This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3060059 Breather Tube is a component designed for use in commercial trucks, specifically within Cummins engine systems. Its purpose is to facilitate the release of pressure and contaminants from the engine’s crankcase, contributing to the overall efficiency and longevity of the engine. Understanding its function and significance is vital for maintaining optimal engine performance in heavy-duty applications.

Basic Concepts of Breather Tubes

Breather tubes are integral to engine systems, serving as a pathway for the release of gases and contaminants that accumulate within the crankcase. By allowing these substances to escape, breather tubes help maintain a stable pressure environment within the engine, which is crucial for efficient operation. Additionally, they play a role in preventing the buildup of moisture and sludge, which can adversely affect engine components and performance 1.

Purpose of the Cummins 3060059 Breather Tube

The Cummins 3060059 Breather Tube is specifically engineered to enhance the operation of Cummins engines in commercial trucks. It allows for the controlled release of pressure and contaminants from the crankcase, which helps in maintaining engine efficiency and reducing wear on internal components. By ensuring that the crankcase remains free of excess pressure and contaminants, this breather tube contributes to the engine’s overall performance and longevity 2.

Key Features

The Cummins 3060059 Breather Tube is characterized by its durable material composition and design elements that enhance its functionality. It is constructed from high-quality materials to withstand the harsh conditions of commercial truck operations. Its design includes features that facilitate efficient pressure release and contaminant removal, ensuring that the engine operates under optimal conditions 3.

Benefits

The use of the Cummins 3060059 Breather Tube offers several advantages. It contributes to improved engine efficiency by maintaining a stable crankcase pressure. Additionally, it reduces the need for frequent maintenance by preventing the buildup of contaminants that can lead to engine wear. The breather tube’s durable construction also enhances the engine’s longevity, making it a valuable component for commercial truck operators 4.

Installation Process

Installing the Cummins 3060059 Breather Tube requires careful attention to ensure proper function. The process involves securing the tube to the engine’s crankcase and ensuring a tight seal to prevent leaks. Tools and additional components may be required, depending on the specific engine model and installation environment. Following the manufacturer’s guidelines is recommended to ensure a successful installation.

Troubleshooting Common Issues

Common issues associated with breather tubes include blockages, leaks, and contamination. These problems can arise from debris accumulation, wear and tear, or improper installation. Addressing these issues may involve cleaning the breather tube, repairing or replacing damaged components, and ensuring proper installation practices are followed. Regular maintenance and inspections can help identify and resolve these issues before they lead to significant engine problems.

Maintenance Tips

To ensure the optimal performance of the Cummins 3060059 Breather Tube, regular maintenance is recommended. This includes inspecting the tube for signs of wear or damage, cleaning it to remove any accumulated contaminants, and ensuring that it remains securely attached to the engine. Replacement should be considered if the breather tube shows significant signs of wear or if it fails to function properly, ensuring continued engine efficiency and longevity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. Its product range includes a variety of engines and components designed to meet the demanding requirements of heavy-duty applications, ensuring optimal performance and durability for commercial truck operators.

Breather Tube (Part 3060059) in Cummins Engines

The Breather Tube, identified by part number 3060059, is a critical component in the Cummins N14 CELECT, N14 CELECT PLUS, and N14 MECHANICAL engines. This part plays a vital role in maintaining the engine’s operational integrity by facilitating the release of gases and preventing the buildup of pressure within the engine’s crankcase.

N14 CELECT and N14 CELECT PLUS Engines

In the N14 CELECT and N14 CELECT PLUS engines, the Breather Tube (3060059) is designed to connect the crankcase ventilation system to the outside atmosphere. This connection ensures that any gases produced during the combustion process are safely expelled, preventing pressure build-up that could lead to engine damage. The breather tube also helps in maintaining a clean and efficient crankcase environment by allowing the escape of volatile organic compounds (VOCs) and other byproducts of combustion.

N14 MECHANICAL Engine

For the N14 MECHANICAL engine, the Breather Tube (3060059) serves a similar function. It is integral to the crankcase ventilation system, ensuring that gases are vented out of the engine. This is particularly important in the N14 MECHANICAL engine, where the absence of electronic controls necessitates robust mechanical systems to maintain engine health. The breather tube in this engine ensures that the crankcase remains free from excessive pressure, which could otherwise compromise the engine’s performance and longevity.

Common Functionality

Across all three engine variants, the Breather Tube (3060059) is a key component in the crankcase ventilation system. Its role is to provide a pathway for gases to escape from the crankcase, thereby preventing pressure build-up and maintaining a clean and efficient engine environment. This is crucial for the overall health and performance of the engine, ensuring that it operates smoothly and reliably over time.

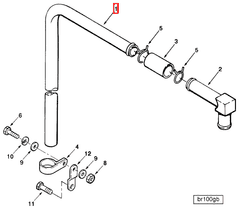

Role of Part 3060059 Breather Tube in Engine Systems

The Part 3060059 Breather Tube is an essential component in managing the ventilation of engine systems. It is specifically designed to interface with the crankcase breather system, ensuring that any gases or vapors produced within the crankcase are effectively vented.

When integrated with the crankcase, the breather tube allows for the release of pressure that builds up due to the combustion process. This is vital for maintaining the integrity of the crankcase and preventing oil contamination from unburned fuel and combustion byproducts.

The breather mounting tube, which is a part of the breather system, connects the breather tube to the engine’s structure. This connection ensures a secure fit and proper alignment, facilitating the smooth flow of gases from the crankcase to the atmosphere or to a filtration system where they can be processed before release.

In summary, the Part 3060059 Breather Tube works in conjunction with the crankcase and breather mounting tube to maintain a balanced pressure environment within the engine, contributing to the overall efficiency and longevity of the engine system.

Conclusion

The Cummins 3060059 Breather Tube is a critical component for maintaining the efficiency and longevity of Cummins engines in commercial trucks. By facilitating the release of pressure and contaminants from the crankcase, it ensures a stable operating environment and reduces the risk of engine wear. Regular maintenance and proper installation are essential for maximizing the benefits of this component.

-

Sean Bennett, Modern Diesel Technology: Light Duty Diesels, Cengage Learning, 2012.

↩ -

Haoran Hu, Simon J Baseley and Xubin Song, Advanced Hybrid Powertrains for Commercial Vehicles Second Edition, SAE International, 2021.

↩ -

Jon M. Quigley, SAE International’s Dictionary of Testing, Verification and Validation, SAE International, 2023.

↩ -

Hans B. Pacejka, Tyre and Vehicle Dynamics, Butterworth-Heinemann, 2006.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.