This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

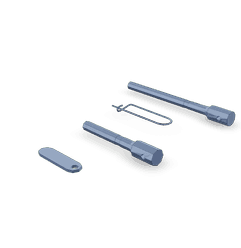

The Cummins 2892174 Timing Pin is a specialized component designed for use in heavy-duty truck engines. Its purpose is to ensure precise synchronization between the crankshaft and camshaft, which is vital for the efficient operation of the engine. This synchronization allows for optimal performance and reliability in demanding applications.

Basic Concepts of Timing Pins

Timing pins are small but crucial components in internal combustion engines. They serve to hold the crankshaft and camshaft in a fixed position relative to each other during engine maintenance or repair. This synchronization is necessary to ensure that the engine’s valves open and close at the correct times in relation to the pistons’ movements. Proper timing is fundamental to the engine’s efficiency, power output, and longevity 1.

Purpose of the Cummins 2892174 Timing Pin

The Cummins 2892174 Timing Pin plays a specific role in maintaining the correct timing between the crankshaft and camshaft in truck engines. By securing these components in place, it ensures that the engine’s timing is preserved during procedures such as belt or chain replacement. This helps in achieving consistent engine performance and prevents potential damage from timing misalignment.

Key Features

The Cummins 2892174 Timing Pin is characterized by its robust design and high-quality material composition. It is engineered to withstand the rigors of heavy-duty applications, ensuring durability and reliable performance. The pin’s precise dimensions and smooth surface finish contribute to its effectiveness in maintaining engine timing.

Benefits of Using the Cummins 2892174 Timing Pin

Utilizing the Cummins 2892174 Timing Pin offers several advantages. It contributes to improved engine performance by ensuring accurate timing, which is crucial for efficient combustion. Additionally, its reliable design enhances the engine’s reliability and longevity, reducing the likelihood of timing-related issues that could lead to costly repairs 2.

Installation Process

Installing the Cummins 2892174 Timing Pin requires careful attention to detail. The process involves aligning the crankshaft and camshaft to the specified timing marks, inserting the pin into the designated holes, and ensuring it is securely in place. Proper tools and equipment, such as a torque wrench, may be necessary to complete the installation correctly. Following manufacturer guidelines is recommended to ensure the pin is installed correctly.

Troubleshooting Common Issues

Common issues associated with timing pins include misalignment and wear. Misalignment can lead to incorrect engine timing, affecting performance and potentially causing damage. Wear on the pin or its mating surfaces can also compromise its effectiveness. Troubleshooting these issues involves inspecting the pin and related components for signs of damage or wear, and addressing any issues promptly to maintain engine performance.

Maintenance Tips

Regular maintenance of the Cummins 2892174 Timing Pin is important to ensure its continued effectiveness. This includes periodic inspection for signs of wear or damage, cleaning to remove any debris that could affect its function, and replacement when necessary. Adhering to recommended inspection intervals and maintenance procedures helps in preserving the engine’s timing and overall performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines. Their product range includes a variety of engine sizes and configurations, designed to meet the diverse needs of heavy-duty applications.

Understanding the Role of Part 2892174 Timing Pin in Engine Systems

The part 2892174 Timing Pin is an essential component in the synchronization of various engine systems. Its primary function is to ensure precise alignment between the crankshaft and camshaft during engine assembly or repair. This alignment is vital for the proper operation of the engine’s valve timing mechanism.

Integration with Engine Components

-

Crankshaft and Camshaft Alignment: The Timing Pin 2892174 is used to hold the crankshaft and camshaft in the correct positions relative to each other. This ensures that the pistons and valves operate in harmony, preventing interference that could lead to engine damage.

-

Valve Timing Mechanism: Proper valve timing is essential for engine efficiency and performance. The Timing Pin aids in setting the correct timing for the intake and exhaust valves, ensuring they open and close at the optimal moments in the engine cycle.

-

Tool Certification Kit: When used in conjunction with a Tool Certification Kit, the Timing Pin 2892174 helps verify that all tools and components are correctly aligned and certified for use. This kit often includes gauges and other instruments to ensure precision in engine assembly.

-

Engine Assembly and Repair: During engine assembly or repair, the Timing Pin is instrumental in maintaining the integrity of the timing belt or chain. It prevents the crankshaft and camshaft from rotating out of alignment, which is particularly important when replacing timing components.

-

Diagnostic and Maintenance Procedures: In diagnostic scenarios, the Timing Pin can be used to hold the engine in a specific position, allowing mechanics to perform detailed inspections and maintenance without the risk of components moving out of place.

By ensuring accurate alignment and synchronization, the Timing Pin 2892174 plays a significant role in the overall performance and longevity of the engine systems it is integrated with.

Conclusion

The Cummins 2892174 Timing Pin is a critical component in maintaining the precise synchronization between the crankshaft and camshaft in heavy-duty truck engines. Its robust design and high-quality material composition ensure durability and reliable performance. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential to preserve engine performance and longevity. Understanding the role of this part in engine systems highlights its importance in achieving optimal engine efficiency and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.