This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

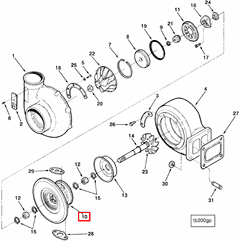

The Turbocharger Bearing Housing, specifically Part #3525199 by Cummins, is a component integral to the turbocharger system. Cummins, a renowned manufacturer in the automotive and heavy-duty truck industries, produces this bearing housing. It is designed to enhance the performance and efficiency of turbochargers, which are vital for improving engine power and fuel efficiency 1.

Basic Concepts of Turbocharger Bearing Housing

Turbochargers operate on the principle of compressing the air entering the engine, which allows for more fuel to be burned and thus generates more power. The bearing housing plays a specific role within this system by providing a stable and secure environment for the turbocharger’s rotating components. It ensures that these components can spin at high speeds with minimal friction and wear, which is essential for the efficient operation of the turbocharger 2.

Purpose and Function of the 3525199 Turbocharger Bearing Housing

The 3525199 Turbocharger Bearing Housing supports the turbocharger’s rotating components, including the turbine and compressor wheels. By housing the bearings that allow these wheels to spin, it plays a role in maintaining the turbocharger’s balance and alignment. This support is vital for the turbocharger to function correctly, ensuring that air is compressed efficiently before entering the engine 3.

Key Features

The 3525199 Turbocharger Bearing Housing is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that can withstand the high temperatures and pressures within the turbocharger system. Its design includes precision-machined surfaces to ensure a perfect fit with other turbocharger components, and it may incorporate advanced lubrication systems to reduce friction and wear on the bearings.

Benefits of Using the 3525199 Turbocharger Bearing Housing

Utilizing the 3525199 Turbocharger Bearing Housing offers several advantages. It contributes to improved engine efficiency by ensuring the turbocharger operates smoothly and effectively. Its durable construction and advanced features enhance the turbocharger’s longevity, reducing the need for frequent replacements. Additionally, by supporting optimal turbocharger performance, it can lead to increases in power output and overall engine reliability.

Installation and Integration

Proper installation of the 3525199 Turbocharger Bearing Housing is crucial for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines, which may include specific preparations such as cleaning the turbocharger and inspecting other components for wear or damage. Careful attention to these details helps ensure that the bearing housing integrates seamlessly with the turbocharger system, promoting efficient operation.

Maintenance and Troubleshooting

Routine maintenance practices for the 3525199 Turbocharger Bearing Housing include regular inspections for signs of wear or damage, ensuring that lubrication systems are functioning correctly, and cleaning the housing to remove any debris that could affect performance. Troubleshooting common issues may involve checking for proper alignment, ensuring that lubrication is adequate, and addressing any unusual noises or vibrations that could indicate problems with the bearing housing or associated components.

Performance Enhancements

The 3525199 Turbocharger Bearing Housing contributes to overall engine performance by supporting the efficient operation of the turbocharger. This can lead to improvements in power output, fuel efficiency, and engine reliability. Its role in maintaining the turbocharger’s balance and alignment is key to achieving these performance enhancements.

Cummins: A Brief Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of diesel and natural gas engines. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industries. The company is committed to innovation, quality, and customer satisfaction, making it a preferred choice for engine components, including the 3525199 Turbocharger Bearing Housing.

Compatibility with Cummins Engines

The Turbocharger Bearing Housing (part 3525199) manufactured by Cummins is designed to fit seamlessly with several of their engine models. This part is integral to the turbocharger system, ensuring the smooth operation and longevity of the engine.

6C8.3

The 6C8.3 engine benefits from the Turbocharger Bearing Housing (part 3525199) due to its robust design. This part is engineered to withstand the high-stress environment of the turbocharger, providing a stable platform for the bearings.

L10 MECHANICAL

For the L10 MECHANICAL engine, the Turbocharger Bearing Housing (part 3525199) plays a crucial role in maintaining the integrity of the turbocharger system. The design of this part is tailored to fit the specific requirements of the L10 MECHANICAL engine, ensuring optimal performance and reliability.

QSM11 CM570

The QSM11 CM570 engine also utilizes the Turbocharger Bearing Housing (part 3525199) to support its turbocharger system. This part is crafted to meet the stringent demands of the QSM11 CM570 engine, offering a durable and precise fit.

Understanding the Role of Part 3525199 Turbocharger Bearing Housing in Engine Systems

The part 3525199 Turbocharger Bearing Housing is an essential component in the assembly and functionality of various turbocharger systems. Its role is significant in ensuring the smooth operation of the turbocharger, which is vital for enhancing engine performance.

Integration with Aftermarket Turbochargers

When installing an aftermarket turbocharger, the Turbocharger Bearing Housing (part 3525199) is a key element. It houses the bearings that allow the turbocharger’s shaft to spin at high speeds with minimal friction.

Core and Housing Kit Applications

In core and housing kits, the Turbocharger Bearing Housing plays a pivotal role. These kits often include the core assembly and various housing components. The bearing housing ensures that the turbocharger core is securely mounted and operates within specified tolerances.

Core Assembly Variants

For core assemblies such as H2C, H2D, and H2S, the Turbocharger Bearing Housing (part 3525199) is integral. Each variant may have specific requirements for bearing housing due to differences in design and operational parameters.

Dina Mexico Conv and H2 Turbocharger Systems

In systems like the Dina Mexico Conv and H2 Turbocharger, the bearing housing is a fundamental component. It supports the turbocharger’s rotating assembly, which includes the compressor wheel and turbine wheel.

Performance Parts and Turbocharger Kits

For performance parts and turbocharger kits, the Turbocharger Bearing Housing is a critical component. Whether it’s a pre-set turbine housing kit or a comprehensive turbocharger kit, the bearing housing ensures that the turbocharger can handle increased airflow and pressure without compromising performance.

Turbocharger Repair and Actuator Kits

In turbocharger repair kits and actuator kits, the Turbocharger Bearing Housing (part 3525199) often needs to be inspected or replaced. Wear and tear on the bearing housing can lead to reduced efficiency and potential failure of the turbocharger.

Turbocharger and Connection Systems

Finally, in turbocharger and connection systems, the bearing housing facilitates the secure mounting of the turbocharger to the engine. This connection is vital for the turbocharger to function correctly, transferring exhaust gases efficiently to drive the turbine and compressor.

Conclusion

The Turbocharger Bearing Housing (part 3525199) is a vital component across various turbocharger systems, ensuring efficient and reliable operation. Its proper integration and maintenance are essential for achieving optimal engine performance and durability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.