This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

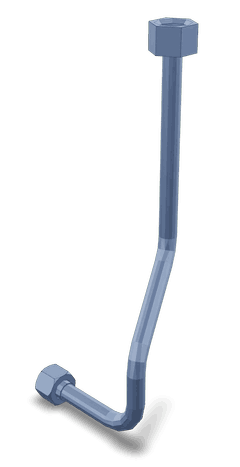

The Scavenge Outlet Tube, part number 4314289, is a component manufactured by Cummins, a prominent name in the automotive and heavy-duty truck industry. This tube is crucial for the lubrication system in heavy-duty truck engines, enhancing engine efficiency and reliability.

Basic Concepts and Functionality

The Scavenge Outlet Tube is vital to the engine’s lubrication system. It removes oil from the engine’s crankcase, ensuring efficient oil circulation. This interaction with the oil pan and other lubrication components facilitates smooth engine operation by maintaining adequate oil levels and pressure 1.

Purpose of the Scavenge Outlet Tube

The primary role of the Scavenge Outlet Tube is to support the engine’s lubrication system by ensuring efficient oil circulation. It maintains optimal lubrication of engine components, reducing wear and tear, enhancing performance, and prolonging engine life. By facilitating proper oil flow, it contributes to the engine’s overall lubrication strategy 2.

Key Features

The Scavenge Outlet Tube is designed with specific features to enhance performance and durability. Constructed from high-quality materials, it withstands harsh engine conditions. Its design ensures a secure fit within the lubrication system, promoting efficient oil flow and reducing leak risks. Additionally, it may include features for easy installation and maintenance 3.

Benefits

Incorporating the Scavenge Outlet Tube into an engine’s lubrication system offers several advantages. It improves engine reliability by ensuring consistent oil circulation, leading to reduced maintenance needs. Well-lubricated engines are less prone to wear and damage. Furthermore, the efficient operation of the lubrication system supported by this tube enhances overall engine efficiency 4.

Installation and Integration

Installing the Scavenge Outlet Tube requires careful consideration to ensure proper integration into the engine’s lubrication system. This may involve preparing the installation site, ensuring compatibility with existing components, and making necessary adjustments to secure the tube. Proper installation is key to ensuring the tube functions as intended within the engine system 5.

Troubleshooting and Maintenance

Common issues with the Scavenge Outlet Tube may include blockages or leaks, affecting the engine’s lubrication system efficiency. Diagnostic methods for identifying these issues may involve visual inspections and testing oil flow. Maintenance practices to ensure longevity and optimal performance include regular inspections, cleaning, and, if necessary, replacement of the tube to prevent adverse effects on engine performance 6.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industry for producing high-quality, reliable components. The company’s extensive product range and commitment to innovation and customer satisfaction have made it a preferred choice for professionals in the industry 7.

Conclusion

The Scavenge Outlet Tube (part 4314289) is a vital component in the lubrication systems of heavy-duty truck engines. Its role in maintaining efficient oil circulation and supporting engine performance and reliability underscores its importance in engine maintenance and operation.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Maclaurin, B. (2018). High Speed Off-Road Vehicles. Wiley.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISB5.9 CM2880 B140. Bulletin Number 5411230.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISB5.9 CM2880 B140. Bulletin Number 5411230.

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.