This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4043603 Turbine Housing is a component manufactured by Cummins, a well-established name in the automotive industry, particularly known for its contributions to heavy-duty truck engines. This turbine housing is integral to the turbocharger system, enhancing the engine’s performance and efficiency.

Basic Concepts of Turbine Housing

A turbine housing is a part of the turbocharger system that directs exhaust gases to spin the turbine wheel. This action compresses the intake air, which is then delivered to the engine’s combustion chambers. The efficiency of this process directly influences the engine’s power output and fuel efficiency 1.

Purpose of the 4043603 Turbine Housing

This part plays a role in the turbocharger system by housing the turbine wheel and directing exhaust gases to spin it. This spinning action compresses the intake air, which is then delivered to the engine, enhancing its performance. It interacts with other turbocharger components, such as the compressor housing and the center housing, to ensure optimal turbocharger operation.

Key Features

The 4043603 is designed with specific features that enhance its performance and durability. It is constructed from high-quality materials that provide structural integrity and resistance to high temperatures and pressures. Its design includes precise engineering to ensure efficient exhaust gas flow and optimal turbocharger performance.

Benefits

This Cummins part offers several advantages. It contributes to improved engine efficiency by ensuring efficient turbocharger operation. Its durable construction enhances the longevity of the turbocharger system. Additionally, it can provide performance gains by optimizing the turbocharger’s ability to compress intake air, leading to increased power output and better fuel efficiency.

Installation Considerations

Proper installation of this part is crucial for ensuring optimal turbocharger performance. It is compatible with various engine models and turbocharger systems, but it is important to follow manufacturer guidelines to ensure correct fitment and operation. This includes checking for proper alignment, secure fastening, and correct gasket installation.

Troubleshooting and Maintenance

Common issues with turbine housings can include leaks, cracks, or inefficient exhaust gas flow. Regular inspection and maintenance can help identify these issues early. Diagnostic procedures may involve visual inspection, pressure testing, and performance monitoring. Maintenance tips include keeping the housing clean, inspecting for damage regularly, and replacing gaskets as needed to ensure a secure seal.

Performance Impact

The 4043603 influences engine performance by optimizing the turbocharger’s ability to compress intake air. This can lead to increased power output, improved fuel efficiency, and enhanced overall drivability. Its efficient design and durable construction contribute to these performance benefits.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, particularly in the heavy-duty truck sector, Cummins is known for its innovative solutions and commitment to quality. The company’s extensive product range and history of excellence make it a trusted name in the industry.

Application in Cummins Engines

The Turbine Housing part 4043603 is compatible with several Cummins engine models. Here are some of the engines where this part is utilized:

- K50 Series: The K50 series engines, known for their robust design and high performance, incorporate the Turbine Housing part 4043603. This part ensures that the turbocharger operates smoothly, contributing to the engine’s overall efficiency and power output.

The Turbine Housing part 4043603 is engineered to withstand the high temperatures and pressures within the engine’s exhaust system. Its design facilitates the effective transfer of energy from the exhaust gases to the turbine wheel, enhancing the engine’s responsiveness and performance. This component is essential for maintaining the integrity of the turbocharger system and ensuring that the engine operates at peak efficiency.

Role of Part 4043603 Turbine Housing in Engine Systems

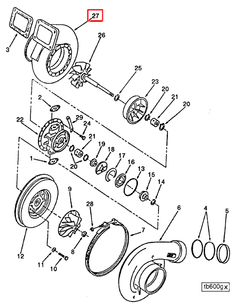

Part 4043603, the Turbine Housing, is an integral component in the operation of aftermarket turbochargers and turbocharger kits. Its primary function is to house the turbine wheel, which is driven by the exhaust gases expelled from the engine. This housing is designed to optimize the flow of these gases, enhancing the efficiency of the turbocharger.

When integrated into a turbocharger kit, the Turbine Housing works in conjunction with the compressor housing to balance the airflow through the system. The turbine wheel, spinning at high speeds due to the exhaust flow, drives the compressor wheel via a shared shaft. This setup increases the volume of air entering the engine, thereby boosting power output.

In performance applications, the Turbine Housing is often modified or upgraded to handle increased airflow demands. This can involve changes to the housing’s design to improve exhaust gas velocity and reduce backpressure. Such modifications are essential for maximizing the potential of high-performance turbochargers.

The Turbine Housing also plays a role in thermal management within the turbocharger system. By efficiently directing exhaust gases, it helps in maintaining optimal temperatures for both the turbine and compressor components, contributing to the overall reliability and performance of the turbocharger 2.

Conclusion

The 4043603 Turbine Housing is a critical component in the turbocharger system, designed to enhance engine performance and efficiency. Its durable construction, precise engineering, and compatibility with various engine models make it a valuable part for both standard and performance applications. Proper installation, regular maintenance, and understanding its role in the turbocharger system are essential for maximizing its benefits and ensuring optimal engine operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.