This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbo Coolant Supply Tube, identified by part number 4325404, is a component manufactured by Cummins, a leader in the automotive and heavy-duty truck industry. This tube is integral to the cooling system of heavy-duty truck engines, ensuring the turbocharger operates within optimal temperature ranges. Cummins is renowned for its commitment to innovation and quality, making this component a reliable choice for maintaining engine performance and longevity 1.

Function and Operation

The Turbo Coolant Supply Tube facilitates the flow of coolant to the turbocharger within the engine cooling system. Its operation involves directing coolant from the engine’s cooling system to the turbocharger, where it absorbs excess heat. This process helps maintain the turbocharger’s temperature within specified limits, ensuring efficient operation and preventing overheating. The tube is designed to handle the pressures and temperatures associated with heavy-duty engine operations, contributing to the overall stability of the cooling system 2.

Purpose of the Turbo Coolant Supply Tube

The primary role of the Turbo Coolant Supply Tube is to support the efficient operation of the turbocharger by regulating its temperature. By maintaining optimal turbocharger temperature, the tube contributes to engine efficiency and performance. This is particularly important in heavy-duty applications where the engine operates under demanding conditions, and temperature management is crucial for sustained performance and reliability 3.

Key Features

The Turbo Coolant Supply Tube is characterized by several key features that enhance its functionality and durability. It is typically made from high-quality materials resistant to corrosion and high temperatures, ensuring longevity and reliable performance. The design of the tube includes precise fittings and connections that integrate seamlessly with other engine components, facilitating easy installation and maintenance. Additionally, the tube is engineered to withstand the dynamic pressures within the cooling system, ensuring consistent coolant flow.

Benefits

The advantages of using the Turbo Coolant Supply Tube include improved engine longevity, enhanced performance, and reliable operation under various conditions. By effectively managing turbocharger temperature, the tube helps prevent overheating, which can lead to engine damage. This results in more consistent engine performance and reduced maintenance requirements. Furthermore, the tube contributes to overall engine efficiency, potentially improving fuel economy and reducing emissions.

Installation and Compatibility

Proper installation of the Turbo Coolant Supply Tube is vital for ensuring its effective operation and integration within the engine system. Installation procedures should follow manufacturer guidelines to ensure correct fitting and sealing. Compatibility with specific Cummins engine models is an important consideration, as the tube is designed to meet the unique requirements of these engines. Ensuring the correct part is used for the specific engine model will help maintain optimal performance and reliability.

Maintenance and Troubleshooting

Regular maintenance of the Turbo Coolant Supply Tube is important for ensuring continued efficient operation. This includes checking for leaks, inspecting connections, and ensuring the tube is free from obstructions. Common issues may include coolant leaks or reduced flow, which can be addressed by inspecting the tube and connections for wear or damage. Troubleshooting steps may involve replacing worn components or adjusting connections to ensure proper coolant flow.

Performance Impact

The Turbo Coolant Supply Tube plays a role in overall engine performance by helping to maintain optimal turbocharger temperature. This contributes to more efficient engine operation, potentially improving fuel efficiency and reducing emissions. By ensuring the turbocharger operates within its designed temperature range, the tube helps sustain engine power and responsiveness, particularly under demanding conditions.

Safety Considerations

When handling and installing the Turbo Coolant Supply Tube, it is important to follow safety protocols to prevent accidents and ensure proper function. This includes wearing appropriate personal protective equipment, ensuring the engine is cool before beginning work, and following manufacturer guidelines for installation. Proper handling and installation will help prevent leaks and ensure the tube functions as intended, contributing to safe and reliable engine operation.

Environmental Impact

The Turbo Coolant Supply Tube contributes to reducing emissions and enhancing the environmental performance of heavy-duty trucks by supporting efficient engine operation. By helping to maintain optimal turbocharger temperature, the tube ensures the engine operates more efficiently, which can lead to lower fuel consumption and reduced emissions. This aligns with broader efforts to improve the environmental performance of heavy-duty vehicles.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history spanning over a century, Cummins is committed to innovation and sustainability in the automotive industry. The company’s product range includes engines for on-highway and off-highway applications, as well as components and systems that enhance engine performance and efficiency. Cummins’ dedication to quality and innovation is evident in its comprehensive lineup of products, including the Turbo Coolant Supply Tube.

Turbo Coolant Supply Tube for Cummins Engines

The Turbo Coolant Supply Tube, identified by part number 4325404, is a critical component in the cooling system of certain Cummins engines. This part is integral in maintaining the optimal operating temperature of the turbocharger by ensuring a steady flow of coolant.

ISV (Nissan) Engines

For the ISV engines, which are powered by Cummins, the Turbo Coolant Supply Tube is designed to integrate seamlessly with the engine’s cooling architecture. This tube facilitates the transfer of coolant from the engine’s radiator to the turbocharger, ensuring that the turbocharger operates within its specified temperature range. This is particularly important in high-performance or heavy-duty applications where the turbocharger can experience significant thermal stress.

The Turbo Coolant Supply Tube is engineered to withstand the high pressures and temperatures associated with the engine’s operation. Its robust construction ensures durability and reliability, which are essential for maintaining the performance and longevity of the engine.

By ensuring that the turbocharger is adequately cooled, the Turbo Coolant Supply Tube helps to prevent overheating, which can lead to reduced efficiency and potential damage to the turbocharger and engine components. This part is a testament to Cummins’ commitment to providing high-quality, reliable components for their engines.

Role of Part 4325404 Turbo Coolant Supply Tube in Engine Systems

The Turbo Coolant Supply Tube (part 4325404) is an essential component in the thermal management system of turbocharged engines. It is responsible for delivering coolant to the turbocharger, ensuring optimal operating temperatures are maintained.

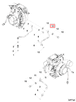

Integration with Turbocharger Plumbing

In the context of turbocharger plumbing, the Turbo Coolant Supply Tube connects to the turbocharger’s coolant passages. This connection allows coolant to flow through the turbocharger, absorbing excess heat generated during high-performance operations. The efficient circulation of coolant helps in maintaining the integrity and performance of the turbocharger, preventing overheating and potential damage.

Interaction with Turbocharger Coolant Drain Tube

The Turbo Coolant Supply Tube works in conjunction with the Turbocharger Coolant Drain Tube to create a closed-loop coolant system. After the coolant absorbs heat from the turbocharger, it is directed back into the engine’s cooling system via the drain tube. This continuous circulation ensures that the turbocharger remains within safe operating temperatures, enhancing its longevity and efficiency.

Coordination with Turbo Coolant Drain Tube

Similarly, the Turbo Coolant Supply Tube interfaces with the Turbo Coolant Drain Tube to manage the outflow of heated coolant. This drain tube facilitates the removal of coolant that has absorbed heat, allowing fresh, cool coolant to be supplied by the supply tube. This dynamic ensures a consistent temperature regulation within the turbocharger, supporting sustained high-performance operation.

Overall System Functionality

By effectively supplying coolant to the turbocharger, part 4325404 plays a significant role in the overall thermal management of the engine system. Its integration with other components like the turbocharger plumbing and drain tubes creates a robust coolant circulation system. This system is vital for maintaining the turbocharger’s performance and reliability under various operating conditions.

Conclusion

The Turbo Coolant Supply Tube (part 4325404) is a critical component in the thermal management system of turbocharged engines. It ensures the turbocharger operates within optimal temperature ranges, contributing to engine efficiency, performance, and longevity. Proper installation, maintenance, and understanding of its role within the engine system are essential for maximizing the benefits of this Cummins part.

References

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.