This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3966674 Turbocharger is designed to enhance the performance of commercial trucks by increasing engine efficiency and power output. This turbocharger forces additional air into the combustion chamber, optimizing engine performance, improving fuel efficiency, and ensuring reliable operation under various driving conditions 3.

Basic Concepts of Turbochargers

A turbocharger increases an internal combustion engine’s efficiency and power output by forcing extra air into the combustion chamber, a process known as forced induction. This allows more fuel to be burned, resulting in increased power. A turbocharger consists of two main components: a turbine and a compressor. The turbine, driven by the engine’s exhaust gases, spins a compressor that draws in air, compresses it, and sends it into the engine 2.

Purpose of the Cummins 3966674 Turbocharger

The Cummins 3966674 Turbocharger enhances engine efficiency and power output by compressing the air entering the engine, allowing for more fuel to be burned in each combustion cycle. This results in increased horsepower and torque, which are essential for the performance of commercial trucks, especially under heavy loads or in challenging driving conditions 3.

Key Features

The Cummins 3966674 Turbocharger is characterized by its robust design and the use of high-quality materials. It incorporates technological advancements such as precision machining and advanced materials to ensure durability and efficiency. Unique characteristics of this turbocharger include its compact design, which allows for easier installation and integration with various engine types, and its ability to operate efficiently across a wide range of engine speeds 1.

Benefits

Using the Cummins 3966674 Turbocharger offers several benefits, including increased horsepower, improved fuel efficiency, and enhanced durability. These benefits contribute to overall truck performance by providing more power for hauling heavy loads and improving fuel economy, which can lead to lower operational costs. The turbocharger’s durable construction ensures long-term reliability, reducing the need for frequent replacements 3.

Installation and Compatibility

Proper installation of the Cummins 3966674 Turbocharger is essential for ensuring optimal performance and longevity. It is designed to be compatible with a variety of truck models and engine types, making it a versatile choice for fleet operators. Following the manufacturer’s guidelines for installation ensures that the turbocharger operates efficiently and effectively within the engine system 3.

Performance and Efficiency

The performance metrics and efficiency gains associated with the Cummins 3966674 Turbocharger are notable when compared to non-turbocharged engines and other turbocharger models. It provides significant increases in horsepower and torque, leading to improved acceleration and towing capabilities. Additionally, the turbocharger enhances fuel efficiency by allowing the engine to burn fuel more completely, resulting in lower emissions and reduced fuel consumption 3.

Troubleshooting and Maintenance

Common issues associated with the Cummins 3966674 Turbocharger may include oil leaks, turbine imbalance, or compressor fouling. Troubleshooting steps involve inspecting for leaks, checking the turbine for damage, and cleaning or replacing the compressor if necessary. Regular maintenance, such as oil changes and filter replacements, is crucial for ensuring longevity and optimal performance. Inspection intervals and replacement guidelines should be followed according to the manufacturer’s recommendations 3.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the automotive industry. The company is committed to advancing technology and improving the efficiency and reliability of its products, including turbochargers and other engine components 3.

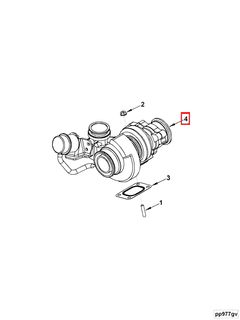

Turbocharger 3966674 in ISBE CM800 Engines

The Turbocharger 3966674, manufactured by Cummins, is a critical component in the ISBE CM800 engine series. This turbocharger is designed to enhance the engine’s performance by increasing the air intake, which allows for more efficient combustion and greater power output.

In the context of the ISBE CM800 engines, the turbocharger plays a pivotal role in maintaining optimal performance levels, especially in high-demand applications. The integration of this turbocharger ensures that the engine can handle increased loads without compromising on efficiency or reliability.

The design and engineering of the 3966674 turbocharger are tailored to fit seamlessly within the ISBE CM800 engine architecture, ensuring compatibility and ease of installation. This turbocharger is engineered to withstand the rigors of continuous operation, providing durability and longevity in demanding environments.

The use of the 3966674 turbocharger in the ISBE CM800 engines is a testament to Cummins’ commitment to delivering high-quality, reliable components that enhance engine performance. This turbocharger is a key element in the overall efficiency and power capabilities of the ISBE CM800 engine series 3.

Role of the 3966674 Turbocharger in Engine Systems

The 3966674 turbocharger is a pivotal component in enhancing the performance of engine systems. When integrated into an engine, it works in conjunction with several key components to optimize the overall efficiency and power output.

Integration with the Intake System

The turbocharger is positioned between the engine’s intake manifold and the air filter. Its primary function is to compress the incoming air, which is then fed into the combustion chambers. This increased air density allows for more fuel to be burned, resulting in enhanced power output 2.

Interaction with the Exhaust System

Exhaust gases drive the turbocharger’s turbine. As the exhaust flows through the turbine housing, it spins the turbine wheel. This rotational energy is transferred via a shaft to the compressor wheel, creating a cycle that continually forces more air into the engine 2.

Coordination with the Fuel Injection System

With the turbocharger providing denser air, the fuel injection system must adapt to maintain the correct air-fuel ratio. Modern engines equipped with electronic control units (ECUs) adjust fuel delivery in real-time to match the increased air volume, ensuring optimal combustion efficiency 2.

Synergy with the Intercooler

Many turbocharged engines incorporate an intercooler to cool the compressed air before it enters the combustion chamber. The turbocharger works in tandem with the intercooler to reduce air temperature, which increases air density even further and prevents detonation 2.

Impact on the Engine Control Unit (ECU)

The ECU plays a significant role in managing the turbocharger’s operation. Sensors monitor various parameters such as boost pressure, air temperature, and engine speed. The ECU uses this data to control the wastegate, which regulates the amount of exhaust gas flowing through the turbine, thereby controlling boost levels 2.

Influence on the Piston and Cylinder Assembly

The increased air and fuel mixture resulting from the turbocharger’s operation places greater demands on the piston and cylinder assembly. These components must be designed to withstand higher pressures and temperatures, ensuring durability and reliability under boosted conditions 1.

Effect on the Exhaust Gas Recirculation (EGR) System

The EGR system recirculates a portion of the exhaust gas back into the intake tract to reduce nitrogen oxides (NOx) emissions. The turbocharger affects the EGR system by altering the pressure dynamics within the engine, requiring careful calibration to maintain emission standards while maximizing performance 2.

Conclusion

The Cummins 3966674 Turbocharger is a critical component in enhancing the performance, efficiency, and power output of commercial truck engines. Its integration with various engine systems ensures optimal performance under demanding conditions, contributing to improved fuel efficiency, increased power, and reliable operation. Regular maintenance and proper installation are essential for maximizing the benefits of this turbocharger 3.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ ↩ -

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.