This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

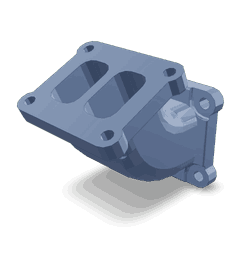

The Turbocharger Exhaust Inlet Connection, identified by Part #3899235, is a component manufactured by Cummins, a leading name in the commercial truck industry. This part plays a significant role in the turbocharger system, contributing to the overall performance and efficiency of heavy-duty trucks. Understanding its function and integration within the engine system is vital for maintaining and optimizing truck performance 1.

Basic Concepts of Turbocharger Exhaust Inlet Connection

Turbochargers operate on the principle of using exhaust gases to drive a turbine, which in turn compresses the intake air before it enters the engine. This process increases the density of the air entering the engine, allowing for more fuel to be burned and thus enhancing engine power and efficiency. The exhaust inlet connection is a critical component in this system, as it directs the exhaust gases from the engine to the turbocharger turbine. Its design and construction are engineered to ensure efficient transfer of exhaust gases, minimizing energy loss and maximizing turbocharger performance 2.

Purpose and Function

The Turbocharger Exhaust Inlet Connection serves to interface the exhaust system with the turbocharger, facilitating the flow of exhaust gases that drive the turbine. By optimizing the path and pressure of these gases, the connection enhances the turbocharger’s efficiency, leading to improved engine performance. It is designed to withstand high temperatures and pressures, ensuring reliable operation under various driving conditions 3.

Key Features

The Turbocharger Exhaust Inlet Connection is characterized by several key features that contribute to its performance and durability. These include its material composition, typically made from high-strength alloys to resist corrosion and thermal stress, and its precise engineering specifications that ensure a secure and efficient connection between the exhaust system and the turbocharger. The design elements, such as the shape and size of the inlet, are optimized to enhance the flow of exhaust gases, further improving turbocharger efficiency.

Benefits

Incorporating the Turbocharger Exhaust Inlet Connection into a truck’s engine system offers several benefits. It contributes to increased engine power by enhancing the efficiency of the turbocharger. This results in improved fuel efficiency, as the engine can burn more fuel with the increased air density provided by the turbocharger. Additionally, the overall performance of the truck is enhanced, offering better acceleration and higher top speeds, which are crucial for commercial truck operations.

Installation and Integration

Proper installation of the Turbocharger Exhaust Inlet Connection is crucial for ensuring optimal performance. It involves securing the connection between the exhaust manifold and the turbocharger, ensuring a leak-free seal. Careful attention must be paid to the alignment and torque specifications to prevent damage and ensure efficient operation. Integration with the existing exhaust and turbocharger system requires a thorough understanding of the truck’s engine configuration and the specific requirements of the turbocharger system.

Maintenance and Troubleshooting

Regular maintenance of the Turbocharger Exhaust Inlet Connection is necessary to ensure its longevity and performance. This includes inspecting for signs of wear, corrosion, or leaks, and addressing any issues promptly. Common problems may include gasket failure or blockages in the exhaust path, which can be identified through routine checks and addressed with appropriate repairs or replacements. Troubleshooting tips include verifying the connection’s integrity, ensuring proper alignment, and checking for any obstructions in the exhaust flow.

Performance Enhancements

The Turbocharger Exhaust Inlet Connection plays a role in performance enhancements in heavy-duty trucks by optimizing the turbocharger’s efficiency. Real-world applications demonstrate its effectiveness in improving engine power and fuel efficiency, contributing to the overall performance of commercial trucks. Case studies and feedback from truck operators highlight the significant impact this component can have on truck operations, particularly in demanding applications.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product range includes a variety of engines and components designed to meet the diverse needs of commercial truck operators, ensuring optimal performance and efficiency in various applications.

Turbocharger Exhaust Inlet Connection in Cummins Engines

The turbocharger exhaust inlet connection, part number 3899235, is a critical component in the Cummins M11 engine family. This part is integral to the functionality of the turbocharger system, ensuring efficient and reliable operation.

M11 CELECT PLUS and M11 MECHANICAL Engines

In the M11 CELECT PLUS and M11 MECHANICAL engines, the turbocharger exhaust inlet connection plays a pivotal role in managing the exhaust gases that drive the turbocharger. This connection is designed to withstand the high temperatures and pressures inherent in the exhaust system, ensuring durability and longevity.

The part interfaces directly with the turbocharger’s exhaust housing, creating a secure seal that prevents leaks. This seal is crucial for maintaining the efficiency of the turbocharger, as any leakage can lead to reduced performance and increased fuel consumption.

The design of the turbocharger exhaust inlet connection is optimized for both the M11 CELECT PLUS and M11 MECHANICAL engines. It is engineered to fit seamlessly into the engine’s exhaust manifold, ensuring a precise and reliable connection. This precision is essential for maintaining the balance and efficiency of the turbocharger system.

By integrating this part into the engine’s design, Cummins ensures that the turbocharger can operate at peak efficiency, contributing to the overall performance and reliability of the engine. The turbocharger exhaust inlet connection is a testament to Cummins’ commitment to quality and performance in their engine designs.

Role of Part 3899235 Turbocharger Exhaust Inlet Connection in Engine Systems

The Turbocharger Exhaust Inlet Connection is integral to the efficient operation of the turbocharger within an engine system. This component facilitates the connection between the exhaust manifold and the turbocharger, allowing exhaust gases to flow into the turbocharger’s turbine.

Integration with the Turbocharger

In the turbocharger arrangement, the Turbocharger Exhaust Inlet Connection ensures a secure and leak-free passage for exhaust gases. These gases spin the turbine, which in turn drives the compressor. The compressor increases the density of the air entering the engine, enhancing combustion efficiency and power output.

Interaction with the Exhaust Manifold

The connection component is designed to mate precisely with the exhaust manifold. This ensures that all exhaust gases are directed into the turbocharger without any loss, maximizing the energy recovery from the exhaust stream. Proper sealing at this junction is essential to prevent any exhaust gas leaks, which could reduce turbocharger efficiency and increase emissions.

Contribution to Engine Performance

By efficiently channeling exhaust gases, the Turbocharger Exhaust Inlet Connection plays a significant role in maintaining the turbocharger’s performance. It helps in achieving the desired boost pressure by ensuring that the turbine receives a consistent flow of exhaust gases. This consistent flow is vital for the turbocharger to operate within its optimal range, contributing to overall engine performance and fuel efficiency.

Role in Emission Control

Effective management of exhaust gases through the Turbocharger Exhaust Inlet Connection also aids in emission control. By ensuring that exhaust gases are fully utilized to drive the turbocharger, this component helps in reducing unburnt hydrocarbons and other pollutants that might otherwise escape into the atmosphere.

Conclusion

The Turbocharger Exhaust Inlet Connection, part number 3899235, is a key component in the turbocharger system, enhancing engine performance, ensuring efficient operation, and contributing to lower emissions. Its role in facilitating the flow of exhaust gases to the turbocharger, optimizing turbocharger efficiency, and aiding in emission control underscores its importance in the operation of heavy-duty trucks. Proper installation, maintenance, and understanding of this component are essential for maximizing the performance and reliability of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.