This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

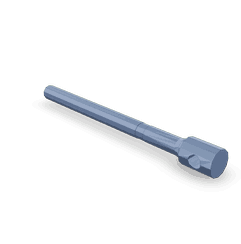

The Cummins 2892115 Timing Pin is a specialized component designed for use in heavy-duty truck engines. Its primary function is to ensure precise alignment of engine components during maintenance or repair procedures. This alignment is crucial for maintaining the engine’s timing, which directly influences the engine’s performance and longevity 1.

Basic Concepts of Timing Pins

Timing pins are small yet vital components within an engine. They serve to hold engine components in a fixed position, allowing for accurate timing adjustments. Proper engine timing is fundamental to the efficient operation of an engine, as it ensures that the fuel injection and valve operations occur at the correct moments in the engine cycle 2. Without accurate timing, engine performance can suffer, leading to decreased efficiency and potential damage.

Role of the Cummins 2892115 Timing Pin

The Cummins 2892115 Timing Pin plays a specific role in the engine’s operation by facilitating the alignment of critical engine components. During maintenance or repair, it is often necessary to disassemble parts of the engine. The timing pin helps to maintain the correct positional relationship between these components, ensuring that when the engine is reassembled, the timing is accurate. This is particularly important in heavy-duty engines where precise timing is crucial for optimal performance and durability 3.

Key Features

The Cummins 2892115 Timing Pin is engineered with several key features that enhance its performance and durability. Its design is tailored to fit snugly into the engine components it aligns, ensuring stability and accuracy. The material composition of the timing pin is selected for its strength and resistance to wear, which contributes to its longevity. Additionally, any unique attributes, such as a specific shape or coating, are designed to further improve its functionality and ease of use.

Benefits

Using the Cummins 2892115 Timing Pin offers several benefits. It contributes to improved engine performance by ensuring that engine components are correctly aligned, which is vital for maintaining accurate engine timing. This, in turn, enhances the reliability of the engine, reducing the likelihood of performance issues or damage. Furthermore, the design of the timing pin facilitates ease of use during maintenance procedures, making it a valuable tool for technicians working on heavy-duty trucks.

Troubleshooting and Maintenance

To ensure the longevity and optimal performance of the Cummins 2892115 Timing Pin, it is important to follow certain guidelines. Regular inspection for signs of wear or damage is recommended, as this can prevent issues that may arise from a faulty timing pin. In the event of troubleshooting common issues related to timing pins, such as misalignment or difficulty in insertion, verifying the condition of the pin and the components it interacts with can help identify and resolve the problem. Proper storage and handling of the timing pin are also important to maintain its integrity.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its products, including the Cummins 2892115 Timing Pin, which is designed to meet the demanding requirements of heavy-duty applications.

Role of Part 2892115 Timing Pin in Engine Systems

The part 2892115 Timing Pin is an essential component in the synchronization of various engine systems. It ensures that the camshaft and crankshaft are correctly aligned during engine assembly or repair. This alignment is fundamental for the proper functioning of the valve timing mechanism, which in turn affects the engine’s performance and efficiency.

Interaction with Engine Components

-

Camshaft and Crankshaft Alignment: The Timing Pin is inserted into specific locations on the camshaft and crankshaft. This prevents them from rotating independently, ensuring they are in the correct position relative to each other. Proper alignment is necessary for the valves to open and close at the right moments in the engine cycle.

-

Valve Train System: Accurate timing pin placement directly influences the valve train system. Misalignment can lead to valves opening at incorrect times, which can cause engine misfires, reduced power output, and potential damage to the pistons or valves.

-

Fuel Injection System: In engines equipped with fuel injection, the timing pin’s role becomes even more significant. Precise camshaft and crankshaft alignment ensures that the fuel injection timing is correct, optimizing combustion efficiency and reducing emissions.

-

Ignition System: For engines with spark ignition, the timing pin helps maintain the correct timing for spark delivery. This is vital for efficient combustion and overall engine performance.

Use with Tool Certification Kit

When employed alongside a Tool Certification Kit, the Timing Pin enhances the reliability of engine maintenance procedures. The kit often includes tools and gauges to verify the correct installation and function of the timing pin. This combination ensures that all components are correctly aligned and certified, providing an additional layer of assurance during engine repairs or overhauls.

Conclusion

In summary, the part 2892115 Timing Pin plays a significant role in maintaining the precise timing of engine components, which is essential for optimal engine performance and longevity. Its proper use and maintenance are critical for ensuring the reliability and efficiency of heavy-duty truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.