This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

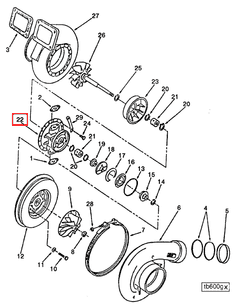

The Turbocharger Bearing Housing, specifically Part #3536903 by Cummins, is a vital component within the turbocharger system. This housing is designed to support the turbocharger’s rotating assembly, ensuring smooth operation and efficiency. Cummins, a renowned manufacturer in the automotive and heavy-duty truck industry, produces this part with a focus on durability, performance, and reliability 1.

Basic Concepts of Turbocharger Bearing Housing

Turbocharger bearing housings are integral to the functionality of turbochargers. They house the bearings that allow the turbocharger’s turbine and compressor wheels to spin at high speeds. This rotation is crucial for compressing the air entering the engine, which in turn enhances combustion efficiency and power output. The bearing housing must be robust and precisely engineered to withstand the high speeds and temperatures involved in turbocharger operation 2.

Purpose of the 3536903 Turbocharger Bearing Housing

This Cummins part plays a significant role in the operation of a truck’s engine. It supports the turbocharger’s rotating assembly, ensuring that the turbine and compressor wheels operate smoothly and efficiently. By maintaining proper alignment and reducing friction, this housing contributes to the overall performance and reliability of the turbocharger, thereby enhancing engine efficiency and power output 3.

Key Features

The 3536903 is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that can withstand the extreme conditions within a turbocharger. The design includes precision-machined surfaces to ensure optimal bearing alignment and minimal friction. Additionally, the housing may incorporate advanced cooling channels to manage heat more effectively, further contributing to its longevity and performance.

Benefits

The advantages of using the 3536903 include improved engine efficiency, enhanced durability, and potential performance gains. By ensuring smooth operation of the turbocharger’s rotating assembly, this housing helps maintain consistent engine performance under various operating conditions. Its robust construction and precise engineering contribute to longer component life and reduced maintenance requirements.

Troubleshooting and Maintenance

Common issues with this part may include bearing wear, misalignment, or heat-related damage. Regular inspection and maintenance are recommended to identify and address these issues promptly. This may involve checking for proper alignment, ensuring adequate lubrication, and monitoring operating temperatures. Following manufacturer guidelines for maintenance can help ensure optimal performance and longevity of the turbocharger bearing housing.

Installation Considerations

When installing the 3536903, it is important to consider compatibility with other components, proper alignment, and adherence to torque specifications. Ensuring that the housing is correctly aligned with the turbocharger’s rotating assembly and securely fastened according to manufacturer guidelines will help maintain efficient operation and prevent potential issues.

Performance Impact

The 3536903 affects overall engine performance by supporting the efficient operation of the turbocharger. This can lead to changes in power output, fuel efficiency, and emissions. A well-maintained and properly functioning bearing housing contributes to smoother turbocharger operation, which in turn can enhance engine performance and efficiency.

Cummins Overview

Cummins is a well-established manufacturer with a strong reputation in the automotive and heavy-duty truck industry. The company is known for its commitment to quality, innovation, and customer satisfaction. Cummins’ extensive experience and dedication to engineering excellence are reflected in their turbocharger components, including the 3536903.

Turbocharger Bearing Housing for Cummins Engines

The Turbocharger Bearing Housing, part number 3536903, is a critical component in the turbocharger system of several Cummins engines. This part ensures the smooth operation of the turbocharger by providing a stable and secure mounting for the bearings that support the turbine and compressor wheels.

K50 Engines

In the K50 series engines, the turbocharger bearing housing is integral to maintaining the efficiency of the turbocharger. The housing must be precisely manufactured to fit the specific design and operational parameters of the K50 engine. Its role is to house the bearings that allow the turbine and compressor wheels to rotate freely while withstanding high-speed operation and thermal stresses.

QSK19 and CM500 Engines

For the QSK19 and CM500 engines, the turbocharger bearing housing is equally vital. These engines are designed for heavy-duty applications, and the turbocharger bearing housing must be robust enough to handle the increased power output and operational demands. The housing in these engines is engineered to provide optimal support and longevity, ensuring that the turbocharger operates efficiently under various load conditions.

The turbocharger bearing housing in the QSK19 and CM500 engines is designed to integrate seamlessly with the engine’s turbocharger system. It must be compatible with the specific turbocharger model used in these engines, ensuring a proper fit and function. The housing’s design also takes into account the need for easy maintenance and replacement, which is crucial for the longevity and reliability of these high-performance engines.

Integration of Part 3536903 Turbocharger Bearing Housing in Engine Systems

The Turbocharger Bearing Housing, identified by part number 3536903, is an integral component in the assembly and operation of various engine systems, particularly those involving aftermarket turbochargers and performance enhancements.

When integrating this bearing housing into an aftermarket turbocharger, it serves as the foundational structure that supports the turbocharger’s rotating assembly. This includes the turbine wheel, compressor wheel, and the shaft that connects them. The bearing housing ensures these components are aligned and operate smoothly, reducing friction and wear.

In conjunction with the Core Assembly Heat Exchanger, the bearing housing plays a supportive role. The heat exchanger is responsible for managing the temperature of the intake air after it has been compressed by the turbocharger. Efficient operation of the heat exchanger relies on the stable and precise rotation of the turbocharger components, which is facilitated by the bearing housing.

For performance parts and turbocharger kits, the bearing housing is essential for maintaining the integrity and efficiency of the turbocharger. It allows for the high-speed rotation necessary for increased air intake and, consequently, enhanced engine performance. The precision engineering of the bearing housing ensures that the turbocharger can withstand the high stresses and temperatures associated with performance driving.

Conclusion

In summary, the Turbocharger Bearing Housing (part 3536903) is a key component in the effective operation of turbochargers within engine systems. Its role in supporting and aligning the rotating assembly is fundamental to the performance and durability of the turbocharger, especially in high-performance and aftermarket applications.

-

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.