This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

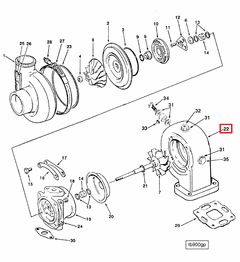

The Cummins 3523243 Turbine Housing is a component designed for use in turbocharger systems of heavy-duty trucks. Its purpose is to enhance the efficiency and power output of the engine by optimizing the flow of exhaust gases. Turbine housings play a significant role in the operation of turbochargers, which are vital for improving engine performance in heavy-duty applications 1.

Basic Concepts of Turbine Housings

A turbine housing is a part of the turbocharger system that encloses the turbine wheel. Its function is to direct exhaust gases from the engine to spin the turbine wheel, which in turn drives the compressor wheel to increase the air intake. This process, known as turbocharging, enhances engine performance by allowing more air into the combustion chamber, thereby enabling more fuel to be burned and producing more power. The design and efficiency of the turbine housing are crucial for the overall performance of the turbocharger 2.

Purpose of the 3523243 Turbine Housing

The Cummins 3523243 Turbine Housing is specifically engineered to improve the operation of a truck’s engine. By optimizing the flow of exhaust gases, it aids in spinning the turbine wheel more efficiently, which leads to better compressor performance. This results in improved engine efficiency and increased power output, making it a valuable component for heavy-duty truck engines 3.

Key Features

The Cummins 3523243 Turbine Housing features a design that maximizes the efficiency of exhaust gas flow. It is constructed from high-quality materials that ensure durability and resistance to the high temperatures and pressures of the exhaust system. Unique characteristics such as precise engineering and robust construction enhance its performance and longevity.

Benefits

Using the Cummins 3523243 Turbine Housing offers several benefits, including improved engine performance, increased fuel efficiency, and enhanced durability. These advantages contribute to better overall truck performance, making it a reliable choice for heavy-duty applications.

Installation Considerations

Proper installation of the 3523243 Turbine Housing is important for optimal performance and longevity. Guidelines for installation include ensuring a proper seal to prevent exhaust leaks, correct alignment with the turbocharger, and secure fastening to withstand the rigors of heavy-duty use.

Troubleshooting and Maintenance

Common issues with turbine housings may include leaks, cracks, or reduced efficiency due to buildup. Troubleshooting steps involve inspecting for physical damage, checking for proper seals, and cleaning or replacing the housing if necessary. Regular maintenance, such as inspecting for wear and ensuring proper operation, can help ensure the longevity and efficient operation of the turbine housing.

Performance Enhancements

The 3523243 Turbine Housing contributes to performance enhancements in heavy-duty trucks by improving the efficiency of the turbocharger system. Real-world applications have shown improvements in engine power and fuel efficiency, demonstrating the value of this component in enhancing truck performance.

Compatibility and Applications

The Cummins 3523243 Turbine Housing is designed for use with specific Cummins engine models and is applicable in various types of heavy-duty trucks. Its compatibility ensures that it can be integrated into existing systems with minimal modifications, providing a reliable upgrade for improved performance.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer of diesel engines and related technologies. With a history of innovation and quality, Cummins plays a significant role in the automotive industry, particularly in the production of diesel engines and components like the 3523243 Turbine Housing. The company’s commitment to excellence ensures that its products meet the demanding requirements of heavy-duty applications.

Cummins Turbine Housing Part 3523243 Compatibility

The Cummins Turbine Housing part 3523243 is a critical component designed to fit seamlessly within specific engine models. This part is engineered to ensure optimal performance and durability, making it a vital element in the engine’s operation.

Engine Compatibility

- 4B3.9 and 6B5.9 Engines

The Turbine Housing part 3523243 is specifically designed to integrate with the Cummins 4B3.9 and 6B5.9 engines. These engines are known for their robust construction and reliability, often used in heavy-duty applications where performance and longevity are paramount.

- Grouping of Engines

Both the 4B3.9 and 6B5.9 engines share common design principles and specifications, making the Turbine Housing part 3523243 a suitable fit for either model. This compatibility ensures that users can maintain and repair their engines with confidence, knowing that the part is designed to meet the specific requirements of these engines.

- Installation and Performance

When installed correctly, the Turbine Housing part 3523243 ensures that the engine operates efficiently. It plays a crucial role in managing the airflow and pressure within the engine, contributing to overall performance and reliability. Proper installation is essential to maintain the integrity of the engine and prevent potential issues that could arise from a poorly fitted component.

Role of Part 3523243 Turbine Housing in Engine Systems

The part 3523243 Turbine Housing is an essential component in the operation of various engine systems, particularly when integrated with aftermarket turbochargers, standard turbochargers, and turbocharger kits.

Integration with Aftermarket Turbochargers

When utilized with an aftermarket turbocharger, the 3523243 Turbine Housing plays a significant role in enhancing the turbocharger’s efficiency. It is responsible for directing the flow of exhaust gases, which spin the turbine wheel. This, in turn, drives the compressor wheel, increasing the air supply to the engine. The housing’s design affects the pressure ratio and the overall performance of the turbocharger. A well-designed turbine housing can lead to improved throttle response and power output.

Function in Standard Turbochargers

In standard turbocharger setups, the 3523243 Turbine Housing ensures that the exhaust gases are efficiently channeled to the turbine. This efficient channeling is vital for maintaining the balance between the turbine and compressor sides of the turbocharger. The housing’s design impacts the turbocharger’s ability to spool up quickly, which is essential for responsive acceleration and overall engine performance.

Importance in Turbocharger Kits

When part of a turbocharger kit, the 3523243 Turbine Housing works in conjunction with other components such as the compressor housing, center housing, and wastegate. The housing’s role is to optimize the flow of exhaust gases, which is critical for the kit’s intended performance gains. Whether the kit is designed for increased power, improved fuel efficiency, or better drivability, the turbine housing is a key element that contributes to achieving these goals.

In all these applications, the 3523243 Turbine Housing is integral to the turbocharger’s function, influencing both the efficiency and performance of the engine system.

Conclusion

The Cummins 3523243 Turbine Housing is a critical component in the turbocharger systems of heavy-duty trucks. Its design and functionality are essential for optimizing engine performance, enhancing power output, and improving fuel efficiency. Proper installation, regular maintenance, and understanding its role within various engine systems are key to maximizing the benefits of this part. Cummins’ commitment to quality and innovation ensures that the 3523243 Turbine Housing meets the demanding requirements of heavy-duty applications, providing reliable and efficient performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.