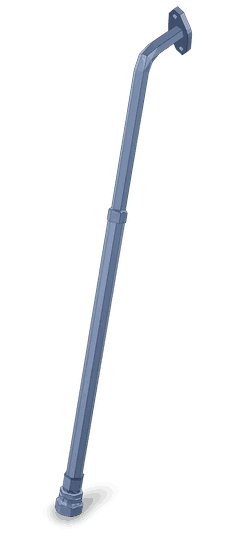

4314211

Turbocharger Oil Drain Connection

Cummins®

DISCONTINUED

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, part number 4314211, is a component manufactured by Cummins, a prominent figure in the automotive and heavy-duty truck industry. This Cummins part is integral to the turbocharger system, facilitating efficient oil management and contributing to the overall performance and reliability of the turbocharger.

Basic Concepts of Turbocharger Oil Drain Connection

Turbochargers operate by compressing the air entering the engine, allowing for more fuel to be burned and thus increasing power output. The Turbocharger Oil Drain Connection plays a role in this system by ensuring that oil used to lubricate the turbocharger’s moving parts is efficiently drained. This process is vital for maintaining the turbocharger’s efficiency and reliability, as it prevents oil buildup that could lead to decreased performance or component failure 1.

Purpose and Function

The Turbocharger Oil Drain Connection serves a specific function within the operation of a truck’s engine. It is designed to manage the oil that lubricates the turbocharger’s components, ensuring that excess oil is drained away. This management is crucial for maintaining the turbocharger’s operational temperature and efficiency, as well as for prolonging the lifespan of the turbocharger and associated engine components 2.

Key Features

The Turbocharger Oil Drain Connection by Cummins is engineered with several key features that enhance its performance and durability. Its design is tailored to fit seamlessly within the turbocharger system, ensuring efficient oil drainage. The material used in its construction is selected for its durability and resistance to the high temperatures and pressures within the turbocharger environment. Additionally, its engineering specifications are meticulously crafted to ensure compatibility and optimal performance across a range of applications 3.

Benefits

Utilizing the Turbocharger Oil Drain Connection offers several advantages. It contributes to improved turbocharger performance by ensuring that the turbocharger operates within its designed parameters. This, in turn, enhances engine efficiency, as the turbocharger can operate more effectively. Furthermore, by managing oil levels within the turbocharger, this component helps in prolonging the lifespan of the turbocharger and other engine components, reducing the need for frequent maintenance or replacement.

Installation and Compatibility

For the Turbocharger Oil Drain Connection to function correctly, it must be installed according to manufacturer guidelines. Compatibility with various turbocharger models and engine types is a consideration during installation, ensuring that the connection fits securely and operates efficiently within the system.

Maintenance and Troubleshooting

Routine maintenance of the Turbocharger Oil Drain Connection is recommended to ensure its optimal performance. This includes regular checks for leaks, ensuring the connection is secure, and verifying that oil levels within the turbocharger are managed effectively. Troubleshooting common issues, such as leaks or inefficient oil drainage, can often be addressed through proper maintenance practices and, when necessary, professional inspection or replacement.

Cummins Overview

Cummins, the manufacturer of the Turbocharger Oil Drain Connection, has a long-standing reputation in the automotive and heavy-duty truck industry. With a history of innovation and commitment to quality, Cummins is recognized for producing high-quality components that enhance the performance and reliability of engines. Their dedication to manufacturing excellence is evident in the design and functionality of the Turbocharger Oil Drain Connection, reflecting their expertise and industry leadership 4.

Conclusion

The Turbocharger Oil Drain Connection, part number 4314211, is a vital component in the maintenance and operation of turbocharged engine systems. Its role in facilitating efficient oil drainage is fundamental to the longevity and performance of the turbocharger. Proper installation, maintenance, and understanding of its function within the engine system are essential for ensuring the optimal operation of turbocharged engines.

-

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 3666130-02, Troubleshooting and Repair Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.