4951626

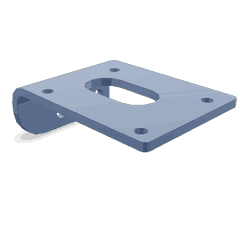

Throttle Control Bracket

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Throttle Control Bracket 4951626 is a component designed to facilitate the operation of heavy-duty trucks. Manufactured by Cummins, a well-regarded name in the automotive industry, this bracket plays a role in the truck’s engine system by regulating the throttle, ensuring that the engine operates smoothly and efficiently. Understanding the purpose and significance of this Cummins part is fundamental for maintaining and optimizing the performance of heavy-duty trucks.

Function and Operation

This part operates within the truck’s engine system by connecting the throttle linkage to the engine. This connection allows for precise control over the throttle, which in turn regulates the amount of air and fuel entering the engine. By maintaining a consistent and appropriate throttle setting, the bracket contributes to the smooth operation of the engine, enhancing overall performance and efficiency.

Key Features

The Throttle Control Bracket 4951626 is constructed from durable materials, ensuring longevity and reliability under demanding conditions. Its design incorporates several key features, including a robust mounting system that secures the bracket firmly in place, reducing the risk of movement or misalignment. Additionally, the bracket is engineered with precision to ensure accurate throttle control, which is vital for the consistent performance of the engine.

Benefits

The advantages of using the Throttle Control Bracket 4951626 include improved engine efficiency, as it allows for fine-tuned throttle control. This precision contributes to better fuel economy and reduced emissions. The bracket’s durable construction ensures enhanced durability, making it suitable for use in various operating conditions. Furthermore, its reliable performance helps in maintaining the overall efficiency and reliability of the truck’s engine system.

Installation Process

Installing the Throttle Control Bracket 4951626 requires careful attention to detail. The process involves securing the bracket to the engine using the provided mounting hardware. It is important to ensure that the bracket is aligned correctly with the throttle linkage to guarantee proper function. Tools required for installation may include a torque wrench and socket set. Following the manufacturer’s guidelines for torque specifications is recommended to prevent over-tightening or under-tightening of the fasteners.

Maintenance and Troubleshooting

To ensure optimal performance, regular maintenance of the Throttle Control Bracket 4951626 is advised. This includes checking for any signs of wear or damage, ensuring that all fasteners are secure, and verifying that the throttle linkage is operating smoothly. Common issues may include misalignment or wear on the bracket, which can affect throttle control. Troubleshooting steps involve inspecting the bracket and linkage for any abnormalities and making necessary adjustments or replacements as needed.

Safety Considerations

When working with the Throttle Control Bracket 4951626, it is important to observe safety guidelines. This includes ensuring that the engine is turned off and cooled down before beginning any work. Using appropriate personal protective equipment, such as gloves and safety glasses, is recommended. Additionally, following the manufacturer’s instructions for installation and maintenance will help ensure safe and effective use of the bracket.

Cummins Overview

Cummins Inc. is a leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a strong reputation in the automotive industry, Cummins is committed to producing high-quality components that enhance the performance and reliability of heavy-duty trucks. Their extensive experience and dedication to innovation make them a trusted provider of truck components, including the Throttle Control Bracket 4951626.

Compatibility with Cummins Engines

The Throttle Control Bracket, identified by the part number 4951626, is designed to securely mount and position the throttle control mechanism, ensuring precise and reliable engine operation. Below is a detailed overview of its compatibility with specific Cummins engines.

QSK60 and QSK60 G Engines

The Throttle Control Bracket (4951626) is specifically engineered to fit the QSK60 and QSK60 G engines. These engines are known for their robust performance and are widely used in various industrial applications. The bracket’s design ensures that the throttle linkage is properly aligned, which is essential for maintaining optimal engine performance and efficiency.

CM2358 and K110 Engines

Similarly, the Throttle Control Bracket (4951626) is also compatible with the CM2358 and K110 engines. These engines are part of Cummins’ extensive lineup, each tailored for specific applications ranging from marine to construction and power generation. The bracket’s precision fitment is critical in these engines, as it directly affects the responsiveness and reliability of the throttle system.

Installation and Functionality

While the specific design and installation process of the Throttle Control Bracket may vary slightly between engine models, the fundamental purpose remains the same: to provide a stable and secure mounting point for the throttle linkage. This ensures that the throttle can be operated smoothly and accurately, which is vital for both performance and safety.

Importance of Proper Fitment

The correct fitment of the Throttle Control Bracket is essential for the overall functionality of the engine. An improperly installed bracket can lead to misalignment of the throttle linkage, resulting in reduced engine performance, increased wear, and potential safety hazards. Therefore, it is crucial to use the correct bracket for each specific engine model to ensure optimal operation.

Role of Throttle Control Bracket in Engine Systems

The Throttle Control Bracket, part 4951626, is integral to the operation of various engine systems, ensuring precise control and efficient performance.

Integration with the Governor

In engines equipped with a governor, the Throttle Control Bracket serves as a pivotal connection point. It secures the throttle linkage to the governor mechanism, allowing for the modulation of engine speed in response to load changes. This bracket ensures that the governor can effectively adjust the throttle position, maintaining consistent engine performance under varying conditions.

Interaction with Electronic Systems

For engines with electronic control systems, the Throttle Control Bracket plays a key role in interfacing mechanical components with electronic sensors and actuators. It provides a stable mounting point for the throttle position sensor (TPS), which monitors the throttle’s opening angle and sends data to the engine control unit (ECU). This data is essential for the ECU to make real-time adjustments to fuel delivery and ignition timing, optimizing engine efficiency and performance.

Connection to the Valve

The Throttle Control Bracket also connects to the throttle valve, which regulates the airflow into the engine. By securing the throttle linkage to the valve, the bracket ensures that the valve opens and closes smoothly in response to driver input or automated control signals. This precise control over airflow is vital for maintaining the correct air-fuel mixture, which is fundamental to engine operation.

Throttle Control and Engine Performance

Overall, the Throttle Control Bracket is a fundamental component in the throttle control system. It ensures that the throttle linkage, governor, electronic sensors, and throttle valve work in harmony. This integration allows for accurate throttle control, which is essential for smooth engine operation, efficient fuel consumption, and responsive performance.

Conclusion

The Throttle Control Bracket 4951626 by Cummins is a critical component in the operation of heavy-duty trucks, ensuring precise throttle control and efficient engine performance. Its compatibility with various Cummins engines, including the QSK60, QSK60 G, CM2358, and K110, underscores its versatility and importance. Proper installation, maintenance, and understanding of its role in engine systems are essential for optimal truck performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.