This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

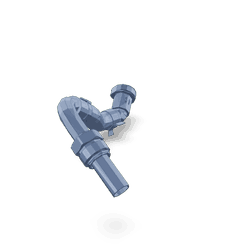

Introduction to Pressure Sensing Tubes

Pressure sensing tubes are vital components in modern engines, especially in commercial trucks. These tubes are designed to monitor and transmit pressure data from various engine parts to the vehicle’s electronic control unit (ECU) 1. Accurate pressure readings are essential for optimizing engine performance, ensuring safety, and maintaining efficiency.

How a Pressure Sensing Tube Works

A pressure sensing tube, such as the Cummins part #5418429, is typically made from a flexible, pressure-resistant material capable of withstanding high temperatures and pressures. The tube is connected to a pressure sensor, which converts pressure variations into electrical signals. These signals are then relayed to the ECU, which uses the data to adjust engine parameters in real-time 2.

The pressure sensing tube must be meticulously calibrated to ensure precise readings. Any inaccuracies can result in suboptimal engine performance, increased fuel consumption, and potential engine damage.

Purpose of the Cummins Pressure Sensing Tube (Part #5418429)

The Cummins pressure sensing tube (part #5418429) is vital for the operation of commercial trucks, providing real-time data on engine pressure. This information is essential for several key functions:

- Turbocharger Boost Control: The tube monitors boost pressure in turbocharged engines, ensuring the turbocharger operates within safe limits.

- Fuel Injection Timing: Accurate pressure readings help optimize fuel injection timing, which is critical for performance and fuel efficiency.

- Engine Protection: By monitoring pressure levels, the tube helps prevent over-pressurization, which can lead to engine damage.

- Emissions Control: The data from the pressure sensing tube aids in maintaining optimal combustion conditions, which helps reduce harmful emissions.

Troubleshooting the Cummins Pressure Sensing Tube (Part #5418429)

Regular maintenance and timely troubleshooting are crucial to ensure the longevity and performance of the pressure sensing tube. Here are some common issues and their solutions:

- Leaks: If the tube is leaking, it can cause inaccurate pressure readings. Inspect the tube for any visible damage or wear and replace it if necessary.

- Blockages: Debris or contaminants can block the tube, leading to incorrect pressure readings. Clean the tube thoroughly and ensure it is free from obstructions.

- Connection Issues: Ensure that the tube is securely connected to the pressure sensor and the ECU. Loose connections can lead to intermittent or inaccurate readings.

- Sensor Malfunction: If the pressure sensor is malfunctioning, it can affect the accuracy of the readings. Test the sensor and replace it if it is faulty.

Maintenance Tips for the Cummins Pressure Sensing Tube (Part #5418429)

To maintain the performance of the pressure sensing tube, follow these best practices:

- Regular Inspections: Conduct regular visual inspections of the tube for any signs of wear, cracks, or leaks.

- Cleaning: Keep the tube and its connections clean to prevent blockages and ensure accurate readings.

- Secure Connections: Regularly check that all connections are secure and free from corrosion.

- Professional Servicing: Have the tube and sensor checked by a professional technician during routine maintenance intervals.

About Cummins

Cummins is a global power leader and a pioneer in the design and manufacture of engines, engine-related technology, and related parts and services. With a reputation for quality and reliability, Cummins products are trusted by fleet operators and mechanics worldwide. The company’s commitment to innovation and excellence ensures that its parts, such as the pressure sensing tube (part #5418429), meet the highest standards of performance and durability.

Conclusion

By understanding the critical role of the Cummins pressure sensing tube (part #5418429) and implementing proper maintenance and troubleshooting practices, engineers, mechanics, and fleet operators can ensure the optimal performance and longevity of their commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.