This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Bleed Tube 3252415, manufactured by Cummins, is a component designed for use in commercial trucks. It plays a role in the truck’s system, contributing to the vehicle’s efficiency and reliability. Understanding its purpose and operation is important for maintaining the truck’s performance.

Basic Concepts of Bleed Tubes

A bleed tube is used in various truck systems to manage the flow of fluids or gases. It allows the release of air or other gases from the system, which is important for maintaining system integrity and efficiency. In trucks, bleed tubes help ensure systems operate under the correct pressure and without airlocks, which can impede performance 1.

Purpose of Bleed Tube 3252415

This Cummins part is designed to facilitate the removal of air from the fuel system of a truck. Its role is to ensure that the fuel lines are free from air pockets, which can disrupt the fuel delivery to the engine. By maintaining a consistent flow of fuel, the bleed tube contributes to the stable operation of the engine and enhances the overall performance of the truck 2.

Key Features

The Bleed Tube 3252415 is constructed from durable materials, ensuring it can withstand the pressures and conditions within a truck’s fuel system. Its design includes precise fittings and connections that ensure a secure and leak-free integration into the system. Additionally, the bleed tube may feature unique characteristics such as anti-corrosion coatings or reinforced sections to enhance its durability and performance.

Benefits

Incorporating this part into a truck’s fuel system offers several advantages. It contributes to improved system efficiency by ensuring a consistent fuel flow, which is vital for engine performance. The reliability of the bleed tube also plays a role in reducing the likelihood of system failures, thereby enhancing the overall reliability of the truck. Furthermore, by maintaining optimal fuel system conditions, the bleed tube indirectly contributes to the truck’s fuel efficiency and longevity.

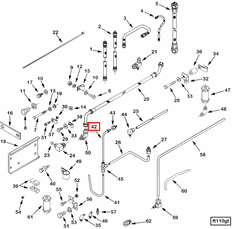

Installation and Integration

Proper installation of the Bleed Tube 3252415 is crucial for its effective operation. It should be integrated into the truck’s fuel system according to the manufacturer’s guidelines, ensuring all connections are secure and the system is free from leaks. Consideration should be given to the orientation and positioning of the bleed tube to facilitate the efficient removal of air from the system. Pre-installation checks, such as verifying the compatibility of the bleed tube with the truck’s fuel system, are recommended to ensure a successful integration.

Troubleshooting and Maintenance

Regular maintenance and inspection of the Bleed Tube 3252415 are recommended to ensure its continued effective operation. Common issues may include blockages or leaks, which can be identified through routine checks and diagnostic procedures. Maintenance practices should include cleaning the bleed tube and its connections, as well as verifying its proper function within the system. Addressing issues promptly can help maintain the efficiency and reliability of the truck’s fuel system.

Cummins Overview

Cummins is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its commitment to producing high-quality components. With a history of innovation and excellence, Cummins has built a reputation for reliability and performance. The company’s dedication to quality is evident in its wide range of products, including the Bleed Tube 3252415, which is designed to meet the demanding requirements of commercial truck applications 3.

Role of Bleed Tube 3252415 in Engine Systems

This part is an integral component in the efficient operation of various engine systems. Its primary function is to manage and regulate the flow of fuel within the engine, ensuring optimal performance and safety.

Integration with Fuel Bypass Mounting

In systems equipped with fuel bypass mounting, the Bleed Tube plays a significant role. It is responsible for redirecting excess fuel that bypasses the main fuel path. This redirection is essential for maintaining consistent fuel pressure and preventing fuel starvation. The Bleed Tube ensures that any surplus fuel is efficiently circulated back into the system, contributing to stable engine operation.

Function in Fuel Tubing Systems

When integrated with fuel tubing, the Bleed Tube facilitates the controlled release of fuel vapors and excess fuel. This is particularly important in high-pressure fuel systems where the buildup of vapors can lead to inefficiencies and potential safety hazards. By allowing a controlled bleed of fuel, the tube helps in maintaining the integrity of the fuel system, ensuring that the fuel delivered to the engine is within the desired parameters for combustion.

In both applications, the Bleed Tube enhances the reliability and efficiency of the fuel system. Its role in managing fuel flow and pressure is fundamental to the overall performance of the engine, making it a key component in the maintenance and operation of modern engine systems.

Conclusion

The Bleed Tube 3252415 by Cummins is a critical component in the fuel system of commercial trucks, designed to ensure efficient and reliable operation. Its role in managing fuel flow and pressure contributes significantly to the overall performance and longevity of the vehicle. Proper installation, regular maintenance, and understanding its function are essential for maximizing the benefits of this Cummins part.

-

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.