This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

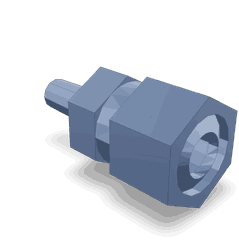

The 3176714 Tube Connector, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the automotive industry, is known for its commitment to innovation and quality. This Cummins part is part of their extensive range of products aimed at enhancing the efficiency and reliability of truck systems.

Basic Concepts of Tube Connectors

Tube connectors are components used in fluid systems to join tubes and facilitate the flow of fluids such as fuel, coolant, or hydraulic fluid. They ensure a secure and leak-proof connection, which is vital for the proper functioning of a truck’s infrastructure. Tube connectors operate by creating a tight seal between the tubes, allowing for the efficient transfer of fluids under various pressures and temperatures 1.

Purpose of the 3176714 Tube Connector

The 3176714 Tube Connector plays a specific role in the operation of a truck by connecting various fluid lines within the truck’s systems. It ensures that fluids are transported efficiently and securely throughout the truck, contributing to the overall performance and reliability of the vehicle 2.

Key Features

The 3176714 Tube Connector is designed with several features that enhance its performance and reliability. It is constructed from high-quality materials that resist corrosion and wear, ensuring durability in demanding environments. The connector features precise threading and sealing mechanisms that provide a secure fit, minimizing the risk of leaks. Additionally, its design allows for easy installation and maintenance, making it a practical choice for commercial truck applications 3.

Benefits

Using the 3176714 Tube Connector offers several advantages. It contributes to improved system efficiency by ensuring a secure and leak-proof connection. Its durable construction enhances the longevity of the fluid systems, reducing the need for frequent replacements. Additionally, the connector’s design facilitates ease of installation, saving time and labor during maintenance procedures.

Installation Process

Proper installation of the 3176714 Tube Connector involves several steps to ensure a secure and efficient connection. Begin by cleaning the tube ends to remove any debris or contaminants. Apply the appropriate sealant to the threads of the connector, if required. Carefully screw the connector onto the tube, ensuring a tight fit without over-tightening, which could damage the threads. Finally, inspect the connection for any signs of leaks or irregularities.

Maintenance Tips

To ensure the longevity and optimal performance of the 3176714 Tube Connector, regular maintenance is recommended. Inspect the connector periodically for signs of wear, corrosion, or leaks. Clean the connector and surrounding areas to remove any buildup that could affect its performance. If any issues are detected, address them promptly to prevent further damage to the fluid systems.

Troubleshooting Common Issues

Common issues associated with tube connectors include leaks and connection failures. To address these problems, first, ensure that the connector is properly installed and tightened. If leaks persist, check for damage to the connector or tube ends and replace any compromised parts. Regularly inspecting and maintaining the connector can help prevent these issues from occurring.

Compatibility and Applications

The 3176714 Tube Connector is designed for use in various truck models and fluid systems. It is compatible with specific fluid types and pressure ratings, making it suitable for a range of commercial truck applications. When selecting a tube connector, it is important to consider the specific requirements of the truck’s fluid systems to ensure proper fit and function.

Safety Considerations

When working with the 3176714 Tube Connector, it is important to observe safety protocols and precautions. Handle fluids carefully to avoid spills and contamination. Ensure that all connections are secure to prevent leaks, which could pose a safety hazard. Follow manufacturer guidelines for installation and maintenance to ensure the safe and efficient operation of the truck’s fluid systems.

Environmental Impact

The use and disposal of the 3176714 Tube Connector should be considered in terms of environmental impact. Proper disposal of the connector and any associated fluids is important to minimize environmental harm. Recycling options may be available for certain materials, and it is advisable to follow local regulations and guidelines for disposal.

About Cummins

Cummins is a leading manufacturer in the automotive industry, known for its innovative products and commitment to quality. With a history of providing reliable and efficient solutions for commercial vehicles, Cummins continues to be a trusted name in the industry. Their product range includes a variety of components designed to enhance the performance and reliability of trucks and other heavy-duty vehicles.

Tube Connector 3176714 in Cummins Engines

The Tube Connector part number 3176714, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the engine’s cooling system, ensuring efficient heat transfer and maintaining optimal engine temperature.

K19 and K38 Engines

In the K19 and K38 engines, the Tube Connector 3176714 plays a pivotal role in the coolant flow system. It connects the coolant passages within the engine block, facilitating the circulation of coolant. This ensures that the engine operates within its optimal temperature range, preventing overheating and maintaining efficiency.

N14 MECHANICAL Engine

For the N14 MECHANICAL engine, the Tube Connector 3176714 is equally essential. It is designed to withstand the high pressures and temperatures typical of this engine model. The connector ensures that the coolant flows smoothly through the engine, which is crucial for maintaining the engine’s performance and longevity. Its robust construction and precise fit are critical for the engine’s reliability and efficiency.

Role of Part 3176714 Tube Connector in Engine Systems

The 3176714 Tube Connector is an integral component in the fuel system of engine assemblies, facilitating the secure and efficient transfer of fuel throughout various engine components.

In the context of base parts, the Tube Connector ensures that the fuel tubing is properly aligned and sealed, preventing leaks and maintaining the integrity of the fuel supply.

For the Electronically Controlled Braking Module (EBM), the Tube Connector plays a significant role in the EBM tubing by providing a reliable connection point. This is essential for the precise control of braking systems, where fuel delivery must be consistent and unimpeded.

Within the broader fuel system, the Tube Connector is employed in both the fuel left bank manifold and the fuel right bank manifold. It ensures that fuel is evenly distributed to each bank, which is vital for balanced engine performance.

The fuel manifold relies on the Tube Connector to join various fuel lines, allowing for the regulated flow of fuel to different parts of the engine. This component is also used in the fuel plumbing to create a cohesive network of fuel lines that transport fuel from the fuel supply mounting to the engine.

Additionally, the Tube Connector is utilized in conjunction with the fuel pressure transducer. This setup allows for accurate measurement of fuel pressure, ensuring that the engine receives the correct amount of fuel under varying conditions.

In summary, the 3176714 Tube Connector is a fundamental element in the fuel system, enhancing the reliability and efficiency of fuel delivery across multiple engine components.

Conclusion

The 3176714 Tube Connector is a vital component in the fluid systems of commercial trucks, ensuring efficient and secure fluid transfer. Its durable construction, precise design, and ease of installation make it a reliable choice for maintaining the performance and reliability of truck systems. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons, 2019.

↩ -

Sully, F. K. Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing, 1998.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.