This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Turbocharger Compressor Impeller 3593686, manufactured by Cummins, is designed for heavy-duty truck engines. This part enhances engine performance by improving air intake efficiency. Understanding its function within the engine system is essential for maximizing its benefits.

Basic Concepts of Turbocharger Compressor Impellers

Turbocharger compressor impellers compress incoming air before it enters the engine’s combustion chamber, increasing air density and allowing more oxygen for combustion. The impeller, a rotating component, accelerates the air, creating a high-pressure flow that enhances engine performance. The efficiency of this process depends on the impeller’s design and material 1.

Purpose and Role in Truck Operation

The 3593686 Turbocharger Compressor Impeller is designed for heavy-duty truck engines, contributing to increased air intake and more efficient combustion. This results in improved engine efficiency and power output. The impeller’s design allows it to operate effectively under high-stress conditions typical of heavy-duty truck engines 2.

Key Features

The 3593686 Turbocharger Compressor Impeller features a robust design and high-quality materials for durability and efficiency. Its unique blade geometry is optimized for maximum airflow and efficiency. The impeller’s construction includes features that reduce wear and improve longevity, making it reliable for heavy-duty applications.

Benefits

Incorporating the 3593686 Turbocharger Compressor Impeller offers improved engine performance, increased fuel efficiency, and enhanced durability. These benefits contribute to the overall effectiveness and reliability of the engine.

Installation and Integration

Installing the 3593686 Turbocharger Compressor Impeller requires ensuring compatibility with the specific engine model and integrating it with the existing turbocharger system. Proper installation involves attention to detail to ensure the impeller is securely fitted and operates within the designed parameters. This process may vary slightly depending on the engine model, highlighting the importance of following manufacturer guidelines.

Troubleshooting Common Issues

Common issues with turbocharger compressor impellers include reduced efficiency due to wear or damage and imbalance caused by uneven wear. Diagnostic procedures may involve inspecting the impeller for signs of wear, measuring the balance, and checking for proper installation. Solutions can range from cleaning and rebalancing the impeller to replacement in cases of significant damage.

Maintenance Practices

Maintaining the 3593686 Turbocharger Compressor Impeller involves regular inspection for signs of wear or damage, cleaning to remove contaminants, and following replacement guidelines to ensure optimal performance and longevity. Adhering to recommended maintenance routines helps prevent issues and ensures the impeller continues to operate efficiently.

Performance Enhancements

The 3593686 Turbocharger Compressor Impeller enhances overall engine performance by improving power output and torque through better air intake and combustion efficiency. These enhancements are particularly beneficial in heavy-duty truck applications, where maximizing engine performance and efficiency is crucial.

Cummins: A Brief Overview

Cummins Inc. is a leader in diesel engine technology, with a history of innovation and expertise in the automotive industry. The company’s commitment to developing reliable and efficient engine components, like the 3593686 Turbocharger Compressor Impeller, underscores its dedication to advancing diesel engine technology and meeting customer needs.

Turbocharger Compressor Impeller Compatibility with Cummins Engines

The turbocharger compressor impeller part number 3593686 is designed to fit seamlessly with various Cummins engines, ensuring optimal performance and efficiency. Below is a detailed overview of its compatibility with specific engine models:

G-Series Engines

- G855

- G855 CM558

- GTA855 CM558 (CM2358)

I-Series Engines

- ISG12 CM2880 G107

- ISM CM570

- ISX CM870

L-Series Engines

- L9.5 L117

M-Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

QSM-Series Engines

- QSM11 CM570

- QSM11 CM876

Role of Part 3593686 Turbocharger Compressor Impeller in Engine Systems

The Turbocharger Compressor Impeller, identified by part number 3593686, enhances the performance and efficiency of various engine systems by compressing intake air before it enters the combustion chamber. This increases air density, allowing for more fuel to be burned, resulting in greater power output.

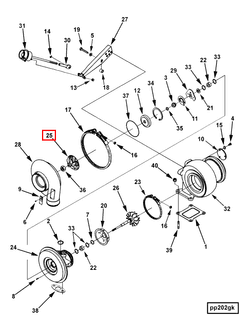

Integration with Turbocharger Systems

When installed in an aftermarket turbocharger, the impeller works with the turbine to drive the compressor wheel. The energy from the exhaust gases spins the turbine, which is connected to the impeller via a shaft. This mechanical linkage ensures that as the turbine accelerates, the impeller also spins at high speeds, compressing the intake air efficiently.

Interaction with Engine Components

- Camshaft and Valvetrain: The increased air pressure from the impeller allows the camshaft to open the intake valves wider, drawing in a larger volume of compressed air. This air, mixed with fuel, combusts more effectively, leading to improved engine performance.

- Connecting Rod and Crosshead: The enhanced combustion process results in higher pressure within the combustion chamber. This increased pressure exerts a greater force on the piston, which is transferred through the connecting rod to the crankshaft. The crosshead, in engines that utilize it, ensures smooth and efficient transmission of this force.

- Core Assembly and Heat Exchangers: The impeller’s role in compressing air also impacts the core assembly and associated heat exchangers. Efficient air compression helps maintain optimal temperatures within these components, ensuring they operate within their designed parameters.

- Turbocharger Core and Kit: Within the turbocharger core, the impeller is a fundamental element. It is part of the turbocharger kit, which includes various performance parts designed to work cohesively. The impeller’s performance directly influences the overall effectiveness of the turbocharger core, affecting boost levels and response times.

Performance Enhancement

The impeller’s ability to compress air effectively is a key factor in the performance gains observed in engines equipped with turbochargers. Whether in stock form or as part of a turbocharger kit with performance parts, the impeller ensures that the engine receives a consistent supply of high-pressure air, leading to improved throttle response, increased power output, and better fuel efficiency.

Conclusion

The Turbocharger Compressor Impeller (part 3593686) is integral to the functioning of turbocharged engine systems. Its role in compressing intake air not only enhances engine performance but also ensures the efficient operation of interconnected components such as the camshaft, connecting rod, core assembly, and various heat exchangers.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.