This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

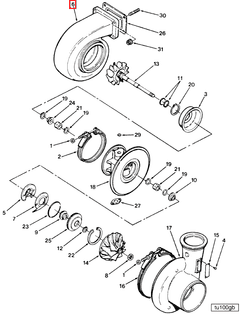

The Cummins 3536998 Turbine Housing is a component designed for use in heavy-duty truck engines. It plays a role in the turbocharger system, which is integral to the operation of these engines. Understanding the function and importance of turbine housings can provide insight into how they contribute to engine performance and efficiency.

Basic Concepts of Turbine Housings

A turbine housing is a part of the turbocharger system that encases the turbine wheel. Its function is to direct exhaust gases onto the turbine wheel, which spins and drives the compressor wheel on the other side of the turbocharger. This process increases the amount of air entering the engine, thereby enhancing combustion efficiency and power output. The turbine housing works in conjunction with other turbocharger components, such as the compressor housing and the center housing, to optimize engine performance 1.

Purpose of the 3536998 Turbine Housing

This Cummins part is specifically engineered to improve the efficiency and power output of a truck’s engine. By effectively channeling exhaust gases, it ensures that the turbine wheel operates at optimal speeds. This, in turn, allows the compressor to deliver a greater volume of air into the engine, resulting in more efficient combustion and increased power.

Key Features

The 3536998 is characterized by several key features. It is constructed from durable materials that can withstand high temperatures and pressures. The design includes precise engineering to ensure efficient gas flow and minimal turbulence. Additionally, it may feature unique characteristics such as advanced coatings or specific geometric shapes that enhance performance and durability.

Benefits

Using this part offers several benefits. It contributes to enhanced engine performance by improving the efficiency of the turbocharger system. This can lead to better fuel efficiency, as the engine requires less fuel to produce the same amount of power. Furthermore, the durable construction of the housing ensures longevity, reducing the need for frequent replacements 2.

Installation Considerations

Proper installation of the Turbine Housing is vital for ensuring optimal performance and longevity. It is important to follow manufacturer guidelines to ensure compatibility with the specific engine model. Correct installation procedures help prevent issues such as leaks or inefficient gas flow, which can adversely affect engine performance.

Troubleshooting and Maintenance

Common issues with turbine housings may include cracks, leaks, or inefficient gas flow. Regular inspection and maintenance can help identify these issues early. Maintenance tips include checking for signs of wear or damage, ensuring proper gasket installation, and following recommended service intervals. Addressing issues promptly can help maintain the housing’s performance and extend its lifespan.

Performance Impact

The 3536998 plays a role in the overall performance of the truck’s engine by enhancing the efficiency of the turbocharger system. Real-world applications and user experiences often highlight improvements in engine responsiveness, power output, and fuel efficiency when this housing is properly installed and maintained.

Cummins Overview

Cummins Inc. is a well-established company with a strong reputation in the automotive and heavy-duty truck industry. Founded in 1919, Cummins has a history of innovation and quality in manufacturing engine components, including turbine housings. The company’s commitment to quality and continuous improvement ensures that its products, like the 3536998 Turbine Housing, meet high standards of performance and reliability.

Role of 3536998 Turbine Housing in Engine Systems

This part is an essential component in the operation of aftermarket turbochargers and turbocharger kits. This housing encases the turbine wheel, which is driven by the exhaust gases expelled from the engine. As the exhaust gases flow through the turbine housing, they spin the turbine wheel at high speeds. This rotational energy is then transferred via the turbocharger’s shaft to the compressor wheel.

In a performance-oriented setup, the turbine housing plays a significant role in determining the turbocharger’s efficiency and response. The design and size of the turbine housing affect the flow characteristics of the exhaust gases. A smaller turbine housing, often referred to as a “hot side” or “exhaust side” housing, can provide quicker spool-up, meaning the turbocharger reaches operating speed more rapidly. This is particularly beneficial in applications where low-end torque and responsiveness are prioritized.

Conversely, a larger turbine housing allows for greater exhaust flow, which can support higher boost levels and power output. This is advantageous in applications where top-end power is more critical. The choice between smaller and larger turbine housings often depends on the specific performance goals of the engine build.

When integrating the 3536998 Turbine Housing into a turbocharger kit, it is important to consider the overall system design. The housing must be compatible with the turbocharger’s compressor side, ensuring a balanced system that optimizes both air intake and exhaust efficiency. Additionally, the housing should be designed to withstand the high temperatures and pressures generated by the exhaust gases, ensuring durability and reliability in high-performance applications.

Conclusion

In summary, the 3536998 Turbine Housing is a key component in the efficient operation of aftermarket turbochargers. Its design and size significantly influence the turbocharger’s performance characteristics, making it a vital consideration in any engine system upgrade.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.