This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

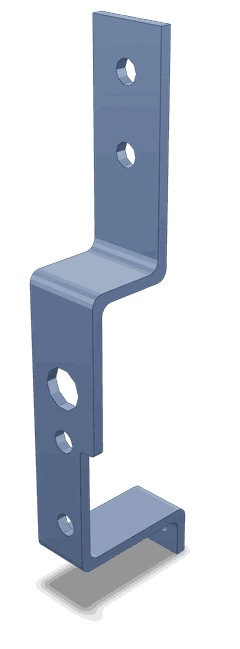

The Throttle Lever 3976441, manufactured by Cummins, is a component designed for use in commercial trucks. It plays a role in the operation of these vehicles by allowing precise control over engine performance. Cummins, a well-established name in the commercial truck industry, ensures that this throttle lever meets the high standards required for heavy-duty applications.

Basic Concepts of a Throttle Lever

A throttle lever is a mechanical component that regulates the amount of fuel and air entering an engine, thereby controlling its speed and power output 1. In a truck’s engine system, the throttle lever interacts with the fuel injection system and other components to modulate engine performance based on driver input. This regulation is important for maintaining optimal engine operation under varying load conditions.

Purpose of the 3976441 Throttle Lever

The 3976441 Throttle Lever is specifically designed to facilitate driver control over engine performance in commercial trucks. By adjusting the position of this lever, the driver can increase or decrease the engine’s power output, which is important for tasks such as accelerating, maintaining speed on inclines, or controlling the vehicle during descents. This lever allows for fine-tuned adjustments, enhancing the driver’s ability to manage the truck’s performance efficiently.

Key Features

The 3976441 Throttle Lever boasts several key features that enhance its functionality and durability. Its design incorporates high-quality materials that resist wear and tear, ensuring longevity in demanding environments. The lever’s ergonomic shape and smooth operation provide the driver with precise control over engine performance. Additionally, its robust construction allows it to withstand the vibrations and stresses inherent in heavy-duty truck operations.

Benefits

The use of the 3976441 Throttle Lever offers several benefits. It provides improved driver control over engine performance, allowing for more efficient operation of the truck. Enhanced engine performance is achieved through precise modulation of fuel and air intake, leading to better fuel efficiency and reduced emissions 2. Furthermore, the lever contributes to increased operational efficiency by enabling the driver to make quick and accurate adjustments to engine power, which is particularly beneficial in dynamic driving conditions.

Installation and Integration

Proper installation and integration of the 3976441 Throttle Lever within a truck’s engine system are vital for its optimal performance. Installation guidelines recommend ensuring that the lever is securely mounted and correctly aligned with the fuel injection system. Any necessary adjustments or configurations should be made according to the manufacturer’s specifications to ensure compatibility and proper function within the engine system.

Troubleshooting and Maintenance

To maintain the longevity and optimal performance of the 3976441 Throttle Lever, regular maintenance and troubleshooting practices are recommended. Common issues may include stiffness in the lever’s operation or misalignment, which can be addressed by lubricating moving parts or readjusting the lever’s position. Routine inspections for wear and damage are also advised to prevent more significant problems and ensure the lever continues to function effectively.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range and commitment to customer satisfaction have made it a preferred choice for commercial vehicle operators worldwide.

Throttle Lever 3976441 Compatibility with Cummins Engines

The Throttle Lever part number 3976441, manufactured by Cummins, is designed to interface seamlessly with a variety of Cummins engine models. This part is integral to the engine’s throttle control system, ensuring precise regulation of engine speed and power output.

Compatibility with Specific Engine Models

6B5.9 Engine Series

The 6B5.9 engine series benefits from the 3976441 Throttle Lever due to its robust design and compatibility with the engine’s throttle mechanism. This part ensures smooth and reliable operation, maintaining the engine’s performance standards.

L8.9 Engine Series

Similarly, the L8.9 engine series is well-suited for the 3976441 Throttle Lever. This part’s precision engineering aligns perfectly with the L8.9’s throttle system, providing consistent and dependable control over engine functions.

General Compatibility

The 3976441 Throttle Lever is engineered to fit within the broader Cummins engine family, ensuring that it can be used across multiple models with minimal adjustments. This versatility makes it a valuable component for technicians and operators who work with various Cummins engines.

By ensuring compatibility with the 6B5.9 and L8.9 engine series, the 3976441 Throttle Lever maintains the integrity and efficiency of the engine’s throttle control system.

Role of Throttle Lever in Engine Systems

The Throttle Lever, identified by part number 3976441, is an integral component in the regulation and control of engine performance. This lever is directly connected to the throttle valve, which modulates the airflow into the engine’s intake manifold. By adjusting the position of the throttle valve, the lever controls the amount of air entering the engine, which in turn affects the fuel mixture and the engine’s power output.

When the Throttle Lever is moved, it actuates the throttle valve through a series of linkages or cables. This mechanical action is important for the driver or pilot to manage the engine’s RPM (revolutions per minute) and torque. The lever’s movement is transmitted to the carburetor or fuel injection system, depending on the engine type, allowing for precise control over the air-fuel ratio.

In carbureted engines, the Throttle Lever opens the butterfly valve within the carburetor, allowing more air to enter. This increase in airflow draws in a corresponding amount of fuel, creating a richer mixture for combustion. In fuel-injected engines, the lever’s action signals the engine control unit (ECU) to adjust the fuel injectors’ operation, ensuring an optimal air-fuel ratio under varying throttle conditions 3.

Additionally, the Throttle Lever interacts with other systems such as the cruise control, where it maintains a consistent engine speed by modulating the throttle position. In automated or semi-automated transmissions, the lever’s input is used to determine gear changes based on the driver’s demand for acceleration or deceleration.

Overall, the Throttle Lever is a fundamental component that enables the operator to have direct and immediate control over the engine’s performance, ensuring that the power delivery is responsive and tailored to the operational requirements.

Conclusion

The 3976441 Throttle Lever by Cummins is a critical component for the efficient and precise control of engine performance in commercial trucks. Its robust design, compatibility with various Cummins engine models, and the benefits it offers in terms of fuel efficiency and operational efficiency make it a valuable asset for truck operators. Proper installation, regular maintenance, and understanding its role within the engine system are key to maximizing its performance and longevity.

-

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Hillier, Alma. Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press, 2014.

↩ -

Bonneau, Dominique, Aurelian Fatu, and Dominique Souchet. Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.