This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

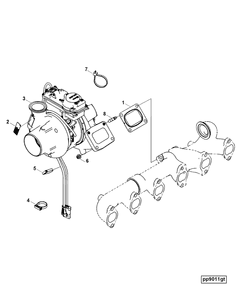

The Turbocharger Electric Actuator (Part #3787565) by Cummins is a component designed to enhance the performance of commercial trucks. Its purpose is to regulate the turbocharger’s operation, ensuring optimal engine performance under various driving conditions. This actuator is significant in the operation of commercial trucks as it contributes to improved engine efficiency and overall vehicle performance.

Basic Concepts of Turbocharger Electric Actuators

Turbocharger electric actuators operate on the principle of forced induction, where they compress the air entering the engine, allowing for more fuel to be burned and thus generating more power. These actuators use electrical signals to control the position of the turbocharger’s wastegate or variable geometry vanes. By modulating the airflow, they help maintain the desired boost pressure, which is crucial for engine performance. The electric actuator provides precise control over the turbocharger, enhancing its responsiveness and efficiency 1.

Role and Function in Truck Operation

The Turbocharger Electric Actuator plays a vital role in the operation of a truck by managing the turbocharger’s performance. It interacts with the turbocharger to adjust the airflow according to the engine’s needs. This ensures that the engine receives the optimal amount of air, which is necessary for efficient combustion. The actuator’s ability to make real-time adjustments helps maintain engine performance across different load conditions and driving scenarios 2.

Key Features

Several key features distinguish the Turbocharger Electric Actuator. Precision control allows for accurate adjustments to the turbocharger’s operation, ensuring consistent performance. Durability is another important feature, as the actuator is designed to withstand the harsh conditions of commercial truck operation. Additionally, the actuator is integrated with the engine management system, allowing for seamless communication and coordination with other engine components 3.

Benefits

The Turbocharger Electric Actuator offers several benefits. It improves engine efficiency by ensuring that the turbocharger operates at optimal levels. This leads to enhanced performance, as the engine can produce more power with the same amount of fuel. Additionally, the actuator can contribute to potential fuel savings by optimizing the air-fuel mixture and reducing unnecessary fuel consumption.

Installation and Integration

When installing the Turbocharger Electric Actuator, it is important to follow the manufacturer’s guidelines to ensure proper integration within the truck’s engine system. This includes connecting the actuator to the turbocharger and the engine management system. Careful attention to electrical connections and mounting procedures is necessary to ensure reliable operation.

Troubleshooting Common Issues

Common issues with the Turbocharger Electric Actuator may include malfunctions in the electrical system, incorrect actuator positioning, or problems with the turbocharger itself. Troubleshooting steps may involve checking electrical connections, ensuring proper actuator alignment, and inspecting the turbocharger for any signs of damage or wear. Diagnostic tools can be used to identify specific issues and guide the repair process.

Maintenance Tips

Regular maintenance practices are important to ensure the longevity and optimal performance of the Turbocharger Electric Actuator. This includes periodic inspections of electrical connections, ensuring the actuator is properly aligned, and checking for any signs of wear or damage. Keeping the turbocharger and associated components clean and free of debris can also contribute to the actuator’s reliable operation.

Performance Monitoring

Monitoring the performance of the Turbocharger Electric Actuator can be achieved through various methods. Diagnostic techniques, such as using onboard diagnostic systems, can provide real-time data on the actuator’s operation. This data can help identify any deviations from normal performance and guide maintenance or repair efforts. Regular performance checks can ensure that the actuator continues to operate efficiently.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its high-quality engines and components. With a history of innovation and a diverse product range, Cummins has built a reputation for reliability and performance. The company’s commitment to advancing technology and meeting the needs of its customers has made it a leader in the industry.

Turbocharger Electric Actuator (Part 3787565) Compatibility with Cummins Engines

The Turbocharger Electric Actuator, part number 3787565, manufactured by Cummins, is a critical component in the operation of turbochargers within various engine models. This actuator is designed to precisely control the turbocharger’s wastegate, ensuring optimal performance and efficiency across different engine configurations.

ISC8.3 CM2250 and ISL9 CM2250

The ISC8.3 CM2250 and ISL9 CM2250 engines both utilize the CM2250 platform, which is known for its robust design and high performance. The Turbocharger Electric Actuator in these engines is engineered to work seamlessly with the specific demands of the CM2250 platform, providing precise control over the turbocharger’s boost pressure. This ensures that the engines maintain peak performance under varying load conditions, enhancing both power output and fuel efficiency.

QSL9 CM2250 and QSL9 CM2350 L102

The QSL9 CM2250 and QSL9 CM2350 L102 engines also benefit from the Turbocharger Electric Actuator, part number 3787565. These engines, while sharing the QSL9 designation, incorporate different turbocharger configurations and power outputs. The actuator is designed to interface with the specific wastegate mechanisms of these engines, ensuring that the turbocharger operates within the optimal range for each model. This compatibility is crucial for maintaining the balance between power delivery and engine longevity, particularly in heavy-duty applications.

Role of Part 3787565 Turbocharger Electric Actuator in Engine Systems

The Turbocharger Electric Actuator (Part 3787565) is integral to the operation of modern turbocharged engine systems. This component is designed to enhance the performance and efficiency of the turbocharger by precisely controlling the position of the wastegate or variable geometry vanes.

Integration with Turbocharger

When integrated with a turbocharger, the electric actuator replaces traditional mechanical linkages or vacuum-operated systems. It allows for more precise and rapid adjustments to the turbocharger’s operation. This results in improved throttle response, better fuel efficiency, and reduced turbo lag.

Function within Turbocharger Actuator Kit

In a Turbocharger Actuator Kit, the electric actuator works in conjunction with sensors and an electronic control unit (ECU). The ECU monitors various parameters such as engine speed, load, and boost pressure. It then sends signals to the actuator to adjust the wastegate or vanes accordingly, ensuring optimal turbocharger performance under varying driving conditions.

Role in Turbocharger Electric Actuator Kit

A Turbocharger Electric Actuator Kit typically includes the electric actuator, wiring harness, and mounting brackets. This kit is designed for easy retrofitting into existing turbocharger systems. The electric actuator provides superior control over traditional methods, allowing for fine-tuning of boost levels and improving overall engine performance.

Contribution to Turbocharger Kit

In a comprehensive Turbocharger Kit, which may include the turbocharger, intercooler, and associated piping, the electric actuator plays a significant role in maintaining system harmony. It ensures that the turbocharger operates within its designed parameters, preventing over-boosting and potential engine damage. The precise control offered by the electric actuator also contributes to the longevity and reliability of the turbocharger system.

Enhanced System Performance

The incorporation of Part 3787565 into these systems allows for dynamic adjustment of turbocharger operation. This leads to enhanced drivability, increased power output, and improved fuel economy. The electric actuator’s ability to make real-time adjustments based on driving conditions makes it a valuable component in both stock and performance-oriented engine setups.

Conclusion

The Turbocharger Electric Actuator (Part 3787565) by Cummins is a critical component in enhancing the performance and efficiency of turbocharged engines. Its precise control over turbocharger operation ensures optimal engine performance across various driving conditions. The actuator’s integration with modern engine management systems allows for dynamic adjustments, contributing to improved throttle response, fuel efficiency, and overall engine performance. Regular maintenance and monitoring are essential to ensure the longevity and reliability of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.