3062122

Hydraulic Variable Timing Tappet

Cummins®

DISCONTINUED

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

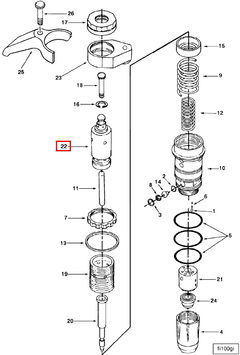

The Hydraulic Variable Timing Tappet (Part #3062122) by Cummins is a sophisticated component designed to enhance the performance and efficiency of heavy-duty truck engines. This tappet is integral to the engine’s valve timing system, allowing for dynamic adjustments that optimize engine operation under varying conditions.

Basic Concepts of Hydraulic Variable Timing Tappet

Hydraulic variable timing technology operates on the principle of altering valve timing to improve engine efficiency and performance. The Hydraulic Variable Timing Tappet achieves this by using hydraulic pressure to adjust the position of the camshaft relative to the crankshaft. This adjustment allows for precise control over the opening and closing of the engine’s valves, which in turn enhances combustion efficiency and reduces emissions 1.

Role and Function in Truck Engines

In heavy-duty truck engines, the Hydraulic Variable Timing Tappet plays a significant role by enabling the engine to adapt its valve timing based on operating conditions. This adaptability allows the engine to maintain optimal performance across a wide range of speeds and loads. By fine-tuning valve timing, the tappet contributes to improved fuel efficiency, reduced emissions, and enhanced overall engine performance 2.

Key Features

The Hydraulic Variable Timing Tappet is characterized by several key features that contribute to its effectiveness. Its design incorporates advanced hydraulic components that allow for precise control over camshaft positioning. The materials used in its construction are selected for durability and reliability, ensuring long-term performance in demanding environments. Additionally, technological advancements in hydraulic systems enhance the tappet’s responsiveness and accuracy.

Benefits

The advantages provided by the Hydraulic Variable Timing Tappet are substantial. Improved fuel efficiency is one of the primary benefits, as optimized valve timing leads to more efficient combustion. This, in turn, results in reduced fuel consumption and lower operating costs for truck operators. Additionally, the tappet contributes to reduced emissions by ensuring that the engine operates at peak efficiency, minimizing the production of harmful pollutants. Enhanced engine performance is another notable benefit, as the tappet allows the engine to deliver consistent power and torque under varying conditions 3.

Troubleshooting and Maintenance

Common issues that may arise with the Hydraulic Variable Timing Tappet include hydraulic leaks, worn components, and misalignment. Diagnostic procedures typically involve inspecting the hydraulic system for leaks, checking the tappet for signs of wear, and ensuring proper alignment with the camshaft and crankshaft. Regular maintenance practices, such as monitoring hydraulic fluid levels and replacing worn components, are essential to ensure optimal performance and longevity of the tappet.

Integration with Cummins Engines

The Hydraulic Variable Timing Tappet is seamlessly integrated into Cummins engine systems, designed to work in harmony with other engine components. Specific considerations for integration include ensuring compatibility with the engine’s hydraulic system and aligning the tappet with the camshaft and crankshaft. Cummins engines are engineered to leverage the benefits of variable timing technology, enhancing their overall performance and efficiency.

Historical Development

The evolution of hydraulic variable timing technology has been marked by significant milestones and innovations. Early developments focused on basic hydraulic systems to adjust valve timing, while more recent advancements have introduced sophisticated electronic controls and materials that improve durability and performance. The Hydraulic Variable Timing Tappet represents the culmination of these innovations, offering a reliable and efficient solution for modern heavy-duty truck engines.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins is committed to innovation and sustainability in the automotive industry. The company’s product portfolio includes engines for on-highway and off-highway applications, as well as power generation and industrial solutions. Cummins’ dedication to advancing technology and improving efficiency is evident in its development of components like the Hydraulic Variable Timing Tappet.

Compatibility with Cummins Engines

The Hydraulic Variable Timing Tappet, identified by the part number 3062122, is a critical component in the operation of several Cummins engines. This part is designed to manage the timing of the engine’s valve operation, ensuring optimal performance and efficiency. Below is a detailed description of its compatibility with various Cummins engines.

K-Series Engines

The Hydraulic Variable Timing Tappet is compatible with the following K-Series engines:

- K19

- K38

- K50

These engines benefit from the precise timing adjustments provided by the Hydraulic Variable Timing Tappet, enhancing their overall performance and reliability.

N-Series Engines

The Hydraulic Variable Timing Tappet is also suitable for the following N-Series engines:

- N14 MECHANICAL

This engine utilizes the Hydraulic Variable Timing Tappet to maintain optimal valve timing, contributing to its robust performance and durability.

NH/NT Series Engines

The Hydraulic Variable Timing Tappet is compatible with the following NH/NT Series engines:

- NH/NT 855

This engine model relies on the Hydraulic Variable Timing Tappet to ensure smooth and precise valve timing, enhancing its operational efficiency.

V-Series Engines

The Hydraulic Variable Timing Tappet is also suitable for the following V-Series engines:

- V903

- VTA903 CM2250 V105

These engines incorporate the Hydraulic Variable Timing Tappet to manage valve timing effectively, ensuring optimal performance and efficiency.

By integrating the Hydraulic Variable Timing Tappet into these engines, Cummins ensures that each engine model operates at its best, providing reliable and efficient performance across various applications.

Role of Part 3062122 Hydraulic Variable Timing Tappet in Engine Systems

The Part 3062122 Hydraulic Variable Timing Tappet is an integral component in modern engine systems, designed to enhance performance and efficiency. This component interacts with several key engine parts to optimize the overall functionality of the engine.

Interaction with Camshaft and Cam Follower Housing

The Hydraulic Variable Timing Tappet works in conjunction with the camshaft and cam follower housing. By adjusting the timing of the camshaft, it ensures that the valves open and close at the most efficient times relative to the piston’s position. This precise timing is essential for maximizing engine performance and fuel efficiency.

Coordination with Connecting Rod and Piston

In the engine’s combustion cycle, the connecting rod and piston assembly plays a vital role. The Hydraulic Variable Timing Tappet helps synchronize the valve timing with the piston’s movement. This synchronization ensures that the air-fuel mixture is introduced and expelled at optimal moments, enhancing combustion efficiency and power output.

Integration with Cylinder Head

The cylinder head houses the valves and plays a crucial role in the engine’s operation. The Hydraulic Variable Timing Tappet’s ability to adjust valve timing directly impacts the cylinder head’s performance. By fine-tuning the valve events, it contributes to better airflow, reduced emissions, and improved overall engine performance.

Compatibility with EBM-Injector and Injector Plumbing

For engines equipped with EBM-injector systems, the Hydraulic Variable Timing Tappet ensures that fuel delivery is perfectly timed with valve operations. This integration is particularly important in high-performance engines where precise fuel injection timing can significantly affect power output and efficiency. The injector plumbing must be meticulously designed to accommodate these timing adjustments, ensuring that the fuel is delivered at the exact moment needed for optimal combustion.

Enhancement of Performance Parts

In engines utilizing EBM: Performance Parts, the Hydraulic Variable Timing Tappet is a key component that enhances the performance of these parts. Whether it’s high-flow cylinder heads, upgraded camshafts, or performance pistons, the tappet’s ability to adjust timing ensures that all these components work in harmony, delivering maximum performance.

Fuel Connection and Tachometer Parts Kit

The fuel connection and components from the tachometer parts kit also benefit from the precise timing adjustments made by the Hydraulic Variable Timing Tappet. Accurate timing ensures that the engine operates smoothly, which is essential for the reliable functioning of these ancillary components.

Conclusion

In summary, the Part 3062122 Hydraulic Variable Timing Tappet is a sophisticated component that enhances the interaction between various engine parts, leading to improved performance, efficiency, and reliability. Its integration into Cummins engines ensures that each engine model operates at its best, providing reliable and efficient performance across various applications.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.