems. This component acts as a vital link between the exhaust manifold and the turbocharger.

When the engine is running, exhaust gases exit the combustion chamber and travel through the exhaust manifold. The manifold collects these gases from all cylinders and directs them towards the turbocharger. Here, the part 4950099 plays a significant role by providing a secure and efficient connection point.

The connection ensures that the high-velocity exhaust gases are channeled into the turbocharger’s turbine with minimal loss of energy. This efficient transfer is essential for the turbocharger to spin at high speeds, compressing the intake air and thereby enhancing engine performance.

Additionally, the part 4950099 interfaces with the mounting adapter of the turbocharger. This adapter is responsible for securing the turbocharger to the engine block or cylinder head. A well-fitted connection here ensures that the turbocharger remains stable under the high stresses and temperatures it experiences.

In summary, the part 4950099 Turbocharger Exhaust Inlet Connection facilitates the smooth and efficient transfer of exhaust gases from the manifold to the turbocharger, contributing to the overall effectiveness and reliability of the engine system.

Conclusion

The Turbocharger Exhaust Inlet Connection part 4950099 by Cummins is a critical component in the turbocharger system, essential for the efficient operation of turbocharged engines. Its role in channeling exhaust gases to the turbocharger, enhancing engine performance, and ensuring durability makes it a vital part of heavy-duty truck engines. Proper installation, regular maintenance, and understanding its function are key to maximizing the benefits of this component.

-

Diesel Engine Care and Repair, Nigel Calder, The McGraw-Hill Companies, 2007

↩ -

Transmissions and Drivetrain Design, Michael Hilgers, Springer Vieweg, 2022

↩ -

Systems Engineering for Automotive Powertrain Development, Hannes Hick, Klaus Kupper, and Helfried Sorger, Springer, 2021

↩ -

Operation and Maintenance Manual, QSB4.5 CM2350 B122, Bulletin Number 4388768

↩ -

Diesel Engine Care and Repair, Nigel Calder, The McGraw-Hill Companies, 2007

↩ -

Transmissions and Drivetrain Design, Michael Hilgers, Springer Vieweg, 2022

↩ -

Systems Engineering for Automotive Powertrain Development, Hannes Hick, Klaus Kupper, and Helfried Sorger, Springer, 2021

↩ -

Operation and Maintenance Manual, QSB4.5 CM2350 B122, Bulletin Number 4388768

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.