This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

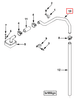

The Cummins 3930709 Breather Tube is a component designed for use in heavy-duty truck engines. Its role is to facilitate the release of gases and vapors from the engine’s crankcase, contributing to the overall maintenance and operation of the vehicle. Proper functioning of this part is significant for ensuring the engine operates efficiently and remains in optimal condition over time 1.

Basic Concepts of Breather Tubes

Breather tubes are integral components within an engine system, designed to allow the escape of gases and vapors that accumulate within the crankcase. These tubes operate on the principle of pressure equalization, ensuring that the internal pressure within the crankcase does not exceed safe levels. The design and operation of breather tubes are based on maintaining a balance between the internal and external pressures of the engine, which helps in preventing damage and ensuring smooth operation 2.

Purpose of the Cummins 3930709 Breather Tube

The Cummins 3930709 Breather Tube serves a specific role in the operation of a truck by allowing the release of gases and vapors from the engine’s crankcase. This function is vital for maintaining engine health and performance, as it helps in preventing the buildup of pressure that could lead to leaks or other forms of engine damage. By facilitating the escape of these gases, the breather tube contributes to the longevity and efficiency of the engine.

Key Features

The Cummins 3930709 Breather Tube is characterized by several key features that distinguish it from other breather tubes. These include its material composition, which is designed to withstand the harsh conditions within an engine environment, and its design elements that ensure efficient operation. Unique characteristics of this breather tube may include specific fittings or connections that enhance its functionality and compatibility with Cummins engines.

Benefits

Using the Cummins 3930709 Breather Tube offers several benefits. These include improved engine longevity, as the breather tube helps in maintaining optimal crankcase pressure and preventing damage. Enhanced performance is another benefit, as the efficient release of gases and vapors contributes to the overall efficiency of the engine. Additionally, the breather tube’s design ensures reliability in various operating conditions, making it a valuable component for heavy-duty truck engines.

Installation and Compatibility

Proper installation of the Cummins 3930709 Breather Tube is crucial for ensuring its effectiveness and compatibility with different truck models and engine types. Guidelines for installation should be followed to ensure that the breather tube is securely fitted and functions as intended. Specific requirements or considerations may include ensuring the correct orientation and connection to the engine’s crankcase and other components.

Troubleshooting and Maintenance

Common issues related to breather tubes can often be traced back to improper installation, blockages, or wear and tear. Regular maintenance, including inspection for signs of damage or blockage, can help in ensuring optimal performance. Signs that may indicate the need for replacement or repair include unusual noises from the engine, decreased performance, or visible damage to the breather tube itself.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its commitment to producing high-quality automotive components. With a rich history and a reputation for excellence, Cummins has consistently delivered reliable and efficient parts for heavy-duty trucks and other vehicles. The company’s dedication to quality and innovation is evident in its wide range of products, including the Cummins 3930709 Breather Tube 3.

Role of Part 3930709 Breather Tube in Engine Systems

The 3930709 Breather Tube is an essential component in maintaining the health and efficiency of engine systems. It is specifically designed to work in conjunction with the crankcase and valve cover breather kit to manage the pressure and ventilation within these systems.

Integration with the Crankcase

In the crankcase, the breather tube plays a significant role in pressure equalization. As the engine operates, it generates gases and vapors that need to be expelled to prevent a buildup of pressure. The breather tube provides a pathway for these byproducts to escape, ensuring that the crankcase maintains a stable pressure environment. This stability is vital for the proper lubrication and cooling of moving parts within the crankcase, contributing to the overall longevity and performance of the engine.

Function within the Valve Cover Breather Kit

When integrated into a valve cover breather kit, the breather tube facilitates the removal of contaminants and moisture that accumulate in the valve cover. This is particularly important in preventing the formation of sludge, which can lead to decreased engine efficiency and potential damage. The breather tube, as part of the kit, ensures that the valve cover remains clean and dry, optimizing the operation of the valve train and associated components.

Overall System Contribution

By effectively managing pressure and ventilation in both the crankcase and valve cover, the breather tube contributes to a more stable and efficient engine operation. It aids in the reduction of wear on engine components, enhances lubrication efficiency, and helps in maintaining optimal engine performance over time. The breather tube’s role in these systems underscores the importance of proper ventilation and pressure management in engine design and maintenance.

Conclusion

The Cummins 3930709 Breather Tube plays a crucial role in the maintenance and efficiency of heavy-duty truck engines. Its design and functionality are tailored to ensure optimal engine performance by managing crankcase pressure and facilitating the removal of contaminants. Proper installation, regular maintenance, and understanding its role within the engine system are key to leveraging the full benefits of this Cummins part.

-

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ -

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Cummins Inc. Company Overview. Available at: Cummins Official Website (Accessed: March 2024).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.