This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

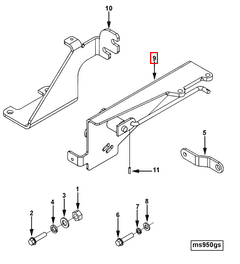

The Throttle Control Bracket, identified by Part #4929699, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This bracket is integral to the operation of trucks, facilitating the control and regulation of the engine’s throttle. Understanding its role and functionality is key to maintaining optimal truck performance.

Function and Operation

The Throttle Control Bracket operates within the truck’s engine system by securing the throttle linkage, which connects the accelerator pedal to the engine’s throttle mechanism. This bracket ensures that the throttle linkage remains in the correct position, allowing for precise control of the engine’s speed and power output. It interacts with various components, including the accelerator pedal, throttle linkage, and the engine’s throttle body, to facilitate smooth and responsive acceleration.

Purpose of the Throttle Control Bracket

The Throttle Control Bracket plays a role in the truck’s operation by providing a stable mounting point for the throttle linkage. This stability is crucial for maintaining consistent engine performance and control. By securing the throttle linkage, the bracket contributes to the accurate transmission of driver inputs to the engine, ensuring that the throttle responds appropriately to changes in pedal position.

Key Features

The Throttle Control Bracket is designed with several key features that enhance its functionality. It is typically made from durable materials such as steel or aluminum, ensuring longevity and resistance to wear 1. The design includes mounting points for secure attachment to the truck’s chassis and precise alignment with the throttle linkage. Additionally, the bracket may feature corrosion-resistant coatings to protect against environmental factors, extending its service life.

Benefits

The advantages provided by the Throttle Control Bracket include improved engine efficiency, as it ensures that the throttle linkage operates within specified parameters. This results in more consistent engine performance and better fuel economy. The durable construction of the bracket contributes to its longevity, reducing the need for frequent replacements. Furthermore, its design allows for straightforward installation and maintenance, minimizing downtime and repair costs.

Installation Process

Proper installation of the Throttle Control Bracket involves several steps. First, the truck’s engine compartment should be accessed, and the existing bracket (if any) should be removed. The new bracket should then be positioned according to the manufacturer’s guidelines, ensuring alignment with the throttle linkage and mounting points on the chassis. Secure the bracket using the provided fasteners, taking care to tighten them to the specified torque settings. Finally, test the throttle operation to confirm that the linkage moves freely and the engine responds correctly to pedal inputs.

Common Issues and Troubleshooting

Typical problems associated with the Throttle Control Bracket may include misalignment, wear, or corrosion. Misalignment can lead to improper throttle operation, while wear or corrosion may compromise the bracket’s structural integrity. Troubleshooting these issues involves inspecting the bracket for signs of damage or wear, ensuring proper alignment with the throttle linkage, and applying corrosion-resistant treatments if necessary. In cases of severe wear or damage, replacement of the bracket may be required.

Maintenance Tips

To ensure the longevity and optimal performance of the Throttle Control Bracket, regular maintenance practices should be followed. This includes periodic inspection for signs of wear, corrosion, or misalignment. Cleaning the bracket and applying corrosion-resistant coatings can help protect it from environmental factors. Additionally, ensuring that the throttle linkage is properly lubricated and adjusted can contribute to the smooth operation of the throttle system.

Compatibility and Usage

Information on the types of trucks and engine models compatible with the Throttle Control Bracket, and any specific usage guidelines, will be provided separately to ensure accurate and up-to-date details.

Safety Considerations

When handling and working with the Throttle Control Bracket, it is important to observe safety protocols and precautions. This includes wearing appropriate personal protective equipment, ensuring that the engine is turned off and cool before beginning any work, and following the manufacturer’s guidelines for installation and maintenance. Additionally, always refer to the truck’s service manual for specific safety instructions related to the throttle system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation.

Role of Part 4929699 Throttle Control Bracket in Engine Systems

The Throttle Control Bracket, identified by part number 4929699, serves as a pivotal component in the orchestration of engine performance through its interaction with the control and manual throttle lever systems.

Interaction with Control Systems

In automated engine control systems, the Throttle Control Bracket acts as a mounting point for sensors and actuators. It facilitates the precise positioning of these components, ensuring they can effectively monitor and adjust the throttle position in response to engine load, speed, and other operational parameters. This bracket allows for the secure attachment of throttle position sensors, which are essential for the Engine Control Unit (ECU) to receive accurate data on throttle opening. Consequently, the ECU can make real-time adjustments to fuel delivery and ignition timing, optimizing engine performance and efficiency.

Integration with Manual Throttle Lever

For engines equipped with manual throttle control, the Throttle Control Bracket provides a stable foundation for the manual throttle lever. It ensures that the lever’s movement is translated accurately into throttle position changes. The bracket’s design accommodates the mechanical linkage between the lever and the throttle body, allowing for smooth and responsive throttle operation. This is particularly important in applications where precise control over engine speed and power output is required, such as in aviation or marine engines.

Conclusion

In summary, the Throttle Control Bracket (part 4929699) is integral to both automated and manual throttle systems, ensuring that throttle adjustments are communicated effectively to the engine, thereby maintaining optimal performance across a range of operating conditions.

-

Yushu Wang, Introduction to Engine Valvetrains, SAE International, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.