This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3048294 Throttle Lever is a critical component designed for commercial trucks, serving as the interface between the driver and the engine control system. This lever allows for the modulation of engine speed and power output, ensuring efficient and safe truck operation.

Basic Concepts of Throttle Levers

A throttle lever, whether mechanical or electronic, controls the amount of fuel entering an engine, thereby regulating its speed and power. It adjusts the position of the throttle plate within the carburetor or fuel injection system, influencing airflow into the engine and affecting combustion and power output 1.

Purpose and Role of the 3048294 Throttle Lever

This Cummins part is engineered to interface with Cummins engine control systems, providing a precise and responsive means for drivers to adjust engine performance. By moving the throttle lever, drivers can increase or decrease engine speed, which is essential for tasks such as accelerating, maintaining speed on inclines, or controlling the vehicle during descents 2.

Key Features

The 3048294 Throttle Lever is characterized by its robust design and high-quality materials, constructed to withstand the rigors of commercial truck operation. It features an ergonomic design for driver comfort and may include integrated sensors or electronic components that provide feedback to the engine control unit, refining engine performance 3.

Benefits of Using the Cummins 3048294 Throttle Lever

Utilizing this part offers improved engine control, allowing for precise modulation of engine speed and power. Its design and responsiveness enhance driver comfort and can contribute to potential increases in fuel efficiency and overall performance, making it valuable for commercial truck operators 4.

Installation and Compatibility

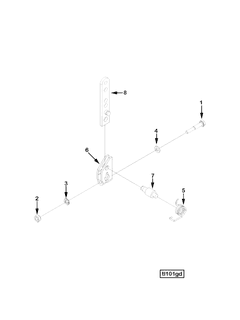

Proper installation of the 3048294 Throttle Lever is crucial for optimal performance and safety. Installation procedures vary by engine model but generally involve securing the lever to the appropriate mounting points and connecting it to the engine control system. It is compatible with a range of Cummins engine models, providing flexibility for various commercial truck applications 5.

Maintenance and Troubleshooting

Regular maintenance of the 3048294 Throttle Lever is essential for reliable operation. Maintenance procedures may include periodic inspection for wear or damage, cleaning to remove dirt or debris, and lubrication of moving parts to prevent stiffness or malfunction. Common issues can be addressed through cleaning, lubrication, or replacement of worn components 6.

Safety Considerations

When working with the 3048294 Throttle Lever, it is important to observe safety practices, including ensuring the engine is turned off and cooled before beginning any work, using appropriate personal protective equipment, and following all manufacturer guidelines for installation and maintenance. Proper handling and secure installation are crucial to prevent accidents or injuries during operation 7.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its products, such as the 3048294 Throttle Lever, designed to meet the demanding requirements of commercial truck operators 8.

Throttle Lever 3048294 Compatibility with Cummins Engines

The Throttle Lever part number 3048294 is designed to fit a variety of Cummins engines, ensuring smooth and precise control of the engine’s throttle. This part is integral to the operation of several engine models, providing a reliable interface between the operator and the engine’s throttle mechanism.

K-Series Engines

The Throttle Lever 3048294 is compatible with the following K-Series engines:

- K19

- K38

- K50

These engines are known for their robust construction and efficiency, often used in heavy-duty applications. The throttle lever ensures that the operator can effectively manage the engine’s power output, crucial for maintaining performance in demanding environments.

L-Series Engines

For the L-Series engines, the throttle lever fits the:

- L10 MECHANICAL

The L10 MECHANICAL engine is designed for applications requiring a balance of power and reliability. The throttle lever’s precision ensures that the engine responds accurately to operator inputs, enhancing overall performance.

M-Series Engines

The Throttle Lever 3048294 is also compatible with the following M-Series engines:

- M11 CELECT PLUS

- M11 MECHANICAL

Both the M11 CELECT PLUS and M11 MECHANICAL engines benefit from the throttle lever’s design, which provides smooth and responsive control. These engines are widely used in various applications, from construction to transportation, where reliable throttle control is essential.

N-Series Engines

The N-Series engine that is compatible with the throttle lever is:

- N14 MECHANICAL

The N14 MECHANICAL engine is known for its high power output and durability. The throttle lever ensures that the engine’s power can be managed effectively, making it suitable for heavy-duty applications.

NH/NT Series Engines

The NH/NT 855 engine is also compatible with the throttle lever part number 3048294. This engine is designed for applications that require a combination of power and efficiency, and the throttle lever plays a crucial role in delivering precise control.

V-Series Engines

The V-Series engines that fit the throttle lever include:

- V28

- V903

These engines are known for their high performance and reliability. The throttle lever ensures that the engine’s power can be managed with precision, making it suitable for a wide range of applications, from industrial to marine.

By ensuring compatibility with these various engines, the Cummins Throttle Lever 3048294 provides a reliable and precise control mechanism, enhancing the overall performance and efficiency of the engines it is used with.

Role of Part 3048294 Throttle Lever in Engine Systems

The Throttle Lever, identified by part number 3048294, is an integral component in the orchestration of engine performance. It acts as the physical interface between the operator and the engine’s throttle system, translating manual inputs into precise adjustments of the engine’s power output.

When the operator moves the Throttle Lever, this action is transmitted through a series of linkages and cables to the carburetor or fuel injection system. In carburetor-equipped engines, the lever directly influences the position of the throttle plate, which regulates the airflow into the engine. This, in turn, controls the amount of fuel that is mixed with the air, thereby adjusting the engine’s RPM and power.

In fuel-injected engines, the Throttle Lever’s movement is detected by a throttle position sensor (TPS). The TPS sends a signal to the engine control unit (ECU), which then adjusts the fuel injection timing and quantity to match the desired engine load. This ensures that the engine operates efficiently across a range of conditions.

The Throttle Lever also interacts with other systems such as the cruise control, where it sets a reference point for the system to maintain a constant speed. Additionally, in automated or semi-automated transmission systems, the position of the Throttle Lever can influence gear changes, optimizing performance and fuel economy.

Overall, the Throttle Lever is a key component that ensures the engine responds accurately to the operator’s commands, maintaining a balance between performance and efficiency.

Conclusion

The Cummins 3048294 Throttle Lever is a vital component in the operation of commercial trucks, providing a precise and responsive means for drivers to adjust engine performance. Its robust design, compatibility with various Cummins engines, and integration with engine control systems make it an essential part for ensuring efficient and safe truck operation.

-

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Drozdziel, Pawel. The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge, 2023.

↩ -

Cummins Inc. QSK23 CM2350 K127, Service Manual (5504160).

↩ -

Cummins Inc. QSK23 CM2350 K127, Service Manual (5504160).

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ -

Cummins Inc. QSK23 CM2350 K127, Service Manual (5504160).

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.