This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3202220 Pressure Sensing Tube is a component designed to monitor and regulate pressure within the systems of commercial trucks. Its role is significant in ensuring the efficient and safe operation of these vehicles. This part is integral to maintaining the optimal performance of truck systems by providing accurate pressure readings that inform the operation of various engine and system functions.

Basic Concepts of Pressure Sensing Tubes

A Pressure Sensing Tube is a device used to measure and convey pressure levels within a system. It operates by transmitting pressure from one point to another, typically to a sensor or gauge that interprets the pressure data. This information is crucial for monitoring and regulating the pressure to ensure the system functions within safe and efficient parameters 1.

Purpose of the 3202220 Pressure Sensing Tube

The Cummins 3202220 Pressure Sensing Tube serves a specific function within the operation of a truck. It is designed to monitor pressure levels in the engine or other systems, providing data that is used to adjust and regulate the system’s operation. This ensures that the truck operates efficiently and safely, with the pressure sensing tube playing a key role in this process.

Key Features

The Cummins 3202220 Pressure Sensing Tube is characterized by several design elements that enhance its effectiveness and reliability. These include its durable construction, precise calibration, and compatibility with various truck systems. The tube is designed to withstand the harsh conditions of commercial truck operation, ensuring long-term reliability and performance.

Benefits

The Cummins 3202220 Pressure Sensing Tube offers several advantages. It contributes to improved system performance by providing accurate pressure readings that enable precise system adjustments. This enhances safety by ensuring that the truck operates within safe pressure limits. Additionally, it increases efficiency by optimizing system performance based on real-time pressure data.

Installation and Integration

Proper installation of the Cummins 3202220 Pressure Sensing Tube is crucial for its effective operation. This involves ensuring that the tube is correctly positioned within the truck’s system, with all connections secure and properly sealed. It may also require adjustments to ensure that the tube functions correctly within the system.

Common Issues and Troubleshooting

Typical problems with the Cummins 3202220 Pressure Sensing Tube may include inaccurate readings, leaks, or damage to the tube. Troubleshooting these issues involves checking the tube for physical damage, ensuring all connections are secure, and calibrating the tube to ensure accurate readings. In some cases, replacement of the tube may be necessary.

Maintenance Tips

Regular maintenance of the Cummins 3202220 Pressure Sensing Tube is important to ensure its optimal functioning. This includes periodic inspection for signs of wear or damage, cleaning the tube to remove any debris that may affect its operation, and calibrating the tube to maintain accurate pressure readings.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality products. With a history of innovation and excellence, Cummins has established a strong reputation for producing reliable and efficient components for commercial trucks, including the 3202220 Pressure Sensing Tube.

Pressure Sensing Tube (Part 3202220) in Cummins Engines

The Pressure Sensing Tube, identified by part number 3202220, is a critical component in Cummins engines, including the K19, K38, and K50 series. This part is integral to the engine’s operation, as it plays a pivotal role in the fuel injection system by monitoring and regulating pressure levels.

K19 and K38 Engines

In the K19 and K38 engines, the Pressure Sensing Tube is designed to fit seamlessly into the fuel injection system. It is typically located within the fuel rail, where it interfaces with the fuel injectors. This positioning allows the tube to accurately measure the pressure of the fuel as it is delivered to the injectors. The data collected by the tube is essential for the engine control unit (ECU) to make real-time adjustments to the fuel injection timing and quantity, ensuring optimal engine performance and efficiency.

K50 Engine

For the K50 engine, the Pressure Sensing Tube is similarly integrated into the fuel system. Given the advanced design and technology of the K50, the tube is engineered to withstand higher pressures and temperatures, reflecting the engine’s robust capabilities. The precise placement of the tube ensures that it can effectively communicate with the ECU, providing critical data that helps maintain the engine’s high performance standards.

Common Features Across Engines

Across all these engines, the Pressure Sensing Tube is made from high-quality materials to ensure durability and reliability. It is designed to resist corrosion and wear, which is crucial for maintaining the integrity of the fuel system over time. The tube’s connection points are also engineered to provide a secure and leak-proof seal, preventing any fuel loss and ensuring the engine operates at peak efficiency.

The Pressure Sensing Tube’s role in these engines underscores the importance of precise and reliable components in maintaining engine performance and longevity.

Role of Part 3202220 Pressure Sensing Tube in Engine Systems

The part 3202220 Pressure Sensing Tube is an integral component in the orchestration of various engine systems, ensuring optimal performance and efficiency. It is meticulously designed to interface with several key components, facilitating seamless communication and data transfer within the engine’s control systems.

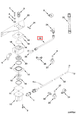

Integration with Injector and Fuel Supply

The Pressure Sensing Tube plays a significant role in the fuel injection system. It is connected to the injector, allowing it to monitor and relay pressure data from the fuel supply. This data is essential for the injector to deliver the precise amount of fuel required, based on the engine’s operating conditions. The tube ensures that the injector receives accurate pressure readings, which are vital for maintaining fuel efficiency and reducing emissions.

Connection to Rail Pressure Switch Mounting

In conjunction with the rail pressure switch mounting, the Pressure Sensing Tube aids in the regulation of fuel rail pressure. It provides continuous feedback to the engine control unit (ECU), allowing for dynamic adjustments to the fuel pressure in the rail. This ensures that the fuel system operates within the desired parameters, enhancing engine performance and reliability.

Interaction with Valve and Timing Control

The Pressure Sensing Tube also interacts with the valve and timing control systems. By providing real-time pressure data, it assists in the precise timing of fuel injection and valve operation. This synchronization is essential for maximizing engine efficiency and power output, while minimizing wear and tear on engine components.

Role in Plumbing and Base Systems

Within the plumbing system, the Pressure Sensing Tube ensures that the fuel lines maintain consistent pressure, preventing issues such as fuel starvation or over-pressurization. At the base of the engine, it contributes to the overall stability and reliability of the fuel system, ensuring that all components work in harmony.

Conclusion

In summary, the part 3202220 Pressure Sensing Tube is a vital link in the chain of engine components, facilitating communication and data transfer that is essential for the precise operation of the fuel injection, rail pressure, valve, and timing control systems. Its role in maintaining the integrity and performance of these systems cannot be overstated.

-

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.