This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

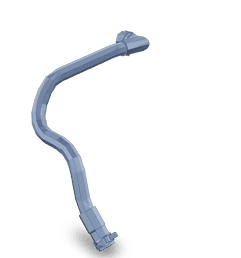

The Cummins 4359685 Breather Tube is a component designed for use in commercial truck engines. Its purpose is to facilitate the release of pressure and ventilation within the engine system, contributing to the overall efficiency and reliability of the engine. This part is integral to maintaining optimal engine performance by ensuring that pressure levels are regulated and that contaminants are minimized within the engine’s crankcase.

Basic Concepts of Breather Tubes

A breather tube is a component found in engine systems that allows for the release of pressure and the exchange of air within the crankcase. Its operation is based on the principle of pressure equalization; as the engine operates, it generates pressure within the crankcase. The breather tube provides a pathway for this pressure to be released, preventing buildup that could lead to leaks or damage. Additionally, it allows for the ventilation of the crankcase, which helps to remove contaminants and moisture that may accumulate during engine operation 1.

Purpose of the Cummins 4359685 Breather Tube

The Cummins 4359685 Breather Tube plays a specific role in the engine system by regulating pressure and facilitating ventilation. It ensures that the crankcase maintains a balanced pressure, which is vital for the proper functioning of the engine. By allowing air to flow in and out of the crankcase, it helps to remove contaminants and moisture, which can otherwise lead to sludge formation and decreased engine performance. This breather tube is designed to work in conjunction with other engine components to maintain an optimal operating environment 2.

Key Features

The Cummins 4359685 Breather Tube is characterized by several key features that enhance its functionality. It is constructed from durable materials that can withstand the high temperatures and pressures within the engine system. The design includes specific elements that ensure efficient pressure release and ventilation. Additionally, it may incorporate unique characteristics such as filters or baffles to further enhance its performance and protect the engine from contaminants 3.

Benefits of Using the Cummins 4359685 Breather Tube

Incorporating the Cummins 4359685 Breather Tube into truck engines offers several advantages. It contributes to improved engine performance by ensuring that pressure levels are maintained within safe limits and that the crankcase is properly ventilated. This can lead to increased engine longevity, as the risk of damage from pressure buildup or contamination is reduced. Additionally, the breather tube enhances the reliability of the engine, providing consistent performance over time.

Installation and Integration

To properly install and integrate the Cummins 4359685 Breather Tube into a truck’s engine system, follow these steps:

- Locate the designated mounting point on the engine.

- Ensure the engine is cool and the system is depressurized.

- Align the breather tube with the mounting point and secure it in place using the provided fasteners.

- Connect any necessary hoses or fittings to complete the integration.

- Verify that the breather tube is properly installed and that there are no leaks in the system.

Troubleshooting Common Issues

Frequent problems associated with breather tubes can include blockages, leaks, or contamination. Potential causes may be debris accumulation, wear and tear, or improper installation. Recommended solutions include regular inspection for blockages, ensuring all connections are secure, and cleaning or replacing the breather tube if contamination is detected.

Maintenance Tips

To ensure the longevity and efficiency of the Cummins 4359685 Breather Tube, consider the following maintenance practices:

- Inspect the breather tube regularly for signs of wear, damage, or contamination.

- Clean the breather tube and its components as needed to remove any accumulated debris.

- Follow the manufacturer’s recommended inspection and maintenance schedules to ensure optimal performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines. The company’s product range includes a variety of engine solutions designed to meet the diverse needs of commercial vehicle operators, ensuring efficiency, durability, and compliance with industry standards.

Conclusion

The Cummins 4359685 Breather Tube is a vital component in the engine systems it is designed for, ensuring proper ventilation and preventing pressure build-up, which is essential for the longevity and efficiency of the engine. Its role in maintaining optimal engine performance by regulating pressure and facilitating ventilation cannot be overstated. Regular maintenance and proper installation are key to ensuring the breather tube functions effectively, contributing to the overall reliability and performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.