This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

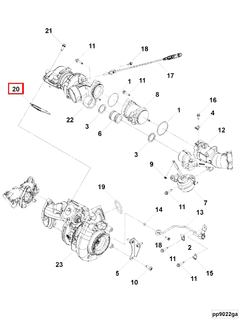

Introduction to Turbocharger Gaskets

Turbocharger gaskets are critical in the operation of turbocharged engines, especially in commercial trucks. These gaskets create a secure seal between the turbocharger and the engine, preventing leaks that could otherwise compromise performance and efficiency. The Cummins 3779725 turbocharger gasket is designed to withstand the demanding conditions of heavy-duty applications, ensuring reliable performance 1.

Basic Concepts Related to Turbocharger Gaskets

Turbocharger gaskets are made from materials that can endure high temperatures and pressures. Positioned between the turbocharger housing and the engine manifold, these gaskets form a seal that prevents exhaust gases from escaping into unintended areas. This seal is crucial for maintaining turbocharger efficiency and overall engine performance 2.

Purpose of the Cummins 3779725 Turbocharger Gasket

The Cummins 3779725 turbocharger gasket plays a pivotal role in the engine’s operation. Its main function is to maintain a tight seal, ensuring the turbocharger operates efficiently. By preventing exhaust gases from leaking into the intake manifold, this gasket helps avoid power and efficiency losses. Additionally, it supports the structural integrity of the turbocharger assembly, mitigating risks from thermal expansion and contraction 3.

Role in the Operation of a Truck

In commercial trucks, engine efficiency and reliability are critical. The turbocharger enhances engine performance by forcing more air into the combustion chamber, allowing for greater fuel burn, increased power output, and improved fuel efficiency. The Cummins 3779725 turbocharger gasket ensures this process is leak-free, maintaining the delicate balance of pressure and temperature within the engine. This balance is essential for engine longevity and performance, especially under the heavy loads typical of commercial trucking 4.

Troubleshooting and Maintenance

Regular inspection and maintenance of the turbocharger gasket are vital to prevent leaks and performance degradation. Here are some essential troubleshooting and maintenance practices:

-

Visual Inspection: Regularly examine the gasket for signs of wear, such as cracks or deformation. Address any visible damage immediately to prevent further issues.

-

Pressure Testing: Perform pressure tests to verify that the gasket maintains the required seal. Detecting leaks in the turbocharger system is often possible through this method.

-

Cleaning: Ensure the mating surfaces are clean to maintain a proper seal. Debris or contamination can compromise the gasket’s effectiveness.

-

Replacement: If the gasket shows signs of wear or fails a pressure test, replace it promptly. Using an authentic Cummins 3779725 turbocharger gasket guarantees compatibility and performance.

Cummins: A Leader in Engine Technology

Cummins is a distinguished manufacturer of engines and related components, renowned for its dedication to quality and innovation. The Cummins 3779725 turbocharger gasket exemplifies this commitment, designed to meet the rigorous demands of heavy-duty applications. Cummins’ extensive industry experience assures that their components are built to endure and perform reliably under challenging conditions 5.

Conclusion

The Cummins 3779725 turbocharger gasket is a critical component in the operation of commercial trucks. Its role in maintaining a tight seal between the turbocharger and the engine is vital for ensuring optimal performance and efficiency. By understanding the purpose and maintenance of this gasket, engineers and mechanics can ensure their vehicles operate at peak performance, reducing downtime and maintenance costs.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Viskup, R. (2020). Diesel and Gasoline Engines. IntechOpen.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Service Manual (5579750) for B4.5 CM2620 B158B engine.

↩ -

Cummins Inc. (n.d.). Service Manual (5579750) for B4.5 CM2620 B158B engine.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.