This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Corrosion Resistor Tube 3049281 by Cummins is a specialized component designed to enhance the durability and reliability of heavy-duty truck systems. Its primary function is to protect critical components from the detrimental effects of corrosion, thereby ensuring the longevity and efficient operation of the truck.

Basic Concepts of Corrosion Resistor Tubes

Corrosion resistor tubes are engineered to safeguard various truck components from corrosion, a natural process that can significantly degrade metal parts over time 1. These tubes function by creating a barrier between the metal components and corrosive elements, such as moisture, chemicals, and salts. Their importance lies in maintaining the structural integrity and performance of truck systems, preventing costly repairs and downtime.

Purpose and Role in Truck Operation

The 3049281 Corrosion Resistor Tube plays a specific role in the operation of a truck by protecting critical components from corrosion. It is typically placed in areas where metal parts are most vulnerable to environmental factors. This tube interacts with other components by providing a protective layer that shields them from corrosive agents, ensuring that the truck operates efficiently and reliably over its lifespan.

Key Features

The 3049281 Corrosion Resistor Tube boasts several key features that enhance its performance. It is composed of high-quality materials resistant to corrosion, ensuring durability in harsh environments 2. The design elements include a robust construction that can withstand significant stress and pressure. Additionally, it may feature unique characteristics such as a specialized coating or treatment that further enhances its protective capabilities.

Benefits

The benefits of the 3049281 Corrosion Resistor Tube include improved durability of truck components, enhanced protection against environmental factors, and potential cost savings over time 3. By preventing corrosion, this tube helps maintain the structural integrity of the truck, reducing the need for frequent repairs and replacements. This results in lower maintenance costs and increased operational efficiency.

Installation Considerations

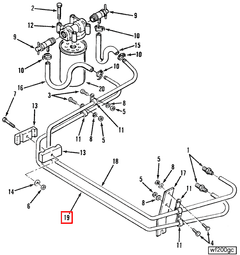

Proper installation of the 3049281 Corrosion Resistor Tube is crucial for its effective performance. Guidelines for installation include ensuring that the tube is correctly positioned to cover vulnerable areas and that it is securely fastened. Any prerequisites, such as cleaning the surface before installation, should be followed. Special tools may be required to ensure a precise fit and optimal protection.

Maintenance and Troubleshooting

Maintaining the 3049281 Corrosion Resistor Tube involves regular inspections to ensure it remains intact and effective. Common issues may include damage to the tube or degradation of its protective coating. Troubleshooting steps include repairing or replacing the tube if necessary and reapplying any protective coatings to maintain its effectiveness. Regular maintenance helps ensure the tube continues to provide optimal protection against corrosion.

Environmental and Operational Factors

Various environmental and operational factors can impact the performance of the 3049281 Corrosion Resistor Tube. These include exposure to harsh chemicals, extreme temperatures, and high humidity. Recommendations for mitigating these effects include regular inspections and maintenance, ensuring the tube remains in good condition, and applying additional protective measures if necessary to enhance its durability in challenging environments.

Cummins Overview

Cummins is a renowned manufacturer in the automotive industry, known for its high-quality engines and components. With a rich history of innovation and excellence, Cummins offers a wide range of products designed to enhance the performance and reliability of vehicles. The company’s reputation for producing durable and efficient parts makes it a trusted choice for heavy-duty truck applications 4.

Integration of Part 3049281 Corrosion Resistor Tube in Engine Systems

The 3049281 Corrosion Resistor Tube is designed to enhance the durability and efficiency of engine systems by providing a robust solution to corrosion challenges. This component is strategically integrated into various engine subsystems to ensure optimal performance and longevity.

Fuel System Integration

In the fuel system, the Corrosion Resistor Tube is employed in the fuel lines and injectors. Its resistance to corrosion ensures that fuel delivery remains consistent, preventing blockages and maintaining fuel efficiency. The tube’s material properties allow it to withstand the corrosive effects of ethanol-blended fuels, which are increasingly common in modern engines.

Cooling System Application

Within the cooling system, the Corrosion Resistor Tube is used in radiator hoses and coolant passages. It effectively resists the corrosive nature of coolant additives, ensuring that the cooling system operates efficiently without degradation over time. This integration helps maintain optimal engine temperature, preventing overheating and extending the life of the cooling components.

Exhaust System Usage

In the exhaust system, the Corrosion Resistor Tube is utilized in the exhaust manifolds and catalytic converter housings. Its corrosion-resistant properties are vital in withstanding the high temperatures and acidic byproducts of combustion. This ensures that the exhaust system components remain intact, contributing to reduced emissions and improved engine performance.

Lubrication System Role

The Corrosion Resistor Tube also finds its place in the lubrication system, particularly in oil galleries and passages. Its ability to resist corrosion from acidic byproducts in the oil helps maintain the integrity of the lubrication system, ensuring that engine components receive consistent and clean oil flow. This integration is essential for reducing wear and tear on moving parts.

Electrical System Integration

In the electrical system, the Corrosion Resistor Tube is used in wiring harnesses and connectors that are exposed to moisture and corrosive environments. Its protective properties help prevent electrical failures due to corrosion, ensuring reliable performance of engine control units and sensors.

Conclusion

By integrating the 3049281 Corrosion Resistor Tube into these engine subsystems, engineers and mechanics can significantly enhance the reliability and performance of engine systems, ultimately leading to improved vehicle longevity and efficiency.

-

John F Kershaw, SAE International’s Dictionary for Automotive Engineers, SAE International, 2023.

↩ -

John Dixon, Modern Diesel Technology Preventive Maintenance and Inspection, Delmar Cengage Learning, 2010.

↩ -

Tim Giles, Automotive Engines Diagnosis Repair and Rebuilding, Cengage Learning, 2019.

↩ -

David Crolla, Crolla Encyclopedia, Wiley, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.