2882562

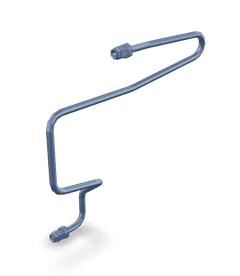

Pressure Sensing Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction to Pressure Sensing Tubes

Pressure sensing tubes are critical in modern engines, particularly those used in commercial trucks. These components measure the pressure within various engine parts, ensuring optimal performance and efficiency. This article delves into the Cummins Pressure Sensing Tube Part #2882562, exploring its function, significance, and maintenance. 1

Basic Concepts of Pressure Sensing Tubes

A Pressure Sensing Tube is a device designed to measure the pressure of fluids or gases within an engine. It typically comprises a flexible tube connected to a pressure sensor. This setup allows the sensor to obtain accurate pressure readings without direct exposure to the engine’s harsh environment, ensuring precise measurements and protecting the sensor from damage. 2

How a Pressure Sensing Tube Works

The Pressure Sensing Tube operates by transmitting pressure from the engine’s internal components to the sensor. The sensor then converts this pressure into an electrical signal, which is sent to the engine control unit (ECU). The ECU uses this data to adjust engine parameters such as fuel injection timing, ignition timing, and other critical functions to maintain optimal performance. 3

Purpose of the Cummins Pressure Sensing Tube Part #2882562

The Cummins Pressure Sensing Tube Part #2882562 is specifically engineered to monitor the pressure within the engine’s turbocharger system. Accurate pressure readings are essential for maintaining the efficiency of the turbocharger, which directly impacts the engine’s power output, fuel economy, and overall performance.

Importance in Truck Operations

For fleet operators and mechanics, understanding the function of the Pressure Sensing Tube is crucial. Proper functioning of this component ensures that the turbocharger operates within its designed parameters, preventing potential damage and maintaining the engine’s efficiency. This is particularly vital for commercial trucks, where reliability and performance are paramount.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting of the Pressure Sensing Tube can prevent potential issues before they become critical. Here are some steps to ensure the tube is functioning correctly:

-

Visual Inspection: Check the tube for any signs of wear, cracks, or leaks. A damaged tube can lead to inaccurate pressure readings.

-

Connection Check: Ensure that the tube is securely connected to both the pressure sensor and the turbocharger. Loose connections can cause leaks and affect performance.

-

Sensor Calibration: Periodically calibrate the pressure sensor to ensure it is providing accurate readings. This can be done using specialized diagnostic tools.

-

Fluid Levels: Check the fluid levels in the turbocharger system to ensure there are no contaminants that could damage the tube or sensor.

Cummins: A Leader in Engine Technology

Cummins is a renowned manufacturer of engines and related components, known for its innovation and reliability. The company has a long history of producing high-quality parts that meet the demanding needs of commercial truck operators. The Pressure Sensing Tube Part #2882562 is a testament to Cummins’ commitment to providing durable and efficient components.

Compatibility with Cummins Engines

The Pressure Sensing Tube, part number 2882562, is compatible with various Cummins engine models, including:

- ISX12 Series Engines: ISX12 CM2350 X102, ISX12 G CM2180 EJ, ISX12/ISX11.9 CM2250

- QSX11.9 Series Engine: QSX11.9 CM2250 ECF

These engines benefit from the precise pressure readings provided by the tube, which helps in maintaining the engine’s performance and longevity.

Installation and Functionality

While the specific installation process may vary slightly between engine models, the Pressure Sensing Tube is generally designed to be easily integrated into the engine’s existing systems. It is crucial to follow the manufacturer’s guidelines for proper installation to ensure that the engine continues to operate at peak performance.

Role of Part 2882562 Pressure Sensing Tube in Engine Systems

The part 2882562 Pressure Sensing Tube is an integral component in the monitoring and regulation of various engine systems. Its primary function is to accurately measure and transmit pressure data from specific points within the engine to the engine control unit (ECU). This data is essential for the ECU to make informed decisions regarding fuel injection, ignition timing, and other critical parameters.

Integration with Recirculation Systems

In recirculation systems, such as Exhaust Gas Recirculation (EGR), the Pressure Sensing Tube plays a significant role. It is positioned to monitor the pressure within the EGR valve and the recirculation passages. By providing real-time pressure data, the ECU can adjust the amount of exhaust gas being recirculated into the intake manifold. This helps in reducing nitrogen oxides (NOx) emissions and improving overall engine efficiency. The Pressure Sensing Tube ensures that the recirculation process is smooth and within the desired parameters, preventing issues such as engine knocking or inefficient combustion.

Contribution to Exhaust Systems

Within the exhaust system, the Pressure Sensing Tube is often used to monitor backpressure. This is particularly important in turbocharged engines where maintaining optimal exhaust flow is essential for turbocharger efficiency. The tube is typically installed in the exhaust manifold or just before the turbocharger. By measuring the backpressure, the ECU can make adjustments to the wastegate actuator, ensuring that the turbocharger operates within its designed parameters. This not only enhances performance but also protects the engine from potential damage due to over-boosting.

Enhanced System Performance

The accurate pressure readings provided by the Pressure Sensing Tube allow the ECU to fine-tune various engine parameters dynamically. For instance, in conjunction with the Mass Air Flow (MAF) sensor, it helps in achieving precise air-fuel ratio control. This is vital for both performance and emissions compliance. Additionally, in systems equipped with Variable Valve Timing (VVT), the pressure data can influence timing adjustments, leading to improved engine responsiveness and fuel economy.

Conclusion

The Cummins Pressure Sensing Tube Part #2882562 is an essential component in the operation of commercial trucks. Understanding its function, importance, and maintenance can help fleet operators and mechanics ensure the longevity and efficiency of their engines. By following the troubleshooting and maintenance tips provided, one can prevent potential issues and maintain optimal performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.