This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

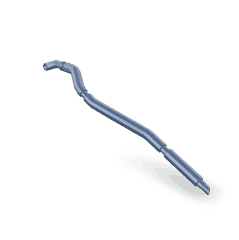

The Cummins 5335924 Breather Tube is a vital component for commercial trucks, designed to enhance engine efficiency and reliability. Understanding its function and operation is essential for maintaining the engine’s health and performance.

Basic Concepts of Breather Tubes

Breather tubes are integral to engine systems, allowing for pressure release and air exchange within the engine compartment. They maintain a balanced pressure environment, crucial for engine function. By facilitating air circulation and escape, breather tubes prevent the accumulation of harmful gases and moisture, which can cause engine damage over time 1.

Purpose of the Cummins 5335924 Breather Tube

The Cummins 5335924 Breather Tube is engineered to regulate pressure and enable ventilation within the truck’s engine system. It releases excess pressure and circulates air, maintaining optimal engine conditions. This ensures the engine operates within safe pressure limits and effectively vents contaminants or moisture, contributing to engine longevity and performance 2.

Key Features

Constructed from durable materials, the Cummins 5335924 Breather Tube is designed to withstand harsh engine conditions. Its design ensures efficient airflow and pressure regulation. It may also include unique features that enhance its performance and integration within the engine system 3.

Benefits

Utilizing the Cummins 5335924 Breather Tube offers several advantages. It improves engine performance by ensuring optimal operating conditions. The breather tube enhances engine longevity by preventing damage from pressure buildup and moisture. It also increases the reliability of the truck’s engine system by maintaining consistent pressure levels and facilitating contaminant removal 4.

Installation and Compatibility

Proper installation of the Cummins 5335924 Breather Tube is crucial for its effective operation. It is designed for specific engine models, ensuring a seamless fit and function. Following manufacturer guidelines for installation ensures optimal performance from this component.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 5335924 Breather Tube is vital for its continued optimal performance. This includes regular inspections for wear or damage and cleaning to remove accumulated contaminants. Common issues such as blockages or leaks can be addressed through troubleshooting steps like cleaning or replacement, as necessary.

Safety Considerations

When handling and installing the Cummins 5335924 Breather Tube, adhering to safety protocols is important to prevent accidents and ensure correct component function. This includes wearing appropriate personal protective equipment and ensuring the engine is off and cool before beginning any work. Following these safety measures maintains a safe working environment.

Environmental Impact

The use of the Cummins 5335924 Breather Tube contributes to reduced emissions and enhanced fuel efficiency. By ensuring optimal engine operation, this component minimizes the environmental impact of commercial trucks. Efficient engine operation leads to lower emissions and better fuel economy, important factors in reducing the overall environmental footprint of transportation 5.

Cummins Overview

Cummins Inc. is a renowned company in the commercial truck industry, known for its wide range of products and strong reputation. With a history of innovation and quality, Cummins has become a trusted name among truck manufacturers and operators. The company’s product range includes engines, filtration systems, and other components designed to enhance the performance and reliability of commercial vehicles.

Role of Part 5335924 Breather Tube in Engine Systems

The Cummins 5335924 Breather Tube is crucial for maintaining the health and efficiency of engine systems, particularly in relation to the crankcase breather system.

In the crankcase breather system, the breather tube facilitates the release of gases that accumulate within the crankcase. These gases, which include a mixture of air, fuel vapors, and combustion byproducts, are a natural byproduct of the engine’s operation. The breather tube allows these gases to escape, preventing a buildup of pressure within the crankcase. This pressure relief is important for maintaining the integrity of engine seals and gaskets, as excessive pressure can lead to leaks and reduced engine performance.

Additionally, the breather tube is often connected to an air filter or a PCV (Positive Crankcase Ventilation) system. This connection ensures that the expelled gases are either filtered or recirculated back into the intake system, where they can be burned again in the combustion chamber. This not only helps in reducing emissions but also improves fuel efficiency by ensuring that any unburned fuel is utilized.

The efficient functioning of the breather tube is also integral to the overall lubrication system of the engine. By maintaining a stable pressure within the crankcase, the breather tube helps ensure that oil does not become aerated. Aerated oil can lead to reduced lubrication efficiency, potentially causing increased wear on engine components.

In summary, the Cummins 5335924 Breather Tube plays a significant role in the effective operation of the crankcase breather system, contributing to pressure management, emission control, and lubrication system stability.

Conclusion

The Cummins 5335924 Breather Tube is a critical component in the maintenance and operation of commercial truck engines. Its role in pressure regulation, ventilation, and contaminant removal is essential for engine efficiency, longevity, and environmental impact reduction. Proper installation, maintenance, and adherence to safety protocols are vital for maximizing the benefits of this component.

-

Haoran Hu, Rudy Smaling, Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Michael Hilgers. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Michael Hilgers. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

A. J. Wharton. Diesel Engines. Butterworth-Heinemann Ltd, 1991.

↩ -

Michael Hilgers. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.