This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3065108 Breather Tube is a component designed to facilitate the operation of commercial trucks. Its role is to ensure the engine system functions efficiently by managing pressure and moisture within the engine crankcase. Understanding its purpose and significance is fundamental for maintaining optimal truck performance.

Basic Concepts of Breather Tubes

A breather tube is an integral part of a truck’s engine system, designed to allow air to enter and exit the engine crankcase. This process helps in maintaining a balanced pressure within the crankcase, which is vital for the proper operation of the engine 1. By allowing air to circulate, the breather tube also aids in removing moisture and contaminants that could otherwise accumulate and affect engine performance.

Purpose of the 3065108 Breather Tube

The 3065108 Breather Tube is specifically engineered to play a role in the pressure equalization and moisture removal from the engine crankcase. It ensures that the internal pressure of the crankcase remains consistent with the atmospheric pressure, which is important for the efficient operation of the engine. Additionally, by facilitating the removal of moisture, it helps in preventing the formation of sludge and other deposits that could impair engine performance 2.

Key Features

This Cummins part is constructed from durable materials that are resistant to the harsh conditions within an engine environment. Its design includes features that enhance its performance and longevity, such as a robust construction that can withstand high temperatures and pressures. Additionally, the tube is designed to be compatible with a wide range of truck models, ensuring versatility and ease of use.

Benefits of Using the 3065108 Breather Tube

Utilizing the 3065108 Breather Tube can lead to improved engine efficiency, as it helps maintain optimal pressure and moisture levels within the crankcase. This can result in reduced maintenance needs, as the engine is less likely to suffer from issues related to pressure imbalances or moisture accumulation. Furthermore, the enhanced performance and durability of the breather tube contribute to the overall longevity of engine components.

Installation and Compatibility

Proper installation of the 3065108 Breather Tube is important for ensuring its effective operation. Guidelines for installation should be followed to ensure that the tube is securely fitted and functions as intended. Compatibility with specific truck models and engine types should be considered to ensure optimal performance and integration within the engine system.

Troubleshooting and Maintenance

Common issues associated with breather tubes include blockages or leaks, which can affect engine performance. Diagnosing these problems involves checking for signs of moisture or pressure imbalances within the crankcase. Regular maintenance, such as cleaning or replacing the breather tube as needed, can help ensure its longevity and efficiency.

Regulatory and Safety Considerations

The use of breather tubes in commercial trucks is subject to regulatory standards and safety considerations. Compliance with emissions standards and safety regulations is important to ensure that the truck operates within legal and environmental guidelines. Breather tubes, including the 3065108, are designed to meet these standards, contributing to the overall safety and environmental performance of the vehicle.

Environmental Impact

Efficient breather tubes like the 3065108 contribute to reduced emissions and improved fuel efficiency. By maintaining optimal engine performance, they help in minimizing the environmental impact of commercial trucks. This is achieved through the efficient management of pressure and moisture within the engine, which can lead to smoother operation and reduced fuel consumption 3.

Cummins: A Brief Overview

Cummins Inc. is a leader in the automotive industry, known for its commitment to innovation and quality. With a history of developing reliable and efficient engine components, Cummins offers a wide range of products designed to meet the needs of commercial truck operators. The company’s dedication to excellence is reflected in its product offerings, including the 3065108 Breather Tube, which is engineered to enhance engine performance and durability.

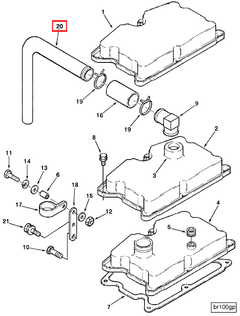

Breather Tube (Part 3065108) in Cummins Engines

The Breather Tube, identified by part number 3065108, is a critical component in the Cummins N14 CELECT, N14 CELECT PLUS, and N14 MECHANICAL engines. This part is integral to the engine’s ventilation system, ensuring that the crankcase is properly ventilated to prevent the buildup of harmful gases and maintain optimal engine performance.

N14 CELECT and N14 CELECT PLUS Engines

In the N14 CELECT and N14 CELECT PLUS engines, the Breather Tube is designed to connect the crankcase ventilation system to the intake manifold. This configuration allows for the expulsion of gases from the crankcase into the intake manifold, where they are subsequently drawn into the combustion process. This not only helps in reducing the environmental impact by minimizing emissions but also aids in maintaining the engine’s efficiency and longevity.

N14 MECHANICAL Engine

For the N14 MECHANICAL engine, the Breather Tube serves a similar function, ensuring that the crankcase ventilation system is effectively linked to the intake manifold. The design and placement of the Breather Tube in this engine variant are tailored to meet the specific requirements of the mechanical control system, ensuring that the engine operates smoothly and efficiently.

Common Functionality

Across all these engine variants, the Breather Tube is a key component in the crankcase ventilation system. It is typically made from durable materials to withstand the high temperatures and pressures within the engine. The tube’s design ensures that it can efficiently transfer gases from the crankcase to the intake manifold without causing leaks or blockages.

By integrating the Breather Tube into the engine’s design, Cummins ensures that the engines maintain optimal performance and reliability, while also adhering to environmental standards. This part is a testament to Cummins’ commitment to quality and innovation in engine design.

Role of Part 3065108 Breather Tube in Engine Systems

The 3065108 Breather Tube is an essential component in maintaining the health and efficiency of engine systems. It is specifically designed to work in conjunction with the crankcase breather system, which is responsible for releasing pressure that builds up inside the crankcase as the engine operates.

Integration with Crankcase Breather System

The Breather Tube connects to the crankcase breather, allowing the release of gases and vapors that accumulate during engine operation. This connection ensures that the crankcase does not become pressurized, which could lead to oil leaks, reduced engine performance, and potential damage to seals and gaskets.

Function in Mounting Systems

In mounting systems, the Breather Tube plays a significant role by providing a pathway for these gases to escape without contaminating the engine’s surrounding components. Proper mounting of the Breather Tube ensures that it remains secure and effectively channels gases away from sensitive engine parts, maintaining a clean and efficient operating environment.

Overall System Contribution

By facilitating the smooth operation of the crankcase breather and ensuring secure mounting, the Breather Tube contributes to the overall reliability and performance of the engine. It helps in maintaining optimal pressure levels within the crankcase, thereby supporting the engine’s longevity and efficiency.

Conclusion

The 3065108 Breather Tube by Cummins is a vital component for the efficient operation of commercial truck engines. Its role in managing pressure and moisture within the engine crankcase ensures optimal engine performance and longevity. Proper installation, regular maintenance, and understanding its function within the engine system are key to maximizing the benefits of this part.

-

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Taghavifar, Hamid, and Aref Mardani. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ -

Hillier, Alma. Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.