This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

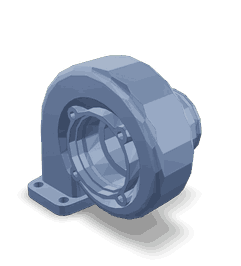

The Turbine Housing 3536617, a component manufactured by Cummins, is specifically designed for use in turbocharger systems of heavy-duty truck engines. This part plays a significant role in the turbocharger system by directing exhaust gases to spin the turbine wheel, which in turn drives the compressor wheel to increase air intake into the engine. Its design and functionality are integral to enhancing engine performance and efficiency in demanding applications 1.

Basic Concepts of Turbine Housing

Turbine housings are fundamental components within turbocharger systems. They serve to channel exhaust gases from the engine to the turbine wheel. The efficiency of this process directly influences the turbocharger’s ability to compress intake air, thereby affecting engine power output and fuel efficiency. The design of the turbine housing, including its shape and the smoothness of the internal passages, plays a role in minimizing turbulence and maximizing the velocity of exhaust gases, which contributes to the overall performance of the turbocharger 2.

Purpose of Turbine Housing 3536617

The Turbine Housing 3536617 is engineered to optimize the flow of exhaust gases in the turbocharger system of heavy-duty trucks. By efficiently directing these gases, it enhances the spin of the turbine wheel, which drives the compressor wheel to increase the volume of air entering the engine. This process is vital for improving engine efficiency and power output, allowing the engine to perform more effectively under various load conditions 3.

Key Features

The Turbine Housing 3536617 is characterized by its robust design and high-quality material composition, which contribute to its performance and durability. Its engineering specifications are tailored to meet the demanding requirements of heavy-duty truck engines, ensuring reliable operation and longevity. The housing’s design facilitates efficient exhaust gas flow, which is crucial for the turbocharger’s performance 4.

Benefits

The advantages of the Turbine Housing 3536617 include improved engine performance, increased fuel efficiency, and enhanced durability under demanding conditions. By optimizing the turbocharger’s operation, this housing contributes to higher power output and better engine responsiveness. Its durable construction ensures long-term reliability, even in the harsh environments typical of heavy-duty truck applications.

Installation and Compatibility

Proper installation of the Turbine Housing 3536617 is vital for ensuring its optimal performance and compatibility with various Cummins engine models and turbocharger systems. Following manufacturer guidelines during installation helps maintain the integrity of the turbocharger system and ensures that the housing functions as intended within the engine’s operating parameters.

Maintenance and Troubleshooting

Routine maintenance practices are recommended to ensure the longevity and optimal performance of the Turbine Housing 3536617. Regular inspections for signs of wear or damage, cleaning to remove any buildup that could impede airflow, and ensuring all connections are secure are important maintenance steps. Troubleshooting common issues, such as leaks or reduced efficiency, often involves checking for proper installation and condition of the housing and related components.

Performance Enhancements

The Turbine Housing 3536617 contributes to overall engine performance by enhancing power output, torque, and efficiency. Its design and functionality within the turbocharger system allow for more effective utilization of exhaust gases, leading to improved engine responsiveness and efficiency. These enhancements are particularly beneficial in heavy-duty truck applications, where engine performance and fuel efficiency are critical.

Thermal Management

The Turbine Housing 3536617 plays a role in managing exhaust gas temperatures, which impacts turbocharger efficiency and engine reliability. By efficiently directing exhaust gases and optimizing their flow, the housing helps maintain optimal turbocharger operation under varying engine loads and temperatures. This thermal management is crucial for preserving the integrity of the turbocharger and ensuring consistent engine performance.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for its commitment to innovation and quality in manufacturing turbocharger components. With a rich history of providing reliable and high-performance engine solutions, Cummins has established a reputation for excellence in the design and production of turbocharger housings and other critical engine components. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a trusted provider in the industry.

Role of Part 3536617 Turbine Housing in Engine Systems

The Turbine Housing, identified by part number 3536617, is an essential component in the operation of aftermarket turbochargers, standard turbochargers, and turbocharger kits. This housing encases the turbine wheel, which is driven by the exhaust gases exiting the engine. As the exhaust gases flow through the housing, they spin the turbine wheel at high speeds. This rotational energy is then transferred via the shaft to the compressor wheel, which compresses the intake air before it enters the engine’s combustion chambers.

In an aftermarket turbocharger setup, the 3536617 Turbine Housing is often utilized to enhance the performance capabilities beyond the stock specifications. It is engineered to handle increased exhaust flow and higher temperatures, which are typical in modified engine systems where greater power output is desired. The housing’s design can significantly affect the turbocharger’s efficiency and response, influencing the overall performance of the engine.

When integrated into a turbocharger kit, the Turbine Housing works in concert with other components such as the compressor housing, center housing, and the turbocharger’s internals. The kit is designed to provide a balanced system that optimizes the flow of exhaust gases and intake air, ensuring that the engine operates at peak efficiency.

The Turbine Housing also plays a part in the thermal management of the turbocharger system. Its material and design contribute to dissipating heat away from the turbine wheel and the shaft, which is vital for maintaining the integrity and longevity of the turbocharger’s components.

Conclusion

In summary, the 3536617 Turbine Housing is a pivotal element in the turbocharger’s ability to increase an engine’s power and efficiency. Its interaction with exhaust gases, and subsequent energy transfer to the compressor side, is fundamental to the forced induction process that defines turbocharged engine performance.

-

Automotive Braking Systems, Nicholas Goodnight and Kirk Van Gelder, Jones & Bartlett Learning, 2018.

↩ -

Simulation and Optimization of Internal Combustion Engines, Zhiyu Han, SAE International, 2022.

↩ -

Diesel and Gasoline Engines, Richard Viskup, IntechOpen, 2020.

↩ -

Modeling Engine Spray and Combustion Processes, Gunnar Stiesch, Springer Verlag, 2003.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.