This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Compressor Water Inlet Line, identified by part number 3251726, is a component manufactured by Cummins, a leading name in the automotive and heavy-duty truck industry. This part plays a role in the systems of heavy-duty trucks, contributing to the overall efficiency and performance of the vehicle. Cummins is renowned for its commitment to quality and innovation, ensuring that each component, including the Compressor Water Inlet Line, meets rigorous standards 1.

Basic Concepts

The operation of the Compressor Water Inlet Line is grounded in fundamental principles of fluid dynamics and thermal management. This component is integral to the system that regulates the temperature of the compressor by allowing water to enter and circulate. Its role is to facilitate the cooling process, which is vital for maintaining optimal operating conditions within the compressor 2.

Purpose and Function

The primary purpose of the Compressor Water Inlet Line in a truck’s system is to introduce water into the compressor for cooling purposes. This function contributes to the efficiency and performance of the compressor, as it helps to dissipate heat generated during operation. By maintaining a stable temperature, the Compressor Water Inlet Line contributes to the longevity and reliability of the compressor, ensuring that it operates within its designed parameters 3.

Key Features

The 3251726 Compressor Water Inlet Line is characterized by several key features that enhance its functionality and durability. These include a robust material composition designed to withstand the pressures and temperatures of the compressor system, as well as a design that ensures efficient water flow. Additionally, the line may feature unique elements such as reinforced connections or specialized coatings to further improve its performance and resistance to wear.

Benefits

Incorporating the Compressor Water Inlet Line into a truck’s system offers several benefits. It contributes to improved compressor performance by ensuring efficient cooling, which can lead to enhanced overall engine efficiency. The durable construction of the line also means it can withstand the demanding conditions of heavy-duty truck operations, potentially leading to cost savings for fleet operators through reduced maintenance and replacement needs.

Installation and Integration

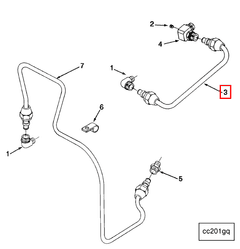

Proper installation and integration of the Compressor Water Inlet Line within a truck’s system are crucial for its effective operation. This process involves ensuring that the line is correctly positioned and securely connected to avoid leaks or inefficiencies. It may also require specific prerequisites or considerations, such as system pressure checks or compatibility assessments with existing components, to ensure seamless integration.

Maintenance and Care

Routine maintenance and care of the Compressor Water Inlet Line are essential for ensuring its optimal performance and longevity. This includes regular inspections for signs of wear or damage, cleaning to remove any deposits that may impede water flow, and checking connections for tightness. Adhering to a maintenance schedule can help prevent issues and ensure the line continues to function effectively.

Troubleshooting

Common issues that may arise with the Compressor Water Inlet Line include leaks, blockages, or reduced efficiency due to wear. Troubleshooting these issues involves a systematic approach to identify the root cause, whether it be a faulty connection, debris within the line, or material degradation. Solutions may range from simple repairs or cleaning to replacement of the line if it is beyond repair.

Cummins Overview

Cummins, the manufacturer of the Compressor Water Inlet Line, has a rich history in the automotive and heavy-duty truck industry. Known for its reputation in quality and innovation, Cummins has consistently delivered components and systems that meet the high demands of commercial and industrial applications. The company’s commitment to excellence is evident in its rigorous testing and quality control processes, ensuring that each product, including the 3251726 Compressor Water Inlet Line, performs reliably under real-world conditions.

Compatibility with Cummins Engines

The Compressor Water Inlet Line, identified by part number 3251726, is designed to ensure efficient water flow to the engine’s compressor, maintaining optimal operating temperatures and enhancing overall performance across various Cummins engines.

ISM CM570 and QSM11 CM570

The ISM CM570 and QSM11 CM570 engines are part of Cummins’ lineup of heavy-duty diesel engines, known for their robust performance and reliability in demanding applications. The Compressor Water Inlet Line for these engines is engineered to fit seamlessly into the cooling system, ensuring that water is directed efficiently to the compressor.

L10 MECHANICAL

The L10 MECHANICAL engine, a staple in various industrial and marine applications, also benefits from the precise fit of the Compressor Water Inlet Line. This part is designed to integrate with the engine’s cooling system, providing a reliable pathway for water to reach the compressor.

M11 CELECT PLUS

The M11 CELECT PLUS engine, known for its advanced technology and performance, requires a high-quality Compressor Water Inlet Line to maintain its cooling system’s efficiency. The part is crafted to fit perfectly within the engine’s design, ensuring that water flows smoothly to the compressor.

Role of Part 3251726 Compressor Water Inlet Line in Engine Systems

The Compressor Water Inlet Line is an essential component in the arrangement of various engine systems, particularly those involving compressor coolant and plumbing. This component facilitates the efficient flow of water into the compressor coolant system, ensuring optimal performance and longevity of the engine.

Integration with Compressor Coolant Systems

In compressor coolant systems, the Compressor Water Inlet Line serves as the primary conduit for water entry. It connects to the plumbing network, allowing water to circulate through the compressor coolant passages. This circulation is vital for dissipating heat generated by the compressor, thereby maintaining operational temperatures within safe limits.

Function within Plumbing Networks

The Compressor Water Inlet Line is integral to the plumbing network of engine systems. It interfaces with various plumbing components to ensure a consistent and regulated water flow. This regulated flow is necessary for the effective cooling of compressor components, which are often subjected to high thermal loads.

Interaction with CRP Coolant

When dealing with CRP (Compressor Recirculation Pump) coolant systems, the Compressor Water Inlet Line plays a significant role. It ensures that the CRP coolant is adequately replenished with fresh water, which is essential for the recirculation process. This interaction helps in maintaining the desired coolant properties and efficiency of the CRP system.

Overall Contribution to Engine Performance

The efficient functioning of the Compressor Water Inlet Line directly impacts the overall performance of engine systems. By ensuring a steady supply of water to the compressor coolant and CRP coolant systems, it aids in thermal management, reduces the risk of overheating, and contributes to the sustained efficiency and reliability of the engine.

Conclusion

The Compressor Water Inlet Line, part number 3251726, is a critical component in the cooling systems of heavy-duty trucks and various Cummins engines. Its role in facilitating efficient water flow to the compressor ensures optimal operating temperatures, contributing to the longevity and reliability of the engine. Proper installation, maintenance, and troubleshooting are essential for maximizing the benefits of this Cummins part, underscoring its importance in engine performance and efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.