This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

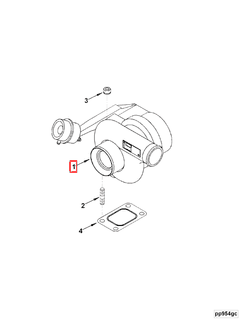

The Cummins 3967635 Turbocharger is designed to enhance the performance of commercial trucks by increasing engine efficiency and power output. This part is part of Cummins Inc.’s lineup of aftermarket parts, recognized for their reliability and performance in the commercial trucking industry.

Basic Concepts of Turbocharging

Turbocharging increases an engine’s power output by forcing extra air into the combustion chamber. This turbocharger consists of a turbine and a compressor connected by a shaft. Exhaust gases spin the turbine, and the compressor draws in and compresses air, which is then fed into the engine. This results in more fuel being burned per cycle, leading to increased power and efficiency 1.

Purpose of the Cummins 3967635 Turbocharger

The Cummins 3967635 Turbocharger is designed to improve engine efficiency and power output in commercial trucks. By compressing the intake air, it allows for more fuel to be burned, which translates to greater torque and horsepower. This enhancement is particularly beneficial for trucks that require robust performance under heavy loads or in challenging driving conditions 2.

Key Features

The Cummins 3967635 Turbocharger features a robust design that includes high-quality materials and advanced technology. Its construction ensures durability under the stress of heavy-duty use, while technological advancements such as improved compressor and turbine designs contribute to its efficiency and performance. These features make it a reliable choice for enhancing truck engine capabilities.

Benefits of Using the Cummins 3967635 Turbocharger

Installing the Cummins 3967635 Turbocharger in commercial trucks offers several advantages. It provides improved fuel efficiency by optimizing the air-fuel mixture, leading to cost savings over time. Additionally, the increased power output enhances the truck’s performance, allowing it to handle heavier loads more effectively. The turbocharger’s durable construction also contributes to its longevity, reducing the need for frequent replacements 3.

Installation and Integration

Proper installation of the Cummins 3967635 Turbocharger is crucial for ensuring it functions correctly within the truck’s engine system. This process may require specific modifications or considerations, such as ensuring compatibility with the engine’s existing components and adjusting the engine control unit (ECU) settings to optimize performance. Following manufacturer guidelines during installation helps maintain the turbocharger’s efficiency and durability.

Performance Enhancements

The Cummins 3967635 Turbocharger contributes to overall truck performance by increasing torque, horsepower, and drivability. These enhancements allow the truck to operate more efficiently under various conditions, from hauling heavy loads to navigating challenging terrains. The improved performance also translates to better fuel economy, making it a valuable addition for commercial truck operators.

Troubleshooting Common Issues

Turbochargers, including the Cummins 3967635 model, may encounter issues such as oil leaks, compressor fouling, or turbine damage. Troubleshooting these problems involves diagnostic procedures to identify the root cause, followed by appropriate solutions such as cleaning, repairing, or replacing damaged components. Regular maintenance and inspections can help prevent many of these issues.

Maintenance Tips

To ensure the Cummins 3967635 Turbocharger operates at optimal performance and longevity, regular maintenance is recommended. This includes inspecting for signs of wear or damage, cleaning the compressor and turbine to remove any buildup, and replacing worn components as necessary. Adhering to manufacturer-recommended maintenance schedules helps maintain the turbocharger’s efficiency and reliability.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial truck, bus, construction, agricultural, and power generation markets. The company’s reputation for reliability and performance makes its products, including the 3967635 Turbocharger, a preferred choice in the industry.

Compatibility

The Cummins turbocharger part number 3967635 is engineered to seamlessly integrate with a variety of engine models, ensuring optimal performance and efficiency. This turbocharger is designed to work with the following engines:

- 4B3.9: The turbocharger 3967635 is specifically tailored to fit the 4B3.9 engine, enhancing its power output and fuel efficiency. Its robust design ensures durability and reliability, making it a preferred choice for heavy-duty applications.

Grouping of Compatible Engines

The turbocharger 3967635 is part of a broader range of components designed to work with multiple Cummins engine models. While the 4B3.9 is a notable example, this turbocharger is also compatible with other engines within the Cummins lineup, providing a versatile solution for various applications.

Integration and Performance

When installed in the 4B3.9 engine, the turbocharger 3967635 improves the engine’s air intake, allowing for better combustion and increased horsepower. Its integration is straightforward, designed to fit seamlessly into the engine’s architecture without requiring significant modifications. This ease of installation ensures that users can quickly reap the benefits of enhanced performance and efficiency.

Understanding the Integration of Part 3967635 Turbocharger in Engine Systems

The turbocharger, specifically part 3967635, is a pivotal component in enhancing the performance of engine systems. Its primary role is to increase the efficiency and power output of the engine by compressing the intake air before it enters the combustion chamber. This process allows for more fuel to be burned, resulting in increased power without a corresponding increase in engine size.

Air Intake System

When integrated with the air intake system, the turbocharger works in tandem with the air filter, intake manifold, and intercooler. The compressed air from the turbocharger is cooled by the intercooler before it is directed into the intake manifold. This cooled, dense air mixes with fuel in the combustion chamber, leading to more efficient combustion and increased power output.

Exhaust System

On the exhaust side, the turbocharger is connected to the exhaust manifold. As exhaust gases exit the engine, they spin the turbine within the turbocharger. This spinning action drives the compressor side of the turbocharger, creating a continuous cycle of compressed air intake and exhaust gas expulsion. The efficiency of this system is enhanced by the design of the exhaust manifold and the smoothness of the exhaust flow, which minimizes backpressure and maximizes turbine spin.

Fuel System

The turbocharger’s role extends to the fuel system as well. With the increased air density provided by the turbocharger, the fuel injectors are able to deliver a greater amount of fuel into the combustion chamber. This precise fuel delivery is managed by the engine control unit (ECU), which monitors various parameters to ensure optimal air-fuel ratio for peak performance and efficiency.

Engine Control Unit (ECU)

The ECU plays a significant role in managing the turbocharger’s operation. It monitors sensors such as the boost pressure sensor, air temperature sensor, and oxygen sensor to adjust the fuel injection timing and quantity. This ensures that the engine operates within safe parameters, preventing issues such as detonation or overheating.

Cooling System

The integration of the turbocharger also impacts the engine’s cooling system. The increased power output and higher operating temperatures necessitate a robust cooling system. The radiator, water pump, and thermostat work in concert to maintain optimal engine temperature, ensuring the turbocharger and other components operate efficiently.

Lubrication System

Lastly, the turbocharger relies on the engine’s lubrication system to function smoothly. Adequate oil flow is essential to lubricate the turbocharger’s bearings and reduce friction. The oil filter and oil pump must be in top condition to ensure clean and consistent oil supply to the turbocharger.

Conclusion

The Cummins 3967635 Turbocharger is intricately connected with various engine components, enhancing overall performance and efficiency. Its integration requires a harmonious operation of the air intake, exhaust, fuel, ECU, cooling, and lubrication systems to achieve optimal engine performance.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Smil, V. (2010). The History and Impact of Diesel Engines and Gas Turbines. The MIT Press.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.