This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

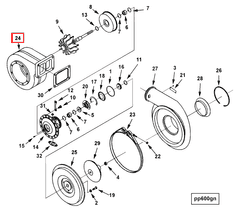

The 4043606 Turbine Housing is a component manufactured by Cummins, a well-established name in the commercial truck industry. This turbine housing is designed for use in turbocharger systems of commercial trucks, playing a significant role in enhancing engine performance and efficiency.

Basic Concepts of Turbine Housing

A turbine housing is a part of the turbocharger system that encases the turbine wheel. Its function is to direct exhaust gases from the engine to spin the turbine wheel, which in turn drives the compressor wheel. This process increases the amount of air entering the engine, thereby boosting power output and efficiency. The design and material of the turbine housing can influence the performance and durability of the turbocharger system 1.

Role of the 4043606 Turbine Housing in Truck Operation

This Cummins part is integral to the operation of a truck’s engine. It works in conjunction with the turbocharger’s compressor housing and the turbine wheel. As exhaust gases exit the engine, they pass through the turbine housing, spinning the turbine wheel. This action drives the compressor wheel, which compresses incoming air before it enters the engine. The efficient design of the 4043606 Turbine Housing ensures optimal airflow and pressure, contributing to the engine’s overall performance 2.

Key Features of the 4043606 Turbine Housing

The 4043606 Turbine Housing boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that can withstand high temperatures and pressures. The design includes precise engineering to ensure efficient airflow and pressure within the turbocharger system. Additionally, the housing may feature unique characteristics such as advanced coatings or specific geometric designs to further improve performance and longevity 3.

Benefits of Using the 4043606 Turbine Housing

Utilizing the 4043606 Turbine Housing in a truck’s engine can lead to several benefits. These include improved engine efficiency due to optimized airflow, increased power output as a result of enhanced turbocharging, and enhanced reliability thanks to the durable construction of the housing. These factors contribute to a more robust and efficient engine operation 4.

Installation Considerations

When installing this part, it is important to ensure compatibility with other turbocharger components. Proper installation involves following manufacturer guidelines to avoid issues such as leaks or inefficient turbocharging. Precautions should be taken to ensure the housing is securely fitted and that all connections are tight and properly sealed.

Troubleshooting Common Issues

Common issues with the 4043606 Turbine Housing may include leaks, inefficient turbocharging, or physical damage to the housing. Troubleshooting steps involve inspecting the housing for signs of wear or damage, checking connections for tightness and proper sealing, and ensuring compatibility with other turbocharger components. Solutions may range from re-sealing connections to replacing damaged parts.

Maintenance Tips

Regular maintenance of the 4043606 Turbine Housing is key to ensuring optimal performance and longevity. This includes routine cleaning to remove any buildup that may obstruct airflow, periodic inspection for signs of wear or damage, and following manufacturer guidelines for replacement intervals. Proper maintenance helps prevent issues and ensures the turbocharger system operates efficiently.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines and components. Their product range includes engines, filtration systems, turbochargers, and related technologies, all designed to meet the demanding requirements of commercial applications.

Cummins Turbine Housing Part 4043606 Compatibility

The Cummins Turbine Housing part number 4043606 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is integral to the engine’s operation, housing the turbine and facilitating the flow of gases through the engine.

K50 Series

The K50 series engines are known for their robust design and efficiency. The Turbine Housing part 4043606 is specifically engineered to fit these engines, providing a secure and efficient housing for the turbine. This ensures that the engine operates smoothly, with minimal wear and tear, and maintains its performance over time.

Grouping of Engines

When considering the compatibility of the Turbine Housing part 4043606, it is essential to understand that it is designed to fit within the K50 series. This grouping ensures that the part is tailored to the specific needs and design of these engines, providing a perfect fit and enhancing the overall performance of the engine.

By ensuring that the Turbine Housing part 4043606 is used with the appropriate engine models, users can expect reliable and efficient operation, contributing to the longevity and effectiveness of their engines.

Role of Part 4043606 Turbine Housing in Engine Systems

The part 4043606 Turbine Housing is an essential component in the efficient operation of various engine systems, particularly when integrated with aftermarket turbochargers. This housing encases the turbine wheel, which is driven by the exhaust gases expelled from the engine.

When paired with a turbocharger, the Turbine Housing plays a significant role in enhancing the performance of the engine. The turbine wheel spins at high speeds due to the force of the exhaust gases, which in turn drives the compressor wheel via a shared shaft. This compressor wheel draws in air, compresses it, and sends it into the engine’s intake system, resulting in increased air density and, consequently, more power.

In engines equipped with a camshaft and gear system, the Turbine Housing works in harmony to optimize the valve timing. As the turbocharger boosts the engine’s air intake, the camshaft ensures that the intake and exhaust valves open and close at the precise moments to maximize efficiency and power output.

The Oil Control Valve (OCV) is another component that benefits from the presence of the Turbine Housing. The OCV regulates the oil flow to the turbocharger’s variable geometry system, if equipped, allowing for adjustments in the turbine’s efficiency based on driving conditions. The Turbine Housing provides the necessary structure and containment for these variable geometry components to function correctly.

In performance-oriented applications, such as those using a turbocharger kit, the Turbine Housing is often upgraded to handle the increased exhaust flow and pressure. This ensures that the turbocharger can operate at peak efficiency, delivering the desired performance gains without compromising reliability.

Overall, the part 4043606 Turbine Housing is a key player in the intricate dance of components that make up modern turbocharged engine systems. Its role in containing and directing exhaust gases to drive the turbine wheel is fundamental to the operation and performance of the turbocharger, camshaft and gear system, Oil Control Valve, and various other parts within the engine.

Conclusion

The 4043606 Turbine Housing is a critical component in the turbocharger system of commercial trucks, designed to enhance engine performance and efficiency. Its precise engineering, durable construction, and compatibility with various engine models make it a valuable asset in the operation of turbocharged engines. Proper installation, maintenance, and troubleshooting are essential to ensure the longevity and optimal performance of this part.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4332824.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.