Introduction

The Turbine Housing 3536014 by Cummins is a vital component in the turbocharger system of heavy-duty trucks. It enhances engine performance by facilitating efficient airflow and pressure management within the turbocharger. This housing is designed to meet the demanding requirements of heavy-duty applications, ensuring reliable and robust operation under various conditions.

Basic Concepts of Turbine Housing

Turbine housings are integral to the functionality of turbochargers. They encase the turbine wheel, which is driven by the engine’s exhaust gases. As the exhaust gases pass through the housing, they spin the turbine wheel, which in turn drives the compressor wheel. This process increases the volume and pressure of the air entering the engine, thereby enhancing combustion efficiency and power output. The design and material of the turbine housing directly influence the turbocharger’s performance and durability 1.

Purpose of the 3536014 Turbine Housing

The 3536014 Turbine Housing is engineered to optimize the operation of a truck’s engine by efficiently managing the flow of exhaust gases. It houses the turbine wheel, which is spun by these gases, driving the compressor wheel to increase the air supply to the engine. This component ensures that the turbocharger operates within its designed parameters, contributing to improved engine efficiency, increased power output, and enhanced overall performance.

Key Features

The 3536014 Turbine Housing boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to heat and corrosion. The design includes precise engineering to maintain optimal airflow and pressure within the turbocharger system. Additionally, it features robust mounting points and seals to prevent leaks and ensure a secure fit within the engine system.

Benefits

The 3536014 Turbine Housing offers numerous benefits for heavy-duty truck applications. It contributes to improved engine efficiency by ensuring that the turbocharger operates effectively. This results in increased power output, allowing the engine to perform better under demanding conditions. Furthermore, the durable construction and precise engineering of the housing enhance its reliability, reducing the likelihood of failures and extending the service life of the turbocharger system.

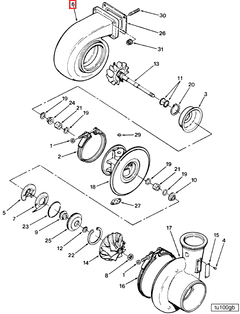

Installation Process

Proper installation of the 3536014 Turbine Housing is crucial for ensuring optimal performance. The process involves several steps:

- Ensure the engine bay is clean and free of debris.

- Align the housing with the turbocharger and engine mounting points.

- Secure the housing using the appropriate bolts and torque specifications.

- Check all connections and seals to prevent leaks.

- Perform a system check to ensure the turbocharger operates within its designed parameters.

Common Issues and Troubleshooting

Common issues with the 3536014 Turbine Housing may include leaks, cracks, or a decline in performance. These issues can often be traced to improper installation, wear and tear, or exposure to extreme conditions. Troubleshooting tips include:

- Inspecting all seals and connections for signs of wear or damage.

- Checking for cracks or deformities in the housing.

- Ensuring proper alignment and secure mounting.

- Addressing any leaks promptly to prevent further damage.

Maintenance Tips

Regular maintenance of the 3536014 Turbine Housing is essential for prolonging its service life and ensuring optimal performance. Maintenance tips include:

- Conducting regular inspections for signs of wear, cracks, or leaks.

- Cleaning the housing to remove any buildup of soot or debris.

- Ensuring all seals and connections are intact and secure.

- Following the manufacturer’s recommended maintenance schedule for the turbocharger system.

Compatibility and Application

The 3536014 Turbine Housing is designed for specific models and makes of heavy-duty trucks. It is compatible with a range of Cummins engines, ensuring seamless integration and optimal performance. Notable applications include use in long-haul trucking, construction equipment, and other heavy-duty industries where reliable and efficient engine performance is paramount.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s expertise in diesel engine manufacturing is evident in its comprehensive range of products, which are designed to meet the rigorous demands of heavy-duty applications 2.

Turbine Housing (Part 3536014) in Cummins Engines

The Turbine Housing (part 3536014) is a critical component in several Cummins engine models, including the N14 CELECT PLUS. This part is integral to the engine’s turbocharger system, facilitating the efficient transfer of exhaust gases to the turbine wheel.

In the N14 CELECT PLUS engine, the turbine housing is designed to withstand high temperatures and pressures, ensuring optimal performance and longevity. It is engineered to provide a smooth flow path for exhaust gases, which drives the turbine wheel and subsequently the compressor, enhancing the engine’s overall efficiency.

The turbine housing’s design is crucial for maintaining the structural integrity of the turbocharger system. It is typically made from high-strength materials that can endure the harsh operating conditions within the engine. The precise fit and alignment of this part are essential for the turbocharger to function correctly, ensuring that the engine operates at peak performance levels.

In the broader context of Cummins engines, the turbine housing is a standardized component across various models, including but not limited to the N14 CELECT PLUS. This standardization allows for easier maintenance and repair, as technicians can use familiar procedures and parts across different engine types. The turbine housing’s role in the engine’s turbocharger system is consistent, making it a vital part in the performance and reliability of Cummins engines.

Role of Part 3536014 Turbine Housing in Engine Systems

The Turbine Housing (Part 3536014) is an integral component in the operation of a turbocharger system. It is responsible for directing the exhaust gases from the engine to spin the turbine wheel, which in turn drives the compressor wheel. This process is fundamental to the function of the turbocharger, as it compresses the intake air, allowing more air to enter the engine’s combustion chambers. Consequently, this leads to enhanced engine performance and efficiency 3.

When integrated into a Turbocharger Kit, the Turbine Housing works in concert with other components such as the compressor housing, center housing, and the turbocharger itself. The efficiency of the Turbine Housing directly influences the overall performance of the turbocharger. A well-designed Turbine Housing ensures that exhaust gases are efficiently channeled, minimizing energy loss and maximizing the spin of the turbine wheel.

In terms of Parts interaction, the Turbine Housing connects to the engine’s exhaust system via an exhaust manifold or downpipe. This connection must be secure to prevent exhaust leaks, which can reduce turbocharger efficiency and potentially cause damage to other engine components.

The performance of the engine is significantly impacted by the Turbine Housing. A housing that is too small can restrict exhaust flow, leading to reduced turbocharger efficiency. Conversely, a housing that is too large may result in slower spool-up times, affecting the responsiveness of the turbocharger. Therefore, the Turbine Housing must be carefully matched to the specific engine and driving conditions to optimize performance.

Conclusion

The Turbine Housing 3536014 by Cummins is a critical component in the turbocharger system of heavy-duty trucks. Its role in managing exhaust gases and driving the turbine wheel is essential for enhancing engine performance and efficiency. Proper installation, regular maintenance, and understanding its compatibility and application are key to ensuring optimal performance and longevity of the turbocharger system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.