This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

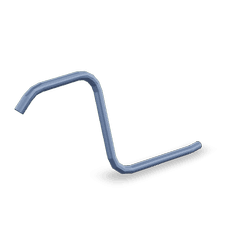

The Turbocharger Oil Drain Connection, identified by Part #3090328, is a component manufactured by Cummins, a leader in diesel engine technology. This part is integral to the maintenance and operation of heavy-duty truck engines, facilitating the efficient drainage of oil from the turbocharger. Understanding its role and functionality is key to maintaining engine performance and reliability.

Basic Concepts of Turbocharger Oil Drain Connection

Turbochargers operate by compressing the air entering the engine, which allows for more fuel to be burned and thus increases power output. A turbocharger is lubricated by engine oil, which is circulated through the turbocharger’s bearings and other moving parts. The Turbocharger Oil Drain Connection plays a role in the system by providing a pathway for the used oil to be drained from the turbocharger. This drainage is necessary to remove contaminants and ensure that fresh, clean oil is circulated, which is vital for the longevity and efficiency of the turbocharger 1.

Role and Function in Truck Operation

In the context of heavy-duty truck engines, the Turbocharger Oil Drain Connection contributes to the turbocharger’s performance by ensuring that oil is efficiently drained. This process helps maintain optimal lubrication, reduces the risk of oil contamination, and supports the turbocharger’s ability to operate under high-stress conditions. By facilitating regular oil changes and drainage, this component plays a part in the overall efficiency and reliability of the engine 2.

Key Features

The Turbocharger Oil Drain Connection is designed with several key features that enhance its functionality. It is constructed from durable materials that can withstand the high temperatures and pressures present in a turbocharger system. The design includes precise fittings and seals to ensure a secure connection and prevent oil leaks. Additionally, the connection is engineered to be compatible with Cummins turbochargers, ensuring a seamless integration into the engine system.

Benefits

The Turbocharger Oil Drain Connection offers several benefits to heavy-duty truck engines. By enabling efficient oil drainage, it helps maintain the turbocharger’s performance and extends its operational life. This can lead to improved engine reliability and potentially lower maintenance costs over time. Furthermore, by ensuring that the turbocharger is properly lubricated, the connection contributes to the overall efficiency of the engine, which can result in better fuel economy and reduced emissions 3.

Troubleshooting and Maintenance

Common issues with the Turbocharger Oil Drain Connection may include leaks or blockages, which can affect the turbocharger’s lubrication. Regular inspection and maintenance are recommended to identify and address these issues promptly. Maintenance practices should include checking for signs of wear or damage, ensuring that connections are secure, and following the manufacturer’s guidelines for oil change intervals. Proper maintenance of this component is vital for the sustained performance and reliability of the turbocharger and the engine as a whole.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong reputation for quality and innovation, Cummins has been at the forefront of diesel engine technology for decades. The company’s commitment to excellence is reflected in its product line, including the Turbocharger Oil Drain Connection, which is designed to meet the demanding requirements of heavy-duty truck engines. Cummins’ expertise in engine technology ensures that their components, like the Turbocharger Oil Drain Connection, are built to deliver reliable performance and durability.

Turbocharger Oil Drain Connection in Cummins Engines

The Turbocharger Oil Drain Connection part 3090328 is a critical component in the maintenance and operation of several Cummins engines. This part is designed to ensure that oil is properly drained from the turbocharger, preventing oil accumulation and ensuring optimal performance.

QSK19 Series

The QSK19 series engines, including the QSK19 CM2350 K114, QSK19 CM500, and QSK19 CM850 MCRS, all utilize the Turbocharger Oil Drain Connection part 3090328. This part is integral to the oil management system of these engines, facilitating the drainage of oil from the turbocharger to the engine’s oil sump. Proper installation and maintenance of this component are essential to prevent oil-related issues that could lead to turbocharger failure or reduced engine efficiency.

Installation and Maintenance

For the QSK19 CM2350 K114, QSK19 CM500, and QSK19 CM850 MCRS engines, the Turbocharger Oil Drain Connection part 3090328 should be installed according to the manufacturer’s specifications. Regular inspection and maintenance of this part are recommended to ensure it remains free from blockages and leaks, which could compromise the turbocharger’s lubrication system.

Importance of the Component

The Turbocharger Oil Drain Connection part 3090328 plays a vital role in the overall health of the engine. By ensuring that oil is effectively drained from the turbocharger, this component helps maintain the integrity of the turbocharger’s bearings and seals, extending the life of the turbocharger and improving engine reliability.

Role of Part 3090328 Turbocharger Oil Drain Connection in Engine Systems

The part 3090328 Turbocharger Oil Drain Connection is an integral component in the maintenance and operation of turbocharger systems within various engine setups. This part facilitates the essential function of draining oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

Integration with Turbocharger Systems

In turbocharger systems, the 3090328 connection is typically situated at the lower section of the turbocharger housing. Its primary role is to allow the used oil, which has lubricated the turbocharger’s moving parts, to be efficiently drained away. This process is vital for preventing oil buildup, which can lead to decreased performance and potential damage to the turbocharger.

Interaction with Plumbing Components

The Turbocharger Oil Drain Connection interfaces directly with the engine’s oil plumbing system. It is connected to oil lines that lead to the oil sump or a dedicated oil collection point. This connection ensures that the drained oil is safely returned to the sump, where it can be re-circulated or properly disposed of. The design of the connection must accommodate the specific flow rates and pressures characteristic of the engine’s oil system to maintain system integrity and performance.

Maintenance and Operational Benefits

By incorporating the 3090328 Turbocharger Oil Drain Connection, engineers and mechanics can more easily perform routine maintenance on the turbocharger. Regular draining of oil helps in identifying contaminants or unusual wear patterns early, allowing for timely interventions that can prevent more severe issues. Additionally, it ensures that the turbocharger remains well-lubricated, enhancing its longevity and efficiency.

Enhanced System Reliability

The presence of an efficient oil drain system, facilitated by the 3090328 connection, contributes to the overall reliability of the engine system. By maintaining clean and adequate lubrication, the turbocharger can operate more smoothly, reducing the risk of overheating and mechanical failures. This, in turn, supports the engine’s performance and durability, making the 3090328 connection a valuable component in the turbocharger’s design.

Conclusion

The Turbocharger Oil Drain Connection, part 3090328, is a critical component in the maintenance and operation of heavy-duty truck engines. By facilitating the efficient drainage of oil from the turbocharger, it ensures optimal lubrication, reduces the risk of oil contamination, and supports the turbocharger’s ability to operate under high-stress conditions. Regular maintenance and proper installation of this component are essential for the sustained performance and reliability of the turbocharger and the engine as a whole.

-

Automotive Emissions Regulations and Exhaust Aftertreatment Systems, John Kasab and Andrea Strzelec, SAE International, 2020.

↩ -

Automotive Technician Training, Second Edition, Tom Denton and Hayley Pells, Routledge, 2022.

↩ -

Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines, Hua Zhao, CRC Press, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.