This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

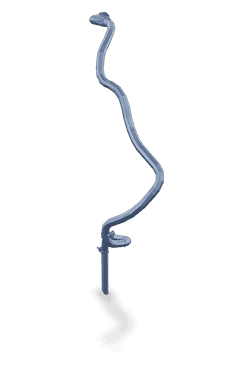

The Cummins 4359966 Breather Tube is a component designed for use in commercial trucks. It serves a specific function within the engine system, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and significance is important for maintaining the health and performance of the truck’s engine.

Basic Concepts of Breather Tubes

A breather tube is a component found in engine systems that allows for the release of pressure and the exchange of air within the crankcase 1. It operates on the principle of maintaining a balanced pressure environment within the engine, which is crucial for the proper functioning of various engine components. By allowing air to enter and exit the crankcase as needed, the breather tube helps to prevent the buildup of pressure that could lead to leaks or other issues.

Purpose of the Cummins 4359966 Breather Tube

This Cummins part plays a role in the operation of a truck by facilitating the release of pressure within the engine’s crankcase. This function is important for maintaining engine health and performance. By ensuring that pressure does not build up excessively, the breather tube helps to protect engine components from damage and contributes to the smooth operation of the engine.

Key Features

The Cummins 4359966 is designed with specific features that enhance its effectiveness and durability. These include a robust construction that can withstand the demands of commercial truck operation, as well as a design that ensures efficient pressure release and air exchange within the crankcase.

Benefits of Using the Cummins 4359966 Breather Tube

Using this part offers several advantages. These include improved engine efficiency due to balanced crankcase pressure, reduced maintenance needs as a result of its durable construction, and enhanced longevity of engine components by preventing pressure-related damage.

Installation Considerations

Proper installation of the Cummins 4359966 is important to ensure optimal performance and compatibility with the truck’s engine system. Installation should follow manufacturer guidelines to ensure that the breather tube is securely fitted and functions as intended within the engine system.

Troubleshooting Common Issues

Common issues associated with breather tubes can include blockages or leaks. Symptoms of these problems may include unusual engine noises or decreased performance. Potential causes can range from debris accumulation to physical damage. Recommended solutions involve inspecting the breather tube for obstructions or damage and performing necessary cleaning or repairs.

Maintenance Tips

Routine maintenance practices for the Cummins 4359966 can help prolong its service life and maintain engine efficiency. These practices include regular inspections for signs of wear or damage, cleaning the breather tube to remove any accumulated debris, and ensuring that it remains securely fitted within the engine system.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. The company has a history of innovation and commitment to providing solutions that meet the needs of its customers, making it a trusted name in the industry 2.

Cummins Breather Tube 4359966 Compatibility

The Cummins Breather Tube part number 4359966 is designed to fit seamlessly with various engine models, ensuring efficient ventilation and pressure regulation. This part is crucial for maintaining the optimal performance and longevity of the engine by allowing the escape of gases and preventing the buildup of pressure within the engine’s crankcase.

ISV (Nissan) Engines

The Cummins Breather Tube 4359966 is compatible with the ISV (Intelligent Systems Vehicle) engines manufactured by Nissan. This compatibility ensures that the breather tube integrates smoothly with the engine’s design, providing reliable ventilation and pressure management. The breather tube’s design aligns with the specific requirements of the ISV engines, ensuring that it fits perfectly and functions as intended.

Role of Part 4359966 Breather Tube in Engine Systems

The Part 4359966 Breather Tube is an essential component in the arrangement of an engine’s crankcase breather system. It facilitates the release of gases that accumulate within the crankcase, ensuring that the internal pressure remains balanced. This is achieved by allowing these gases, which consist of a mixture of air, fuel vapors, and combustion byproducts, to escape rather than build up.

In the crankcase breather system, the breather tube is connected to the crankcase, which houses the crankshaft and connecting rods. As the engine operates, the reciprocating motion of the pistons creates pressure fluctuations within the crankcase. The breather tube provides a pathway for these pressure changes to be managed effectively.

Additionally, the breather tube often connects to a PCV (Positive Crankcase Ventilation) valve or a similar device. This connection ensures that the expelled gases are not simply released into the atmosphere but are instead routed back into the intake manifold. This process not only helps in maintaining optimal engine performance but also reduces emissions by ensuring that these gases are burned again during the combustion process.

The efficient functioning of the breather tube is integral to the overall health of the engine. It prevents the buildup of sludge and contaminants within the crankcase, which can otherwise lead to decreased engine efficiency and potential damage over time. Furthermore, by maintaining a stable pressure environment, the breather tube contributes to the longevity and reliability of the engine components.

Conclusion

The Cummins 4359966 Breather Tube is a vital component in the engine system of commercial trucks, ensuring efficient pressure management and ventilation within the crankcase. Its robust design and compatibility with various engine models make it a reliable choice for maintaining engine health and performance. Regular maintenance and proper installation are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.