This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

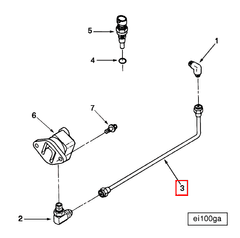

The Cummins 3058716 Pressure Sensing Tube is a component designed to monitor and relay pressure data within the systems of commercial trucks. Its purpose is to ensure accurate pressure readings are transmitted to the truck’s control systems, contributing to the efficient and reliable operation of the vehicle. This component is integral to maintaining the performance and safety standards of commercial trucks.

Basic Concepts of Pressure Sensing Tubes

A pressure sensing tube is a conduit that facilitates the transfer of pressure from a specific point in a system to a pressure sensor or gauge. Within a truck’s system, these tubes play a role in monitoring various pressures, such as fuel, oil, or air pressure, which are vital for the truck’s operation. The principles of pressure sensing technology involve the transmission of pressure through a fluid or gas medium, which is then converted into an electrical signal by the sensor for processing by the truck’s electronic control unit 1.

Role of the 3058716 Pressure Sensing Tube in Truck Operation

The Cummins 3058716 Pressure Sensing Tube is specifically designed to integrate with the truck’s pressure monitoring systems. It plays a role in the accurate transmission of pressure data from the source to the sensor, ensuring that the truck’s control systems receive precise information. This integration is crucial for the truck’s engine management system to make informed decisions regarding fuel injection, turbocharging, and other critical functions.

Key Features of the 3058716 Pressure Sensing Tube

The Cummins 3058716 Pressure Sensing Tube is characterized by several key features. It is constructed from durable materials that can withstand the harsh conditions within a truck’s engine compartment. The design elements of the tube, such as its length, diameter, and connection types, are tailored to fit seamlessly within the truck’s system. Additionally, technological advancements in the tube’s manufacturing process contribute to its reliability and performance.

Benefits of Using the 3058716 Pressure Sensing Tube

Utilizing the Cummins 3058716 Pressure Sensing Tube offers several advantages. It contributes to improved performance by ensuring accurate pressure readings, which are essential for the optimal operation of the truck’s systems. The tube’s reliability reduces the likelihood of system failures, and its efficient design helps maintain the overall efficiency of the truck’s operations.

Installation and Integration

Proper installation and integration of the Cummins 3058716 Pressure Sensing Tube within a truck’s system require adherence to specific guidelines. It is important to ensure that the tube is correctly routed and secured to prevent any kinks or obstructions that could affect pressure readings. Integration with the truck’s existing systems should be performed according to the manufacturer’s instructions to ensure compatibility and optimal performance.

Maintenance and Troubleshooting

Regular maintenance practices for the Cummins 3058716 Pressure Sensing Tube include inspecting the tube for any signs of wear, damage, or leaks. It is also important to ensure that the connections are secure and that there are no obstructions in the tube. Troubleshooting may involve checking for accurate pressure readings and verifying the tube’s integration with the truck’s systems.

Common Issues and Solutions

Common problems associated with the Cummins 3058716 Pressure Sensing Tube may include inaccurate pressure readings, leaks, or damage to the tube. Solutions or corrective actions can range from recalibrating the sensor to replacing the tube if it is damaged. Regular inspections and maintenance can help prevent many of these issues.

Compatibility and Applications

The Cummins 3058716 Pressure Sensing Tube is designed to be compatible with a range of truck models and is applicable in various operational scenarios. Its versatility makes it a valuable component for maintaining the performance and reliability of commercial trucks across different applications.

Cummins Corporation Overview

Cummins Corporation is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the automotive industry. The company’s product range includes a variety of components and systems designed to enhance the performance and efficiency of vehicles.

Pressure Sensing Tube (Part 3058716) in Cummins Engines

The Pressure Sensing Tube (Part 3058716) is a critical component in various Cummins engines, including the N14 CELECT. This part plays a pivotal role in ensuring the engine’s performance and efficiency by accurately measuring the pressure within the engine’s system.

In the N14 CELECT engine, the Pressure Sensing Tube is integral to the engine’s operation, providing essential data to the engine control unit (ECU). This data is crucial for maintaining optimal fuel injection timing and air-fuel ratio, which directly impacts the engine’s power output and fuel efficiency.

The Pressure Sensing Tube is designed to withstand the harsh conditions within the engine, including high temperatures and pressures. Its robust construction ensures longevity and reliability, making it a dependable part for the N14 CELECT engine.

For engines within the same group or similar configurations, the Pressure Sensing Tube (Part 3058716) serves the same fundamental purpose. It is engineered to fit seamlessly into the engine’s design, ensuring compatibility and performance across various models.

This part’s precision and accuracy are vital for the engine’s overall health and performance, making it a key component in the maintenance and operation of Cummins engines.

Role of Part 3058716 Pressure Sensing Tube in Engine Systems

The Part 3058716 Pressure Sensing Tube is an integral component in the orchestration of various engine systems, ensuring precise and reliable data transmission for optimal engine performance.

Integration with Base Parts and Engine Instruments

When integrated with base parts, the Pressure Sensing Tube facilitates the connection between the engine and its instruments. This seamless integration allows for accurate pressure readings, which are essential for the proper functioning of engine instruments. The tube acts as a conduit, transferring pressure data from the engine to the instruments, enabling real-time monitoring and adjustments.

Interaction with Instrument and Engine

The Pressure Sensing Tube plays a significant role in the interaction between the instrument and the engine. By providing a direct pathway for pressure data, it ensures that the instrument receives up-to-date information about the engine’s operating conditions. This data is vital for the instrument to make informed decisions and adjustments, contributing to the engine’s efficiency and reliability.

Collaboration with Oil Sensor and Sensor Plumbing

In conjunction with the oil sensor, the Pressure Sensing Tube ensures that oil pressure within the engine is accurately monitored. This is particularly important for maintaining the engine’s lubrication system, preventing wear and tear, and ensuring longevity. The tube’s compatibility with sensor plumbing allows for a streamlined installation process, minimizing the risk of leaks and ensuring a secure connection.

Overall Contribution to Engine Systems

Overall, the Part 3058716 Pressure Sensing Tube is a fundamental component in the engine’s sensor network. Its role in transmitting pressure data ensures that all connected systems—from the base parts to the engine instruments, and from the oil sensor to the sensor plumbing—operate harmoniously. This contributes to the engine’s overall performance, reliability, and longevity.

Conclusion

The Cummins 3058716 Pressure Sensing Tube is a vital component in the operation and maintenance of commercial trucks and Cummins engines. Its role in accurately transmitting pressure data ensures the optimal performance and reliability of the vehicle’s systems. Proper installation, maintenance, and understanding of its integration within the engine systems are crucial for maximizing the benefits of this Cummins part.

-

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.