This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3252439 Tube Connector is a component designed for use in commercial trucks. It serves a specific function within the truck’s fluid systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is important for maintaining and optimizing the performance of heavy-duty trucks.

Basic Concepts of Tube Connectors

Tube connectors are components used in fluid systems to join tubes and facilitate the transfer of fluids such as fuel, coolant, or hydraulic fluid. They ensure a secure and leak-free connection, which is vital for the proper operation of these systems. In the context of heavy-duty trucks, tube connectors play a role in maintaining the integrity and efficiency of fluid transfer within the vehicle 1.

Purpose of the 3252439 Tube Connector

The 3252439 Tube Connector is designed to connect tubes within the truck’s fluid systems. Its role is to provide a reliable connection point that ensures the smooth and uninterrupted flow of fluids. This connector is integral to maintaining the performance and longevity of the truck’s fluid systems.

Key Features

The 3252439 Tube Connector is constructed from durable materials that can withstand the pressures and temperatures encountered in heavy-duty truck applications. Its design includes features that enhance its performance, such as a secure locking mechanism to prevent disconnection and a smooth interior to minimize flow resistance 2.

Benefits

The use of the 3252439 Tube Connector offers several benefits. It contributes to improved system reliability by providing a secure connection that resists leaks. Its design allows for ease of installation, reducing downtime during maintenance. Additionally, it plays a role in enhancing overall system efficiency by ensuring a consistent flow of fluids 3.

Installation Process

To install the 3252439 Tube Connector, begin by ensuring that the tubes to be connected are clean and free of debris. Align the connector with the tubes and engage the locking mechanism to secure the connection. Tools required may include a wrench for tightening and a cleaning brush for preparing the tubes. Following the manufacturer’s guidelines ensures a proper fit and function.

Maintenance Tips

Regular inspection of the 3252439 Tube Connector is recommended to identify any signs of wear or damage. Cleaning the connector and the surrounding area can prevent buildup that may affect performance. If any issues are detected, such as leaks or corrosion, the connector should be replaced to maintain system integrity.

Troubleshooting Common Issues

Common problems with tube connectors include leaks and corrosion. To address these issues, first, ensure that the connector is properly installed and secured. If leaks persist, inspect for damage or wear that may require replacement. Corrosion can often be mitigated through regular cleaning and the application of protective coatings.

Compatibility and Applications

The 3252439 Tube Connector is designed for use in various truck models and systems, demonstrating its versatility and widespread application within the industry.

Safety Considerations

When working with the 3252439 Tube Connector, it is important to observe safety practices. This includes wearing appropriate personal protective equipment and ensuring that the truck’s fluid systems are depressurized before beginning any work. Following these precautions helps to ensure a safe working environment.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products and commitment to quality. With a history of innovation and excellence, Cummins continues to be a trusted name in the field, providing components that contribute to the efficiency and reliability of commercial vehicles.

Tube Connector 3252439 Compatibility with Cummins Engines

The Tube Connector part number 3252439, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is crucial for maintaining the integrity and functionality of the engine’s cooling system. Here is a detailed look at its compatibility with specific Cummins engines:

K19 Engine

The Tube Connector 3252439 is engineered to integrate perfectly with the K19 engine. This part ensures that the coolant flows efficiently through the engine, preventing overheating and maintaining optimal performance.

L10 MECHANICAL and N14 MECHANICAL Engines

For both the L10 MECHANICAL and N14 MECHANICAL engines, the Tube Connector 3252439 is a vital component. It connects various coolant passages, ensuring that the coolant circulates effectively throughout the engine. This is particularly important in these mechanical engines, where precise coolant management is essential for longevity and reliability.

QSN14 CM876 N103 Engine

The Tube Connector 3252439 also fits the QSN14 CM876 N103 engine. This part is designed to handle the specific demands of this engine model, providing a secure and reliable connection for coolant flow. Its precision engineering ensures that the engine operates at peak efficiency, with minimal risk of coolant leaks or blockages.

By ensuring a proper fit and function, the Tube Connector 3252439 plays a critical role in the overall performance and durability of these Cummins engines.

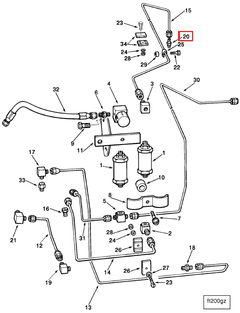

Role of Part 3252439 Tube Connector in Engine Systems

The Tube Connector, identified as part 3252439, is integral to the seamless operation of various engine systems by ensuring secure and efficient fluid transfer. This component is strategically employed in several key areas:

-

Fuel Manifold Integration: The Tube Connector facilitates the connection between the fuel manifold and other fuel system components, allowing for the regulated distribution of fuel to the engine cylinders.

-

Fuel Pump Outlet Connection: It securely attaches to the fuel pump outlet, ensuring a consistent and leak-free transfer of fuel from the pump to the fuel lines.

-

Fuel Supply Plumbing: Within the fuel supply plumbing system, the Tube Connector plays a vital role in linking fuel lines to the fuel supply mounting points, enhancing the reliability of fuel delivery to the engine.

-

Fuel Drain Mounting: The connector is also utilized in the fuel drain system, where it connects to the fuel drain mounting, aiding in the efficient removal of excess fuel or contaminants from the fuel system.

-

Fuel Tubing and EBM Tubing Connections: It is employed to join sections of fuel tubing and EBM (Engine Bay Module) tubing, ensuring a continuous and secure pathway for fuel flow throughout the engine bay.

-

Check Valve Mounting: In systems incorporating check valves, the Tube Connector is used to mount these valves securely, preventing backflow and ensuring unidirectional fuel flow.

-

Fuel Supply Mounting: It connects to fuel supply mounting points, providing a stable and secure attachment for fuel lines, which is essential for maintaining the integrity of the fuel supply system.

-

Plumbing and Gauge Sight Connections: The Tube Connector is also instrumental in linking plumbing components to gauge sight systems, allowing for the monitoring of fuel levels and system pressure, which is crucial for diagnostic and maintenance purposes.

In summary, the Tube Connector (part 3252439) is a versatile and essential component in engine systems, facilitating secure and efficient connections across a variety of fuel system applications.

Conclusion

The Cummins 3252439 Tube Connector is a vital component in the fluid systems of commercial trucks, ensuring secure and efficient fluid transfer. Its durable construction, ease of installation, and compatibility with various Cummins engines make it an essential part for maintaining the performance and reliability of heavy-duty trucks. Regular maintenance and proper installation are key to maximizing the benefits of this connector.

-

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions: Fundamentals, Selection, Design and Application. Springer Vieweg.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.