This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

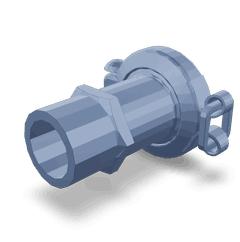

The Cummins 3394952 Tube Connector is a component designed for use in commercial trucks. It serves a specific function within the truck’s fluid systems, facilitating the connection between tubes. A tube connector, in general, is a device that joins two or more tubes together, ensuring a secure and leak-free connection. This is vital for the proper operation of fluid systems, which include fuel, hydraulic, and coolant systems among others 1.

Basic Concepts of Tube Connectors

Tube connectors are engineered to create reliable connections between tubes in fluid systems. They are typically made from materials that can withstand the pressures and temperatures of the system they serve. The design of a tube connector often includes features that ensure a proper seal, such as O-rings or gaskets, and mechanisms to secure the connection, like threads or clamps. The integrity of the connection is paramount to prevent leaks and ensure the efficient transfer of fluids 2.

Purpose of the 3394952 Tube Connector

This Cummins part is integral to the operation of a truck’s fluid systems. It is designed to connect tubes within systems such as the fuel, hydraulic, or coolant circuits. By providing a secure connection, it contributes to the overall functionality and efficiency of these systems, ensuring that fluids are transported without leakage or loss of pressure.

Key Features

The 3394952 boasts several key features that enhance its performance. Its design is tailored to the specific requirements of commercial truck applications, with a material composition that offers durability and resistance to the operating conditions. The connection type, whether threaded or push-fit, is chosen for its reliability and ease of use. Additionally, the connector is compatible with a range of tube sizes and types, making it a versatile component in various fluid systems.

Benefits

Using this part offers several advantages. It provides improved sealing, which is crucial for maintaining system integrity. The ease of installation reduces downtime during maintenance procedures. Its durability under high pressure or temperature ensures long-term reliability. Furthermore, the connector’s resistance to corrosion or wear contributes to the longevity of the truck’s fluid systems, reducing the need for frequent replacements.

Installation and Usage

Proper installation of the 3394952 is key to its performance. This involves preparing the tubes for connection, adhering to torque specifications for threaded connections, and using any special tools or procedures as required. Best practices for installation include ensuring that all surfaces are clean and free of debris, and that the connector is aligned correctly to prevent stress on the connection.

Troubleshooting and Maintenance

Tube connectors, including the 3394952, may encounter issues such as leaks, corrosion, or connection failure over time. Troubleshooting these problems involves inspecting the connector for signs of wear or damage, checking for proper alignment and torque, and ensuring that all sealing elements are in good condition. Regular maintenance, such as cleaning and inspecting the connector, can help prolong its life. Replacement should be considered if there are signs of significant wear or if the connector no longer provides a secure seal.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products and commitment to quality and innovation. The company has a history of producing reliable automotive components, and the 3394952 is a testament to its dedication to excellence in manufacturing. Cummins’ reputation is built on the performance and durability of its products, which are designed to meet the demanding requirements of commercial truck applications.

Tube Connector 3394952 in Cummins Engines

The Tube Connector part number 3394952 is a critical component in several Cummins engine models, ensuring the seamless transfer of fluids and gases within the engine system. This part is designed to maintain the integrity of the engine’s fluid pathways, preventing leaks and ensuring optimal performance.

G8.3 Engines

In the G8.3 engine series, the Tube Connector 3394952 is integral to the engine’s cooling and exhaust systems. It facilitates the connection between various tubes and hoses, ensuring that coolant and exhaust gases are efficiently managed. This part is essential for maintaining the engine’s operational temperature and ensuring that exhaust gases are properly expelled, contributing to both performance and emissions control.

Grouping of Engines

The Tube Connector 3394952 is also utilized in other Cummins engine models that share similar design and operational principles with the G8.3 series. These engines often require precise fluid and gas management to maintain efficiency and reliability. By using the same Tube Connector, Cummins ensures consistency and compatibility across different engine models, simplifying maintenance and repair processes.

Role of Part 3394952 Tube Connector in Engine Systems

The 3394952 Tube Connector is an essential component in the integration and functionality of various engine systems. Its primary role is to facilitate secure and efficient connections between different parts, ensuring optimal performance and reliability.

Integration with the Module

In engine systems, the module often serves as the brain, controlling various functions and parameters. The 3394952 Tube Connector plays a significant role in linking the module to other critical components. It ensures that the module receives accurate data from sensors and delivers precise commands to actuators. This connection is vital for the module to monitor and adjust engine performance in real-time.

Connection to the Fuel Control System

The fuel control system is responsible for regulating the fuel supply to the engine. The 3394952 Tube Connector is used to connect the fuel lines to the fuel control unit. This ensures a consistent and controlled flow of fuel, which is essential for maintaining engine efficiency and power output. The connector’s design helps prevent leaks and ensures that the fuel system operates under the correct pressure conditions.

Interface with the Valve

Valves in engine systems control the flow of fluids, such as fuel or coolant. The 3394952 Tube Connector is employed to link the valve to the respective fluid lines. This connection is important for the valve to open and close at the right times, ensuring that the engine receives the necessary fluids at optimal intervals. The connector’s robust construction helps withstand the high pressures and temperatures often encountered in engine environments.

Link to the Pressure Regulator

The pressure regulator maintains the desired pressure levels within the engine system. The 3394952 Tube Connector is used to attach the regulator to the fluid lines. This ensures that the regulator can monitor and adjust pressure as needed, contributing to the overall stability and performance of the engine. The connector’s precise fitment helps maintain the integrity of the pressure regulation system, preventing fluctuations that could affect engine operation.

Conclusion

The Cummins 3394952 Tube Connector plays a crucial role in the efficient operation of commercial truck fluid systems. Its design and features ensure secure, leak-free connections that are vital for the proper functioning of fuel, hydraulic, and coolant systems. The benefits of using this part include improved sealing, ease of installation, durability under high pressure or temperature, and resistance to corrosion or wear. Proper installation, regular maintenance, and timely troubleshooting are essential for maximizing the performance and longevity of the 3394952 Tube Connector in commercial truck applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.