This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

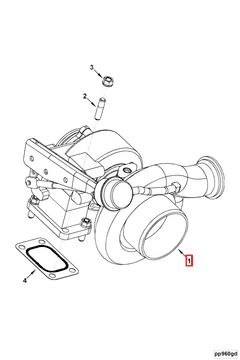

The Cummins 3970937 Turbocharger is a specialized component designed to enhance the performance and efficiency of heavy-duty truck engines. Its purpose is to increase the amount of air entering the engine, which in turn allows for more fuel to be burned, resulting in greater power output and improved fuel economy. The significance of this turbocharger in the operation of heavy-duty trucks lies in its ability to optimize engine performance under various driving conditions, contributing to overall vehicle efficiency and reliability 1.

Basic Concepts of Turbocharging

Turbocharging is a technology that uses exhaust gases to drive a turbine, which compresses incoming air before it enters the engine. This process, known as forced induction, increases the density of the air-fuel mixture, allowing the engine to produce more power without increasing its size 2. Key components of a turbocharger include the turbine, compressor, and housing. The benefits of turbocharging include enhanced engine performance, improved fuel efficiency, and increased power output, making it a valuable addition to heavy-duty truck engines.

Role of the 3970937 Turbocharger in Truck Operation

The Cummins 3970937 Turbocharger plays a specific role in the operation of heavy-duty trucks by increasing the efficiency and power output of the engine. It achieves this by compressing the intake air, which allows for more fuel to be burned in each combustion cycle. This results in enhanced engine performance, enabling the truck to handle heavier loads and operate more efficiently under various conditions. The turbocharger’s ability to maintain optimal air-fuel ratios contributes to smoother engine operation and reduced emissions 3.

Key Features of the 3970937 Turbocharger

The Cummins 3970937 Turbocharger is characterized by several key features that contribute to its performance and durability. Its design incorporates advanced materials and engineering techniques to ensure reliable operation under demanding conditions. The turbocharger features a robust turbine and compressor, precision-machined components, and a durable housing. Technological advancements such as improved bearing systems and enhanced sealing mechanisms further contribute to its performance and longevity 4.

Benefits of Using the 3970937 Turbocharger

Using the Cummins 3970937 Turbocharger offers several benefits for heavy-duty truck engines. These include improved engine efficiency, increased power output, and enhanced fuel economy. The turbocharger allows the engine to operate more effectively, resulting in better overall performance and reduced fuel consumption. Additionally, the increased power output enables the truck to handle heavier loads and operate more efficiently, contributing to improved productivity and cost savings 5.

Installation and Integration

When installing the Cummins 3970937 Turbocharger, it is important to consider compatibility with various engine models and configurations. Proper installation ensures optimal performance and longevity of the turbocharger. Guidelines for installation include ensuring a secure fit, proper alignment, and correct connection of all components. Integration with the engine’s air intake and exhaust systems is crucial for achieving the desired performance gains 6.

Performance and Efficiency

The performance and efficiency gains achieved with the Cummins 3970937 Turbocharger are significant. Real-world examples and data demonstrate improved engine performance, increased power output, and enhanced fuel economy. These gains contribute to better overall vehicle efficiency and reliability, making the turbocharger a valuable component for heavy-duty truck engines 7.

Maintenance and Troubleshooting

Maintaining and troubleshooting the Cummins 3970937 Turbocharger involves several practical considerations. Regular maintenance practices include inspecting for leaks, ensuring proper lubrication, and monitoring for signs of wear or damage. Common issues may include turbine imbalance, bearing failure, or compressor fouling. Diagnostic procedures involve checking for proper operation, measuring boost pressure, and inspecting for physical damage. Recommended maintenance practices help ensure optimal performance and longevity of the turbocharger 8.

Cummins Corporation

Cummins Corporation is a renowned manufacturer with a long-standing reputation in the industry for producing high-quality automotive components. The company’s history is marked by a commitment to innovation and quality, which is reflected in its product offerings. Cummins’ dedication to advancing technology and improving engine performance has established it as a leader in the production of turbochargers and other automotive components.

Cummins Turbocharger 3970937 Compatibility

The Cummins turbocharger part number 3970937 is designed to enhance the performance of various engine models by increasing the air intake, thereby improving efficiency and power output. This turbocharger is compatible with several engine configurations, ensuring optimal performance across different applications.

Engine Compatibility

-

4B3.9 Series

- The 3970937 turbocharger is specifically engineered to fit seamlessly with the 4B3.9 engine series. This compatibility ensures that the turbocharger can effectively manage the air intake requirements of the 4B3.9 engines, providing a significant boost in performance and efficiency.

-

Other Cummins Engines

- While the primary focus is on the 4B3.9 series, the 3970937 turbocharger is also designed to be compatible with other Cummins engine models. This versatility allows for broader application across various engine types, ensuring that the turbocharger can be utilized in multiple configurations without compromising performance.

Installation and Performance

-

Seamless Integration

- The installation of the 3970937 turbocharger in compatible engines is designed to be straightforward, ensuring that the turbocharger integrates seamlessly with the engine’s existing components. This ease of installation minimizes downtime and maximizes the benefits of the turbocharger.

-

Enhanced Efficiency

- By improving the air intake, the 3970937 turbocharger significantly enhances the engine’s efficiency. This improvement is particularly noticeable in high-performance applications where increased power output and efficiency are critical.

-

Reliability and Durability

- Built with high-quality materials and advanced engineering, the 3970937 turbocharger is designed to withstand the rigors of heavy-duty use. This reliability ensures that the turbocharger can deliver consistent performance over an extended period, making it a valuable component for various engine applications.

Role of Part 3970937 Turbocharger in Engine Systems

The integration of part 3970937, a turbocharger, into engine systems significantly enhances performance and efficiency. This component works in tandem with several key engine components to optimize the combustion process and increase power output.

Air Intake System

The turbocharger is positioned after the air intake system. As air enters the engine, the turbocharger compresses it, increasing its density. This denser air allows for more fuel to be combusted in each cycle, leading to enhanced power and efficiency.

Exhaust System

Connected to the exhaust manifold, the turbocharger harnesses the energy from the exhaust gases. These gases spin the turbine within the turbocharger, which in turn drives the compressor. This process creates a continuous loop, where exhaust energy is recycled to improve air intake.

Intercooler

In many setups, the compressed air from the turbocharger passes through an intercooler before entering the engine. The intercooler reduces the temperature of the compressed air, increasing its density further and preventing detonation.

Fuel Injection System

The turbocharger’s ability to deliver a higher volume of air into the combustion chamber necessitates a corresponding increase in fuel delivery. The fuel injection system must be calibrated to match the increased air volume, ensuring a proper air-fuel ratio for optimal combustion.

Engine Control Unit (ECU)

The ECU plays a vital role in managing the turbocharger’s operation. It monitors various parameters such as boost pressure, air temperature, and engine load. Based on these inputs, the ECU adjusts the turbocharger’s performance to maintain efficient and safe operation.

Piston and Cylinder Assembly

The increased air and fuel mixture delivered by the turbocharger results in higher combustion pressures. The piston and cylinder assembly must be designed to withstand these pressures, ensuring durability and reliability under boosted conditions.

Wastegate

To prevent over-boosting, a wastegate is often employed. This valve diverts excess exhaust gases around the turbocharger, regulating the boost pressure and protecting the engine from damage.

Charge Air Cooler (CAC)

Similar to the intercooler, the CAC cools the compressed air before it enters the engine. This cooling process increases air density, allowing for more efficient combustion and improved engine performance.

By understanding how part 3970937 turbocharger interacts with these components, engineers and mechanics can better optimize engine systems for enhanced performance and efficiency.

Conclusion

The Cummins 3970937 Turbocharger is a critical component in the enhancement of heavy-duty truck engine performance and efficiency. Its role in increasing air intake, improving fuel economy, and boosting power output makes it an invaluable part of modern engine systems. Proper installation, maintenance, and understanding of its interaction with other engine components are essential for maximizing the benefits of this turbocharger. Cummins Corporation’s commitment to quality and innovation ensures that the 3970937 turbocharger remains a reliable and efficient solution for heavy-duty applications.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Cummins Corporation. (n.d.). General Information, Bulletin Number 4021618, Owners Manual.

↩ -

Cummins Corporation. (n.d.). General Information, Bulletin Number 4021618, Owners Manual.

↩ -

Cummins Corporation. (n.d.). General Information, Bulletin Number 4021618, Owners Manual.

↩ -

Cummins Corporation. (n.d.). General Information, Bulletin Number 4021618, Owners Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.