Introduction

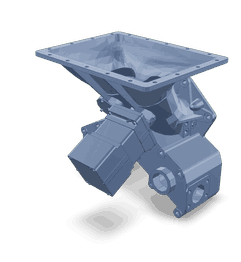

The Cummins 4015157 Throttle Valve is engineered to regulate the airflow into the engine of commercial trucks. This component controls the amount of air entering the engine, which directly influences the air-fuel mixture and, consequently, the engine’s performance. The throttle valve’s ability to modulate engine power output and efficiency contributes to the overall functionality and reliability of the vehicle.

Basic Concepts of Throttle Valves

A throttle valve, also known as a throttle body, is a device in an internal combustion engine that controls the airflow into the engine. By adjusting the position of the throttle plate within the valve, it regulates the volume of air entering the engine. This regulation is essential for maintaining the proper air-fuel ratio, which is necessary for efficient combustion. The throttle valve’s role in controlling this mixture ensures that the engine operates within its optimal performance range under varying conditions 1.

Role of the 4015157 Throttle Valve in Truck Operation

The Cummins 4015157 Throttle Valve plays a specific role in the operation of commercial trucks by precisely controlling the airflow into the engine. This control allows for adjustments in engine speed and power output, which are important for the truck’s performance across different driving conditions. The throttle valve interacts with other engine components, such as the fuel injection system, to ensure that the engine receives the correct amount of fuel for the given airflow, thus optimizing combustion efficiency and power delivery 2.

Key Features of the 4015157 Throttle Valve

The design and construction of the Cummins 4015157 Throttle Valve incorporate several features that contribute to its performance and durability. These include a robust construction that can withstand the high temperatures and pressures within the engine compartment, precise engineering to ensure accurate airflow control, and materials selected for their resistance to wear and corrosion. These features collectively enhance the valve’s reliability and longevity in demanding commercial truck applications.

Benefits of Using the 4015157 Throttle Valve

Utilizing the Cummins 4015157 Throttle Valve offers several advantages. It contributes to improved engine efficiency by ensuring an optimal air-fuel mixture, which can lead to better fuel economy. Enhanced performance is another benefit, as the precise control of airflow allows for more responsive engine operation. Additionally, the reliability of the throttle valve is important for maintaining consistent engine performance over time, reducing the likelihood of unexpected failures.

Installation and Integration

Proper installation and integration of the Cummins 4015157 Throttle Valve into a truck’s engine system require adherence to manufacturer guidelines. This includes ensuring a secure fit within the engine’s intake system, proper alignment with other components, and correct electrical connections if the valve is electronically controlled. Careful attention to these details during installation helps ensure the valve functions as intended, contributing to the engine’s overall performance and reliability.

Common Issues and Troubleshooting

Throttle valves, including the Cummins 4015157, may encounter issues such as sticking, leaking, or electronic malfunctions. These problems can affect engine performance and should be addressed promptly. Troubleshooting steps may involve cleaning the valve, checking for obstructions, or inspecting electrical connections. In some cases, replacement of the valve may be necessary to restore optimal engine operation.

Maintenance Tips

Routine maintenance practices can help ensure the longevity and optimal performance of the Cummins 4015157 Throttle Valve. These include regular inspection for signs of wear or damage, cleaning to remove any buildup that could affect operation, and ensuring all connections are secure and free from corrosion. Following the manufacturer’s recommended maintenance schedule can help prevent issues and extend the service life of the throttle valve.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle applications. Cummins’ commitment to excellence and customer satisfaction has made it a preferred choice among commercial truck operators and manufacturers.

Conclusion

The Cummins 4015157 Throttle Valve is a critical component in the engine’s fuel management system, ensuring precise control over the engine’s air intake. Its integration with the Cummins QSV81G and QSV91G engines demonstrates Cummins’ commitment to providing high-quality components that enhance engine performance and durability. Proper installation, maintenance, and understanding of its role in the engine system are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.