This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

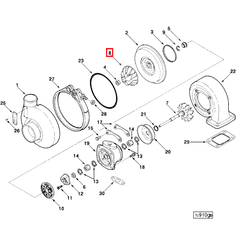

The Cummins 3599639 Turbocharger Compressor Impeller is a critical component in the turbocharger system of heavy-duty trucks. Its function is to compress the intake air before it enters the engine, thereby enhancing the engine’s performance and efficiency. This impeller is integral to the operation of the turbocharger, which significantly contributes to the overall functionality of the truck’s engine.

Basic Concepts of Turbocharger Compressor Impellers

Turbocharger compressor impellers operate on the principle of compressing intake air to increase its density. This compressed air, when mixed with fuel, allows for more efficient combustion within the engine cylinders. The impeller, a rotating component within the turbocharger, draws in ambient air and accelerates it through a series of blades. As the air passes through these blades, it is compressed and directed into the engine’s intake manifold. This process enhances engine performance by allowing more air and fuel to be burned in each combustion cycle, resulting in increased power output and improved fuel efficiency 1.

Role of the 3599639 Turbocharger Compressor Impeller in Truck Operation

The 3599639 Turbocharger Compressor Impeller specifically contributes to the operation of heavy-duty trucks by ensuring that the engine receives a consistent supply of compressed air. This component directly influences engine efficiency and power output. By compressing the intake air, the impeller allows the engine to burn more fuel per cycle, leading to enhanced performance. Additionally, the efficient operation of the impeller helps in maintaining optimal engine temperature and reducing emissions, contributing to the overall effectiveness of the truck’s powertrain 2.

Key Features of the 3599639 Turbocharger Compressor Impeller

The 3599639 Turbocharger Compressor Impeller is designed with several key features that distinguish it from other impellers. Its construction typically includes high-strength materials to withstand the high rotational speeds and pressures within the turbocharger. The impeller’s blade design is optimized for maximum air compression efficiency, ensuring that the engine receives the highest possible quality of compressed air. Additionally, the impeller is engineered to balance durability with performance, providing reliable operation under the demanding conditions experienced by heavy-duty trucks 3.

Benefits of Using the 3599639 Turbocharger Compressor Impeller

Utilizing the 3599639 Turbocharger Compressor Impeller offers several benefits. Firstly, it contributes to improved engine performance by ensuring that the engine receives a consistent and high-quality supply of compressed air. This results in increased power output and better overall engine responsiveness. Secondly, the efficient operation of the impeller can lead to increased fuel efficiency, as the engine is able to burn fuel more effectively. Lastly, the durable construction of the impeller ensures long-term reliability, reducing the need for frequent replacements and maintenance.

Troubleshooting Common Issues with Turbocharger Compressor Impellers

Common issues with turbocharger compressor impellers can include reduced efficiency, unusual noises, or decreased engine performance. These symptoms may indicate problems such as impeller wear, imbalance, or contamination. Regular inspection and maintenance can help identify these issues early. Symptoms to watch for include a decrease in engine power, unusual sounds from the turbocharger, or increased exhaust smoke. Potential causes may include impeller blade damage, bearing wear, or issues with the turbocharger’s lubrication system.

Maintenance Tips for Turbocharger Compressor Impellers

To ensure the longevity and optimal performance of turbocharger compressor impellers, regular maintenance is crucial. This includes periodic inspection for signs of wear or damage, cleaning the impeller to remove any contaminants, and ensuring that the turbocharger’s lubrication system is functioning correctly. Additionally, following the manufacturer’s guidelines for replacement intervals can help prevent unexpected failures. Regular maintenance not only enhances the performance of the impeller but also contributes to the overall reliability of the truck’s engine.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industries. The company offers a wide range of products, including diesel and natural gas engines, as well as related technologies such as turbochargers and aftertreatment systems. Cummins is known for its commitment to innovation, quality, and customer satisfaction, making it a trusted name in the industry.

Turbocharger Compressor Impeller Compatibility with Cummins Engines

The turbocharger compressor impeller part number 3599639, manufactured by Cummins, is designed to fit seamlessly with several engine models. This part is integral to the turbocharger system, enhancing the engine’s performance by increasing the air intake, which in turn boosts power output and efficiency.

Cummins Engines Compatible with Part 3599639

- 6B5.9 Engine

- G5.9 Engine

These engines are part of Cummins’ lineup, known for their robust performance and reliability in various applications. The turbocharger compressor impeller is engineered to work with these engines, ensuring optimal performance and longevity.

The compatibility of the turbocharger compressor impeller with the 6B5.9 and G5.9 engines is due to the design and specifications that align with the requirements of these engines. This ensures that the impeller can efficiently handle the airflow and pressure demands of these engines, contributing to their overall efficiency and power output.

Role of Part 3599639 Turbocharger Compressor Impeller in Engine Systems

The Part 3599639 Turbocharger Compressor Impeller is a vital component within various engine systems, particularly those utilizing aftermarket turbochargers and core assemblies. Its primary function is to compress the intake air, which is then forced into the engine’s combustion chamber. This process enhances the engine’s efficiency and power output.

Integration with Aftermarket Turbochargers

When installed in an aftermarket turbocharger, the compressor impeller works in tandem with the turbine to drive the overall performance of the turbocharger. The impeller’s design allows it to spin at high speeds, drawing in and compressing air before it is delivered to the engine. This increased air volume supports higher fuel combustion, leading to improved engine performance.

Function within Core Assemblies

In core assemblies, such as the Core Assembly H1C and Core Assembly H1E, the compressor impeller is a fundamental element. It is housed within the turbocharger core, where it interacts with other components like the H1E Rotor Assembly and the Rotor Assembly. The impeller’s efficient air compression capabilities are essential for maintaining the balance and performance of these assemblies.

Role in Turbocharger Core and Turbocharger Kit

For the turbocharger core and turbocharger kit, the compressor impeller ensures that the system operates smoothly. It is responsible for the initial stage of air compression, which sets the stage for the subsequent stages of turbocharging. The impeller’s performance directly influences the overall effectiveness of the turbocharger core and kit, making it a key component in these systems.

Conclusion

In summary, the Part 3599639 Turbocharger Compressor Impeller plays a significant role in enhancing the performance of various engine systems by efficiently compressing intake air, thereby supporting higher engine efficiency and power output.

-

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Asef, P., Padmanaban, S., & Lapthorn, A. (2022). Modern Automotive Electrical Systems. Wiley.

↩ -

Kershaw, J.F. (2023). SAE International’s Dictionary for Automotive Engineers. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.