This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

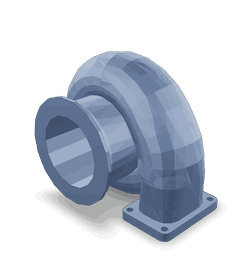

The Cummins 3524065 Turbine Housing is a critical component in turbocharger systems, specifically designed for heavy-duty trucks. It enhances the efficiency and performance of the engine by optimizing the flow of exhaust gases over the turbine wheel. This part is integral to the turbocharger system, contributing to increased engine power output and improved fuel economy.

Basic Concepts of Turbine Housing

Turbine housings are essential for the functionality of turbocharger systems. They encase the turbine wheel, which is driven by exhaust gases exiting the engine. This action spins the compressor wheel, compressing incoming air before it enters the engine’s combustion chambers. The design and efficiency of the turbine housing directly impact the turbocharger’s performance, affecting engine power and efficiency 1.

Purpose of the 3524065 Turbine Housing

This Cummins part optimizes the flow of exhaust gases over the turbine wheel, enhancing turbocharger efficiency and engine performance. By effectively managing exhaust gas flow, it contributes to increased engine power output and improved fuel economy, making it a vital component in heavy-duty truck engines 2.

Key Features

The 3524065 Turbine Housing is characterized by its robust design and high-quality material composition, including durable alloys resistant to high temperatures and pressures. Its design maximizes turbine efficiency while minimizing the risk of leaks or efficiency losses. Precision machining and heat treatment processes enhance its performance and durability, ensuring long-term reliability in demanding applications.

Benefits

The advantages of this part include improved turbocharger efficiency, leading to enhanced engine performance. Its design contributes to potential increases in fuel economy by ensuring the turbocharger operates at peak efficiency. Additionally, the housing’s durability and resistance to wear and tear support long-term engine reliability and performance.

Installation Process

Proper installation of the 3524065 Turbine Housing involves preparing the turbocharger and engine components for the housing’s attachment. Careful alignment and secure fastening are important to prevent leaks and ensure efficient operation. Following manufacturer guidelines for torque specifications and gasket replacement is crucial for maintaining the integrity of the turbocharger system.

Common Issues and Troubleshooting

Typical problems associated with turbine housings include leaks and efficiency losses, often due to wear, improper installation, or damage. Troubleshooting these issues involves inspecting the housing for signs of wear or damage, checking for proper alignment and secure fastening, and ensuring that all gaskets and seals are in good condition. Addressing these issues promptly can help maintain the efficiency and performance of the turbocharger system.

Maintenance Tips

Regular maintenance practices are important for prolonging the lifespan of the 3524065 Turbine Housing. This includes routine inspections for signs of wear or damage, cleaning the housing to remove any buildup that could affect performance, and replacing gaskets and seals as needed. Adhering to these maintenance routines can help ensure the housing continues to operate efficiently and contribute to the overall performance of the engine.

Performance Enhancements

Potential upgrades or modifications to the 3524065 Turbine Housing can further enhance turbocharger performance and engine output. These may include installing a housing with a different design for specific performance characteristics or upgrading materials for increased durability. Careful consideration of the engine’s requirements and the desired performance outcomes is important when exploring these enhancements.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and related components, with a reputation for quality and reliability. Founded in 1919, Cummins has a long history of innovation and excellence in the diesel engine industry. The company’s commitment to quality is evident in its products, including the 3524065 Turbine Housing, which is designed to meet the demanding requirements of heavy-duty truck applications.

Compatibility

The 3524065 Turbine Housing is compatible with several engine models, ensuring efficient operation and performance. This part is integral to the engine’s turbocharger system, facilitating the flow of exhaust gases and contributing to the overall power output.

K50 Series

In the K50 series engines, the Turbine Housing part 3524065 is designed to fit seamlessly into the turbocharger assembly. This housing directs the high-speed exhaust gases from the engine’s combustion chamber to the turbine wheel, which in turn drives the compressor. The precision engineering of this part ensures minimal resistance and maximum efficiency, enhancing the engine’s performance and reliability.

Grouping by Application

For applications requiring robust and high-performance engines, the K50 series with the Turbine Housing 3524065 is a preferred choice. This part is engineered to withstand the demanding conditions of heavy-duty operations, providing durability and consistent performance over extended periods.

The compatibility of the Turbine Housing part 3524065 across various K50 engines underscores its versatility and importance in maintaining the engine’s efficiency and longevity.

Role of Part 3524065 Turbine Housing in Engine Systems

The Turbine Housing, identified by part number 3524065, is an integral component in the functionality of various engine systems, particularly when integrated with aftermarket turbochargers and turbocharger kits.

When paired with an aftermarket turbocharger, the Turbine Housing plays a significant role in optimizing the turbocharger’s performance. It houses the turbine wheel, which is spun by the exhaust gases exiting the engine. The design and material of the Turbine Housing affect the efficiency of this process, influencing the overall performance of the turbocharger.

In the context of a Turbo T18A KV16 setup, the Turbine Housing is essential for maintaining the correct flow of exhaust gases. Its design helps in managing the pressure and temperature of these gases, which are vital for the efficient operation of the turbocharger.

For performance parts and performance-oriented turbocharger kits, the Turbine Housing is often a point of modification. Engineers and mechanics may select specific Turbine Housings to fine-tune the turbocharger’s response, power output, and efficiency. This customization is key in achieving the desired performance characteristics in high-performance engine systems.

Conclusion

The Turbine Housing (part 3524065) is a fundamental component in the effective operation of turbochargers and turbocharger kits. Its role in managing exhaust gas flow, pressure, and temperature is vital for the performance and efficiency of these systems. Regular maintenance, proper installation, and consideration of performance enhancements can further optimize its functionality and contribute to the overall performance of heavy-duty truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.