This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

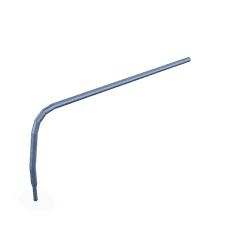

The Cummins 3058412 Breather Tube is a specialized component designed for commercial trucks, integral to the engine system’s efficiency and reliability. Understanding its function and operation is essential for maintaining the engine’s health and performance.

Basic Concepts of Breather Tubes

Breather tubes are vital for an engine’s ventilation system, allowing air to enter and exit the engine crankcase to maintain balanced pressure 1. This balance is crucial for preventing excessive pressure buildup, which could lead to leaks or damage. Additionally, breather tubes help expel contaminants, protecting the engine’s internal components.

Purpose of the Cummins 3058412 Breather Tube

The Cummins 3058412 is engineered to facilitate air exchange within the engine system of commercial trucks. It maintains pressure equilibrium within the crankcase, essential for smooth engine operation, and aids in preventing contamination by releasing air and moisture accumulated during engine operation.

Key Features

The Cummins 3058412 is constructed with materials and design elements that enhance durability and performance. Its material composition ensures resistance to harsh engine conditions, and its design optimizes airflow and efficiency, contributing to the engine’s ventilation system effectiveness.

Benefits of Using the Cummins 3058412 Breather Tube

Incorporating the Cummins 3058412 into a truck’s engine system offers advantages such as improved engine performance through optimal crankcase pressure levels and enhanced engine longevity and reliability by preventing contamination and reducing component wear.

Installation Considerations

Proper installation of the Cummins 3058412 is crucial for its effective operation. Following guidelines and best practices ensures the tube is correctly positioned and securely attached within the engine system, contributing to the truck’s overall efficiency.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 3058412 is important for its continued effective operation. Regular inspections for wear or damage and troubleshooting steps for common issues like blockages or leaks are essential.

Cummins Corporation Overview

Cummins Inc. is renowned in the commercial truck industry for its engine and component products. The company’s history of innovation and quality is reflected in its offerings, including the Cummins 3058412, making its components a popular choice among commercial truck operators and maintenance professionals.

Compatibility with Engine Models

The Cummins 3058412 Breather Tube is compatible with several engine models, including the N14 CELECT, N14 CELECT PLUS, and N14 MECHANICAL engines. It is also engineered to integrate smoothly with NH/NT 855 engines, facilitating necessary air exchange to prevent contaminants from entering the engine’s crankcase.

Role of the Cummins 3058412 in Engine Systems

The Cummins 3058412 plays a significant role in maintaining engine efficiency and reliability. It works in conjunction with the crankcase and the Engine Breather Module (EBM) to manage the ventilation of gases within the engine.

Integration with Crankcase

The crankcase, housing the crankshaft and connecting rods, produces gases and vapors during engine operation. The Breather Tube facilitates the release of these gases, preventing a buildup that could lead to increased pressure and ensuring the structural integrity of the crankcase.

Function within the Engine Breather Module (EBM)

The EBM filters and regulates gases expelled from the crankcase. The Breather Tube connects directly to the EBM, allowing for a controlled flow of gases and ensuring contaminants or moisture within the expelled gases are effectively managed.

Mounting and Breather Tube Assembly

Proper mounting of the Breather Tube is essential for its effective function. It must be securely attached to both the crankcase and the EBM to ensure a sealed connection, preventing leaks that could introduce contaminants or allow lubrication to escape.

Conclusion

The Cummins 3058412 Breather Tube is a critical component in the ventilation and maintenance of engine systems. Its proper installation and function are key to ensuring the engine operates efficiently and remains protected against internal pressure and contamination.

-

John F Kershaw, SAE International’s Dictionary for Automotive Engineers, SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.