This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3254292 Manifold Pressure Tube, manufactured by Cummins, is a critical component in the operation of commercial trucks. Cummins, a well-established name in the automotive industry, is renowned for its high-quality engine components. This part is designed to enhance the performance and efficiency of truck engines, playing a significant role in maintaining optimal engine operation.

Basic Concepts of Manifold Pressure Tubes

A Manifold Pressure Tube is a component within an engine system that measures the pressure of the air-fuel mixture entering the engine’s cylinders. This measurement is essential for the engine control unit (ECU) to adjust the fuel injection and ignition timing, ensuring efficient combustion. The Manifold Pressure Tube operates by connecting to the intake manifold and transmitting pressure readings to the ECU, thereby contributing to the engine’s overall performance 1.

Purpose of the 3254292 Manifold Pressure Tube

The 3254292 Manifold Pressure Tube is specifically designed to enhance the operation of commercial trucks. It plays a role in the engine system by providing accurate pressure readings, which the ECU uses to optimize fuel delivery and ignition timing. This optimization leads to improved engine efficiency and performance, ensuring that the truck operates smoothly under various conditions.

Key Features

The 3254292 Manifold Pressure Tube boasts several key features that enhance its functionality. It is constructed from durable materials, ensuring longevity and reliability. The design includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, the tube is engineered to withstand the high pressures and temperatures within the engine compartment, making it suitable for demanding commercial truck applications.

Benefits

The 3254292 Manifold Pressure Tube offers several benefits. It contributes to improved engine performance by providing accurate pressure readings that allow the ECU to make precise adjustments. This results in better fuel efficiency and reduced emissions. The tube’s durable construction ensures long-term reliability, minimizing the need for frequent replacements. Furthermore, its robust design enhances the overall durability and performance of the truck’s engine system.

Installation Process

Installing the 3254292 Manifold Pressure Tube requires careful attention to detail. Begin by ensuring the engine is cool and the vehicle is parked on a level surface. Use the appropriate tools to disconnect the old tube from the intake manifold. Carefully install the new tube, ensuring all connections are secure and leak-free. Double-check all fittings to confirm a proper installation. Finally, start the engine and monitor the pressure readings to ensure the tube is functioning correctly.

Troubleshooting Common Issues

Common issues with Manifold Pressure Tubes include leaks and malfunctions. If a leak is detected, inspect the connections and fittings for any signs of damage or wear. Tighten any loose connections and replace any damaged components. Malfunctions may be indicated by inconsistent pressure readings. In such cases, verify the tube’s installation and ensure there are no obstructions or debris affecting its operation. If problems persist, consult a professional technician for further diagnosis.

Maintenance Tips

To ensure the longevity and optimal performance of the 3254292 Manifold Pressure Tube, regular maintenance is recommended. Inspect the tube and its connections at routine intervals for any signs of wear or damage. Clean the tube and surrounding components to remove any buildup that could affect its operation. Additionally, ensure that the tube is properly secured and that all connections are tight to prevent leaks and maintain accurate pressure readings.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation within the commercial truck industry for producing high-quality, reliable components. The company’s product offerings include a wide range of engines and engine components, all designed to meet the demanding requirements of commercial applications. Cummins’ commitment to innovation and excellence has made it a trusted name in the industry.

Manifold Pressure Tube (Part 3254292) in Cummins Engines

The Manifold Pressure Tube, identified by part number 3254292, is a critical component in various Cummins engines, ensuring accurate measurement of manifold pressure. This part is integral to the engine’s performance and efficiency, as it facilitates the transmission of pressure data from the intake manifold to the engine control unit (ECU).

N14 MECHANICAL

In the N14 MECHANICAL engine, the Manifold Pressure Tube is designed to fit precisely within the engine’s intake system. This tube connects the intake manifold to the pressure sensor, ensuring that the ECU receives accurate readings of the manifold pressure. The precise fitment of this part is crucial for maintaining optimal engine performance, as it directly impacts the air-fuel mixture and overall engine operation.

The Manifold Pressure Tube in the N14 MECHANICAL engine is engineered to withstand the high temperatures and pressures typical of diesel engines. Its robust construction ensures durability and reliability, contributing to the engine’s longevity and efficiency. Proper installation and maintenance of this component are essential to prevent any disruptions in the pressure readings, which could lead to suboptimal engine performance or potential damage.

Role of Part 3254292 Manifold Pressure Tube in Engine Systems

The 3254292 Manifold Pressure Tube is an integral component in the efficient operation of various engine systems. It is primarily responsible for the precise measurement and regulation of manifold pressure, which is essential for optimal engine performance.

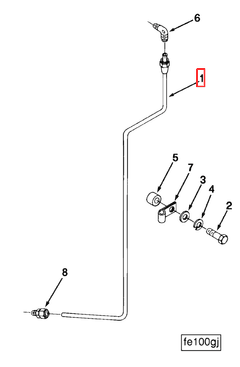

Integration with Engine Block and Manifold

The Manifold Pressure Tube interfaces directly with the engine block and the intake manifold. It is connected to the manifold via secure fittings, ensuring a leak-free passage for the pressure readings. This connection allows the tube to accurately transmit pressure data from the manifold to the Air Fuel Control (AFC) system.

Interaction with Air Fuel Control (AFC) System

The AFC system relies on the data provided by the Manifold Pressure Tube to adjust the air-fuel mixture. The tube sends real-time pressure readings to the AFC, enabling it to make precise adjustments to fuel delivery and air intake. This ensures that the engine operates within its optimal performance range, enhancing both efficiency and power output.

Coordination with Fuel Plumbing and Tubing

In conjunction with the fuel plumbing and tubing, the Manifold Pressure Tube plays a significant role in maintaining consistent fuel pressure. The tube’s accurate pressure readings help in fine-tuning the fuel delivery system, ensuring that the correct amount of fuel is supplied under varying engine loads and conditions.

Role in Overall Plumbing System

The Manifold Pressure Tube is a key element in the overall plumbing system of the engine. It works in tandem with other plumbing components to ensure that all systems—fuel, air, and pressure—are in harmony. This integration is vital for the smooth operation of the engine, preventing issues such as fuel starvation or over-rich conditions.

Contribution to Engine Management

By providing accurate manifold pressure data, the 3254292 Manifold Pressure Tube contributes to the overall engine management system. It helps in maintaining the correct air-fuel ratio, which is essential for efficient combustion, reduced emissions, and improved engine longevity.

Conclusion

In summary, the 3254292 Manifold Pressure Tube is a vital link in the chain of components that ensure the engine operates at peak performance. Its accurate pressure readings are fundamental to the proper functioning of the AFC system, fuel plumbing, and the overall engine management system. Proper installation, maintenance, and understanding of its role within the engine system are essential for maximizing the efficiency and longevity of commercial truck engines.

-

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.